Kaizen Software

SYMESTIC Kaizen Software enables continuous improvement directly at the shop floor with real-time data, transparent workflows and fast execution.

Teams capture deviations, improvement ideas and actions instantly, creating a measurable improvement culture without paperwork or Excel chaos.

What Kaizen Software Does

Kaizen stands for continuous, incremental improvement. SYMESTIC brings this principle into a digital environment where all ideas, root causes and actions are captured, evaluated and tracked in real time.

Operators document insights immediately via tablet or workstation. Improvement actions are assigned automatically, deadlines are clear, and progress becomes visible for everyone.

The result is a structured, repeatable improvement process that removes friction and accelerates impact across all production lines.

Why Digital Kaizen Support Matters

Manual Kaizen workflows slow teams down. Paper forms get lost, responsibilities are unclear, and follow-up often breaks down.

SYMESTIC eliminates these gaps with centralized idea management, automatic notifications and real-time status tracking.

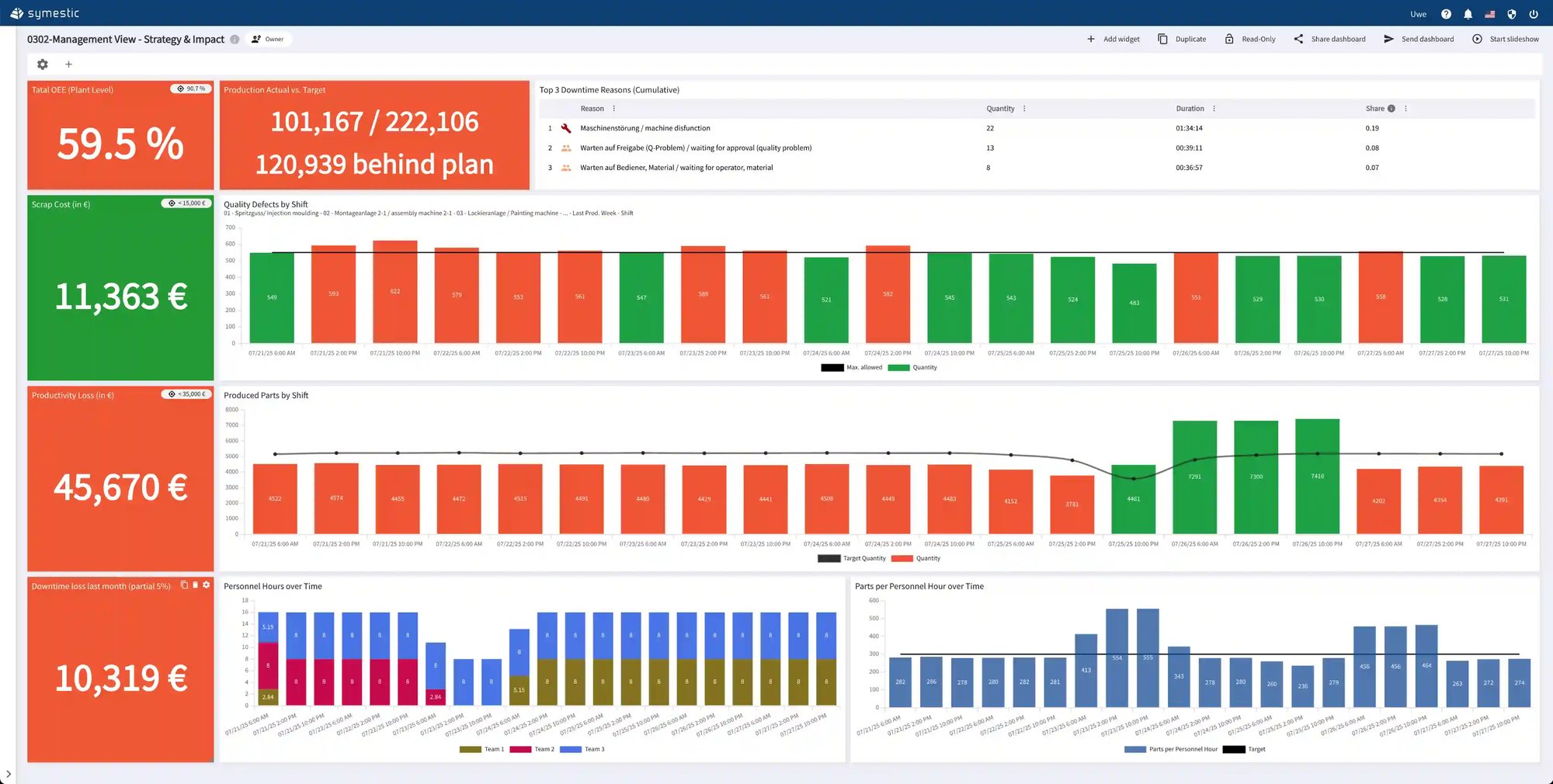

Every improvement becomes traceable, measurable and aligned with actual production data such as downtime, quality events or OEE losses.

Digital Kaizen transforms scattered initiatives into a continuous, data-driven improvement system.

Continuous Improvement Powered by Real-Time Production Data

The SYMESTIC platform connects Kaizen initiatives directly with machine and process data.

Teams understand instantly where losses occur, why they happen and which improvement action delivers the highest impact.

Root-cause analysis, KPIs and digital shopfloor boards give teams the transparency they need to drive lean improvements every day.

This real-time connection ensures that Kaizen is not theoretical—but operational, measurable and aligned with production priorities.

Benefits for Your Organization

Companies using SYMESTIC Kaizen Software see more active employee participation, faster implementation of actions and higher ROI per improvement initiative.

Decision-makers gain transparency, team leads gain clarity, and operators gain a direct voice in the improvement process.

Continuous improvement becomes part of daily production—structured, digital and measurable.