Cloud MES software

Cloud MES software is transforming modern production control. It gives you real-time insight into machines, lines and orders – without the complexity, cost and delay of traditional MES projects.

Traditional on-premise MES systems tie up valuable IT resources, generate high maintenance costs and slow down critical innovation cycles.

SYMESTIC gives you the future-proof alternative: a high-performance cloud MES software, purpose-built for the needs of mid-sized manufacturers and production teams that want fast results instead of long IT projects.

Why Cloud MES software?

Cloud MES is not just a different deployment model – it is a new way of running a manufacturing execution system: faster rollout, lower risk and a platform that keeps improving automatically.

| Traditional MES (on-premise) | Cloud MES (with SYMESTIC) |

|---|---|

| Months until the system goes live | Live in as little as 3 hours |

| High upfront investments in servers, databases and consulting | No capital expenditures – subscription pricing per plant |

| Strong dependency on local IT capacity and know-how | Fully managed and maintenance-free in the cloud |

| Complex updates and time-consuming migrations | Automatic, seamless updates with new MES features delivered continuously |

| Static, inflexible license models | Flexible, usage-based scaling per plant and production network |

.png?width=1792&height=1024&name=Lean-Production%20(3).png)

Who benefits most from Cloud MES?

Our customers see the biggest impact from Cloud MES in situations like these:

• You have no dedicated IT team on the shop floor and still need a professional MES solution.

• Your plants are distributed internationally and you want one central MES platform for all sites.

• You want to run a fast MES pilot – with real machines and data – but without financial risk.

• You need a modern MES solution that scales with new lines, products and locations instead of blocking them.

How Cloud MES with SYMESTIC works

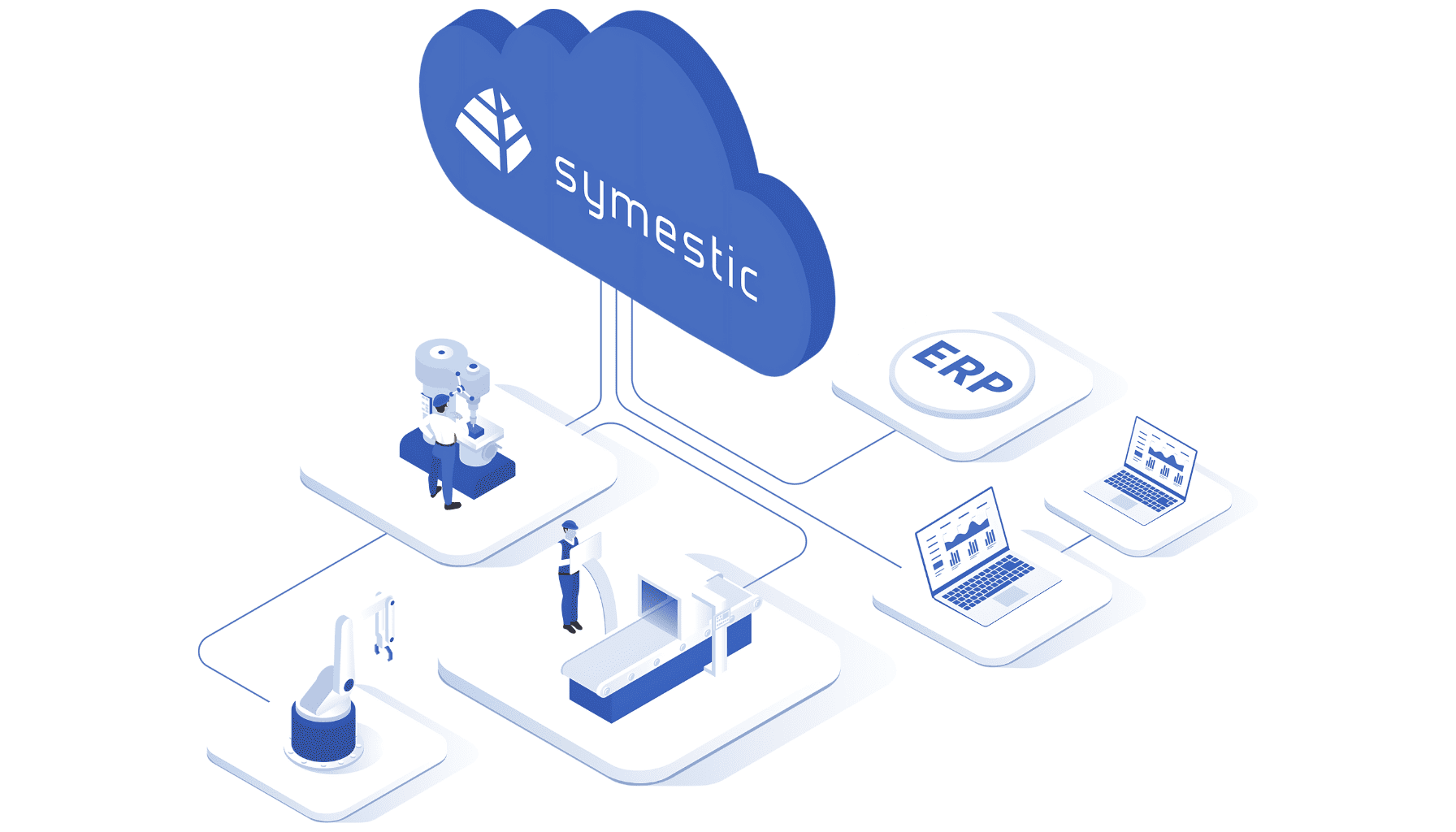

SYMESTIC was designed as a cloud-first manufacturing platform — secure, scalable, and plug-and-play.

