Improve Machine Availability – Unlock Maximum Production Uptime

Every unplanned stoppage reduces output, creates delays, and increases cost per unit. To improve machine availability, manufacturers need real-time transparency, clear root-cause insights, and actionable measures that can be implemented without delay.

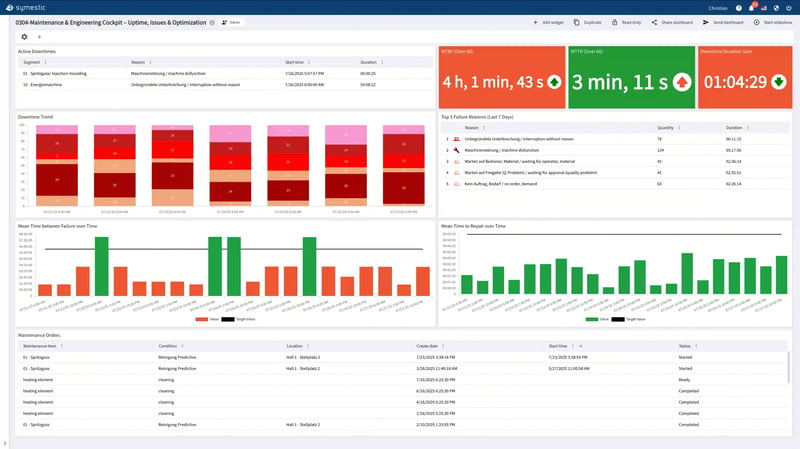

With SYMESTIC, companies increase availability measurably and sustainably — supported by automated data capture, early warnings, and continuous performance monitoring.

Why Machine Availability Matters

High availability means stable processes, fewer interruptions, and predictable daily output. Reliable machines reduce unplanned downtime, optimize maintenance timing, and significantly increase OEE, cost efficiency, and delivery reliability.

When availability drops, it is usually due to recurring disruptions, long setups, lack of spare parts, or missing early detection of developing issues.

Without real-time insights, these losses remain hidden and teams react far too late.

How SYMESTIC Helps You Increase Machine Availability

SYMESTIC provides continuous, automatic machine data acquisition and transforms it into clear, real-time insights.

Early warning systems notify teams at the first sign of deviation so issues can be addressed before downtime escalates.

Maintenance planning becomes data-driven, based on actual machine runtimes rather than fixed intervals.

Root-cause analysis reveals exactly which disturbances reduce uptime, allowing targeted actions instead of broad assumptions.

Predictive maintenance functionalities help detect emerging failures early and prevent critical breakdowns entirely.

Real-Time Visibility That Drives Better Decisions

SYMESTIC gives production teams, maintenance, and management one shared, factual view of machine behavior.

Availability trends become visible instantly, helping stabilize the entire production flow.

Bottlenecks can be identified at the moment they arise, and cross-shift comparisons uncover operational patterns that impact uptime.

This real-time transparency creates a consistent basis for improvement and supports faster, smarter decision-making.

Start Improving Machine Availability Today

Experience how real-time visibility and actionable insights increase uptime, reduce downtime, and strengthen production reliability.

Start your free SYMESTIC trial and unlock your full machine availability potential.