Production Digitalization: The Fastest Path to a Smart Factory

Production digitalization gives manufacturers real-time transparency, automated workflows and stable, data-driven operations.

With SYMESTIC, you connect machines within hours and transform fragmented shop floors into integrated, high-performing production environments without IT projects or downtime.

Core Elements of Modern Production Digitalization

Real-time data acquisition:

Machines and sensors continuously stream status, quality signals and process parameters.

This creates a single source of truth for all teams and forms the foundation of every digital initiative.

Automated workflows:

Paper processes disappear. Order changes, disruptions and approvals flow automatically across planning, production and quality.

ERP/MES integration ensures seamless communication and zero information loss.

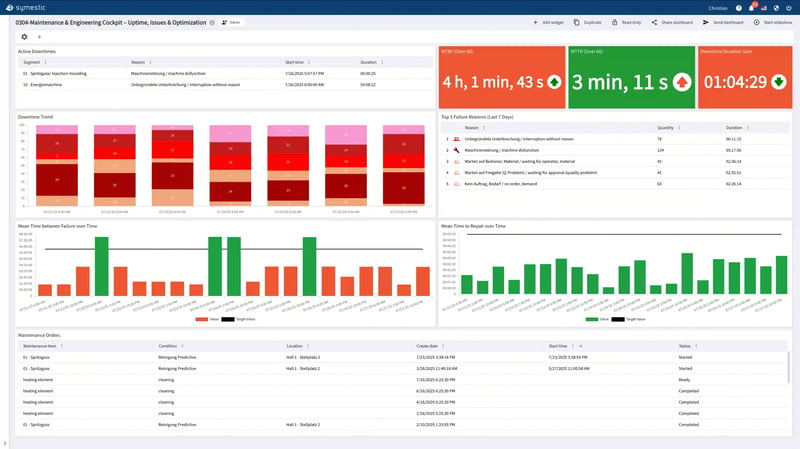

Predictive analytics:

Historical and live data reveal trends and deterioration patterns early.

This enables predictive maintenance, stable processes and higher equipment availability.

The SYMESTIC Cloud MES Platform

Plug-and-play installation:

Machines are connected without modifying controls. No production stop, no IT dependency — simply plug in and start receiving live OEE, downtime and process data.

Scalable architecture:

From one pilot line to global rollout — SYMESTIC grows with your operations and provides consistent standards across all plants.

Enterprise-grade security & standards:

Built on ISA-95 and cloud-native infrastructure, the platform ensures robust cybersecurity, safe integrations and continuous updates.

Start Digitalizing Your Production Today

Enable real-time insights, eliminate manual processes and stabilize your production with a cloud-native digital platform.

Start your free 30-day trial and see measurable impact within hours.