Lean Manufacturing System

A Lean Manufacturing System eliminates waste, stabilizes processes and drives continuous improvement across all production areas.

The SYMESTIC Cloud MES digitizes lean principles and makes efficiency gains measurable from day one.

Start your free trial and implement lean manufacturing with a structured, data-driven approach.

A Digital Lean Manufacturing System as a Performance Driver

Traditional lean initiatives often remain superficial when executed without real-time data.

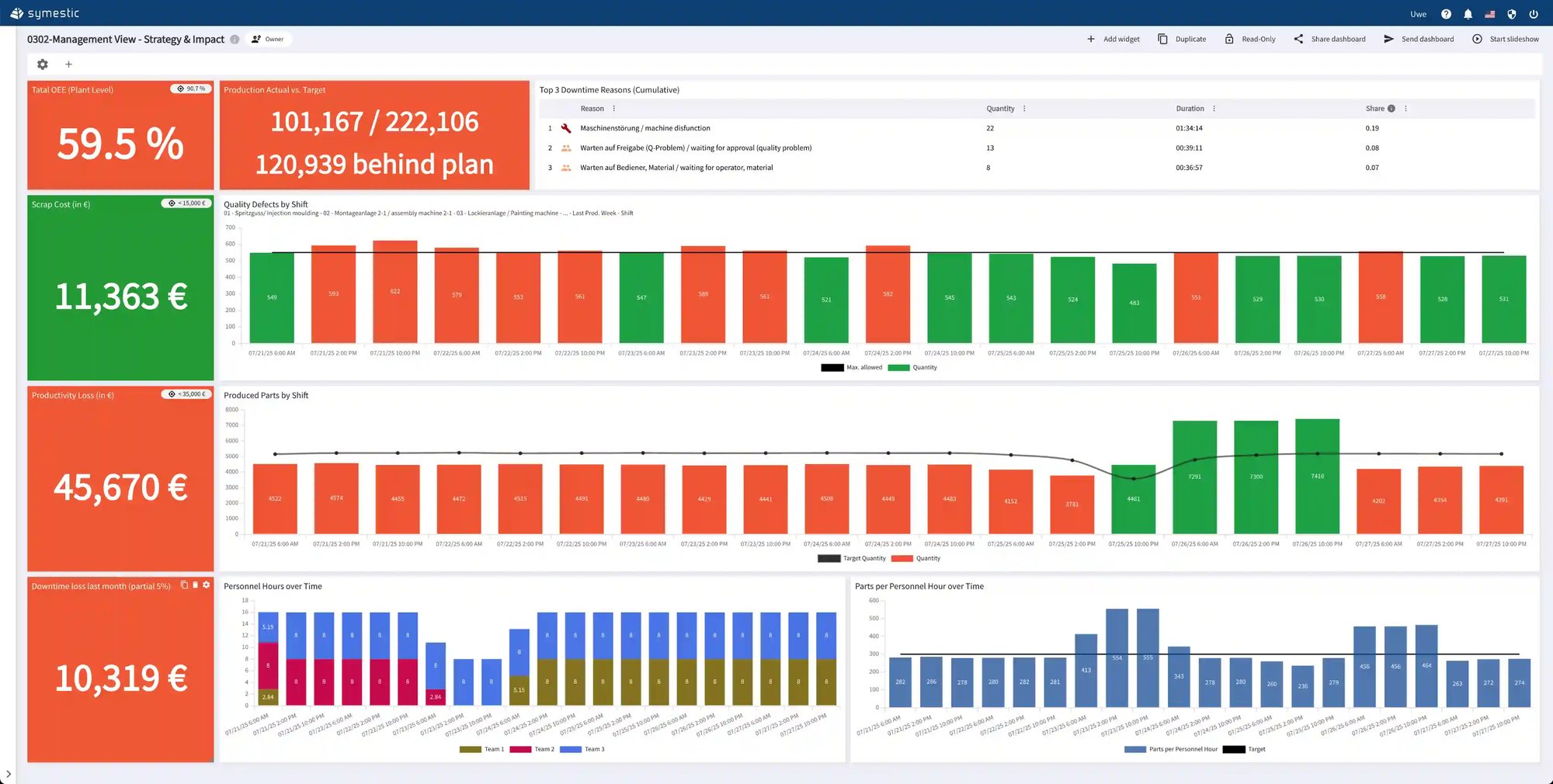

A modern digital lean manufacturing system uses live production insights to stabilize workflows, expose bottlenecks and accelerate continuous improvement.

Manufacturers that combine lean with real-time data achieve 25–40% more sustainable productivity gains compared to manual lean implementation.

Digital lean ensures consistency, speed and measurable impact across every shift.

SYMESTIC as a Complete Lean Manufacturing System

SYMESTIC integrates all essential lean functions into a single cloud-based platform.