1. Data capture at the machine

Industrial edge devices collect machine states, alarms, and process values in real time.

2. Secure data transfer

Encrypted transmission into the trusted Microsoft Cloud, compliant with all industrial IT/OT standards.

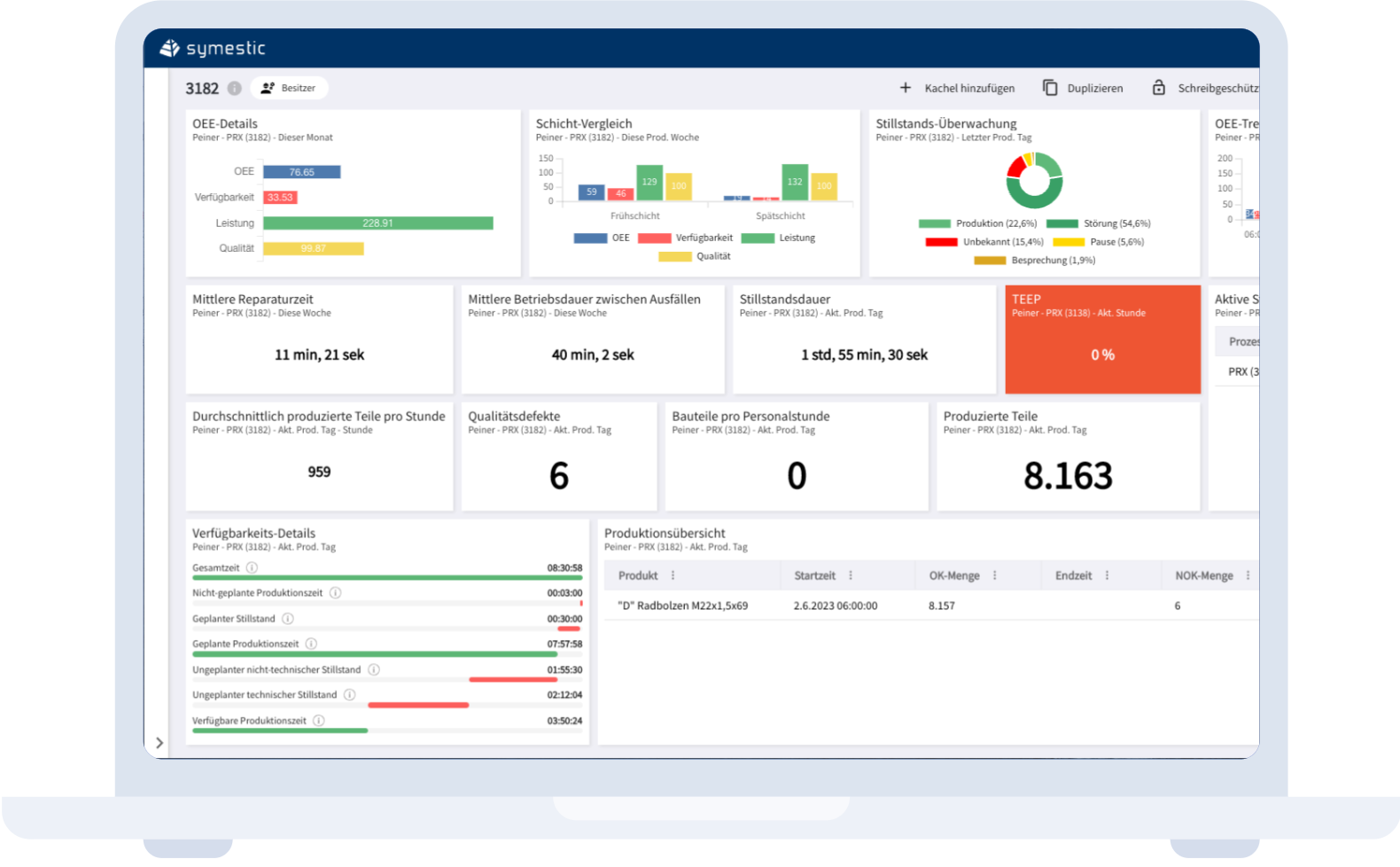

3. Visualization and control

Access live dashboards and KPIs from any device and location — directly via browser.

4. Real-time performance insights

Track OEE, downtime, alarms, and quality metrics in one integrated MES environment.