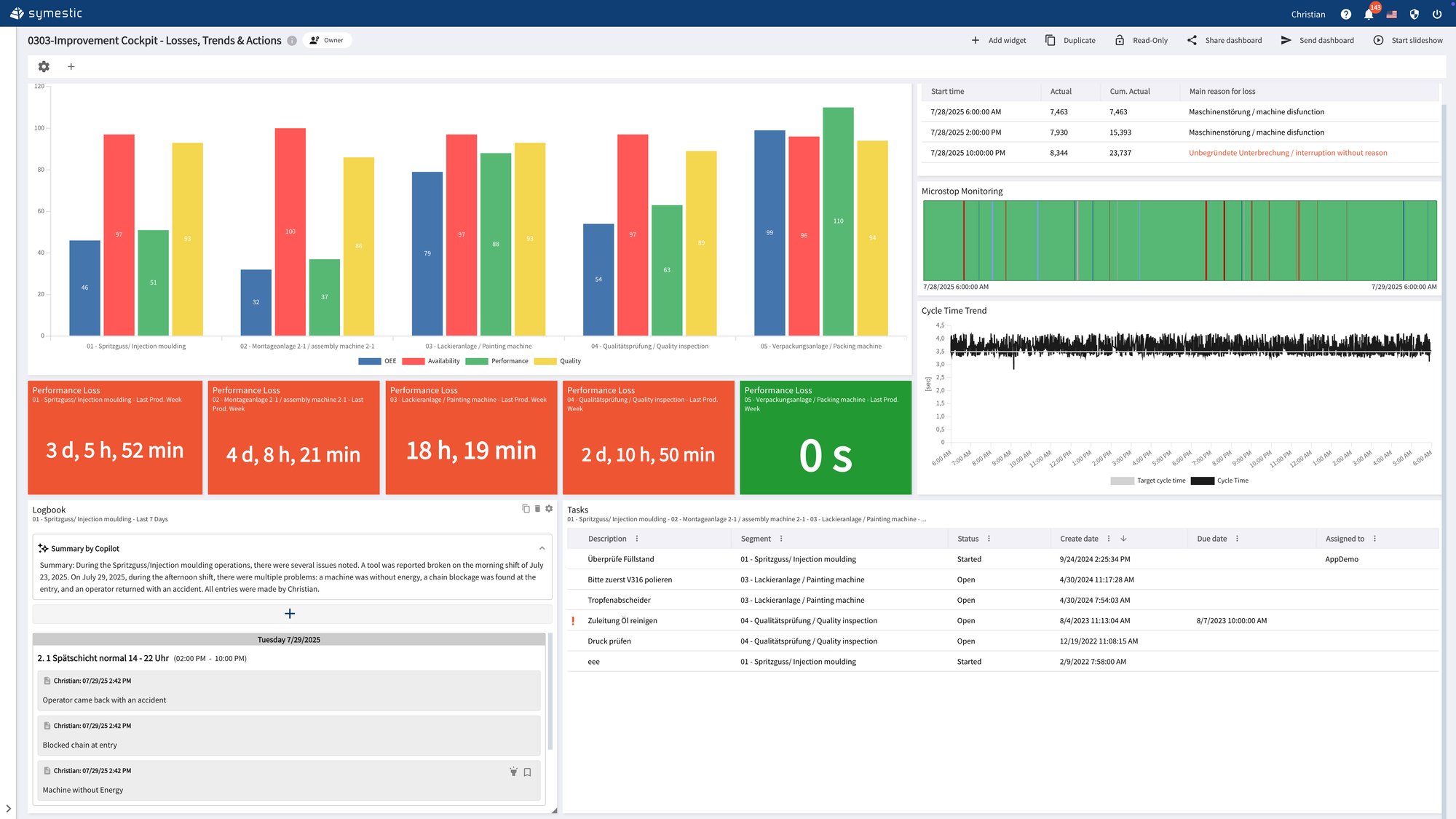

Instead of managing Kanban cards, Poka Yoke steps or improvement tasks manually, teams work with automated signals, digital workflows and real-time data — increasing accuracy and reducing reaction time.

Just-in-Time operations become transparent through live material flow insights and automated Kanban triggers.

Poka Yoke is supported by digital work instructions, in-process quality checks and automated interlocks for critical deviations.

Continuous improvement is strengthened through digital boards, structured problem-solving and end-to-end tracking of actions and results.

The result is a scalable lean system that works reliably across all plants and processes.

Lean Manufacturing Productive Within Hours

SYMESTIC enables lean execution without long IT projects.

Its cloud-native architecture allows fast onboarding and step-by-step lean rollout while delivering immediate results.

Teams use mobile tools, real-time KPIs and digital standard work to stabilize performance.

Waste hotspots become visible instantly, improvement actions gain traction and OEE can be monitored continuously as a core lean KPI.

Lean manufacturing turns into a living, measurable operating system rather than a theoretical framework.