Machine Data Collection (MDA / MDC): Real-Time Machine Data Acquisition and Visualization

Machine data collection (MDA/MDC) turns raw machine signals into real-time, actionable insights. The cloud-native SYMESTIC platform captures all machine states, cycle data, downtimes, quantities, and process values fully automatically — without operator input, terminals, or local IT.

Manufacturers gain instant transparency across their entire shopfloor and can improve performance from day one.

Why Machine Data Collection Matters

Modern production requires continuous visibility into machine performance, disturbances, and process behavior. Manual data entry is slow and inconsistent, while isolated monitoring tools often capture only fragments of the actual process.

Without real-time MDA/MDC, efficiency losses remain hidden, root causes are unclear, and decisions rely on outdated or incomplete information.

MDA ensures that all relevant data — states, stop reasons, cycle times, scrap indicators, energy usage — is captured automatically and becomes immediately usable for operations, engineering, and management.

How SYMESTIC Collects Machine Data Automatically

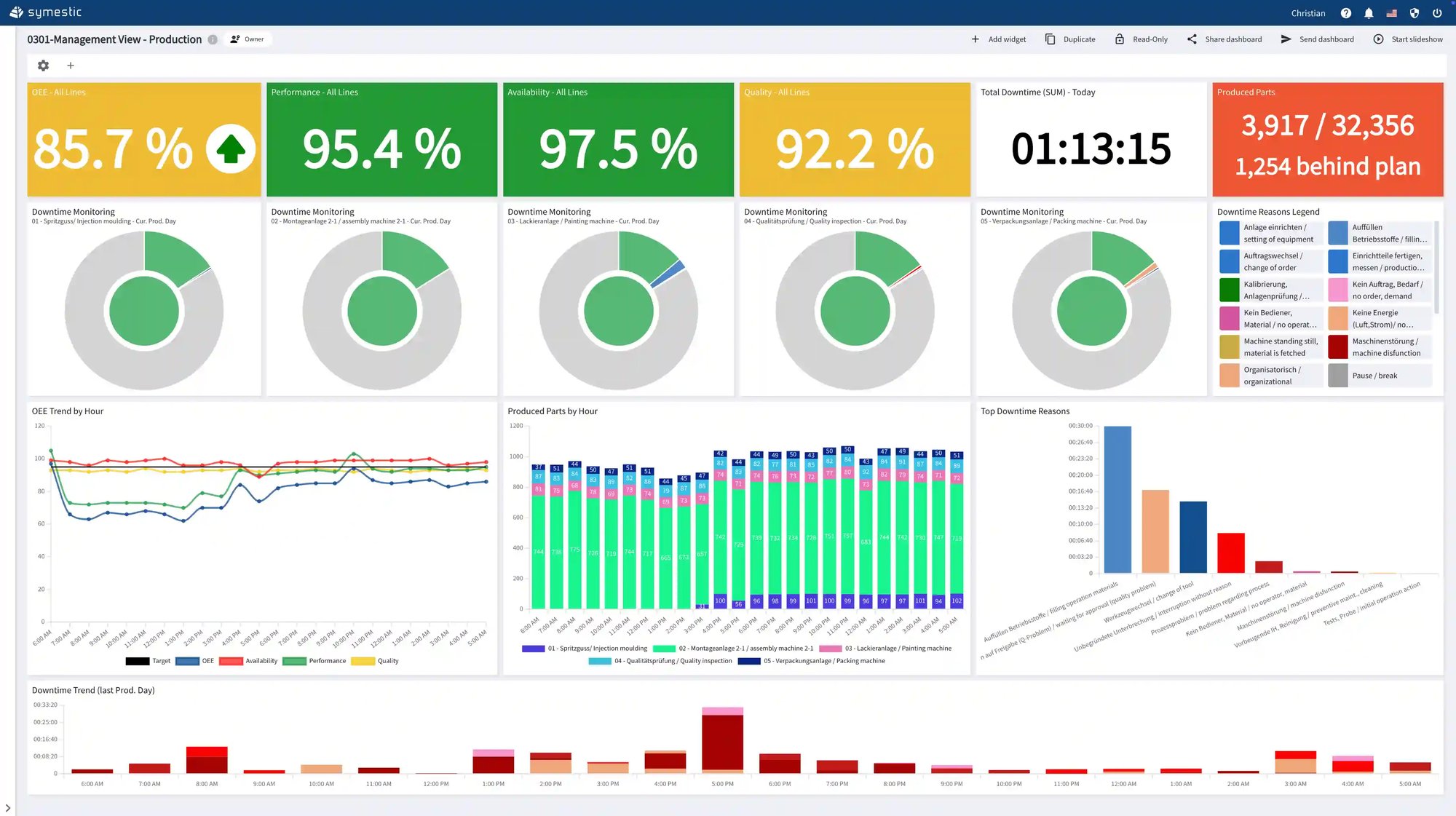

SYMESTIC connects seamlessly to PLCs, sensors, robots, CNC machines, and legacy equipment. Machine data is acquired continuously, normalized, and displayed in intuitive dashboards.

Teams see performance at a glance and detect anomalies early, long before they escalate into downtime or scrap.

Machine states, cycle counts, stop reasons, and process parameters are logged with precise timestamps. Quality-relevant values can be captured directly from measurement devices. All information becomes available in real time — across shifts, lines, and locations.

Real-Time Visualization for Fast, Clear Insight

SYMESTIC transforms machine data into meaningful visualizations:

current status per machine, order progress, performance trends, cycle-time stability, loss patterns, and downtime classification.

Dashboards are designed for daily production meetings, team briefings, and management reporting.

Deviations trigger immediate alerts so teams can respond before major losses occur.

Reduce Downtime Through Accurate MDA/MDC

Machine stops are captured automatically, with precise timestamps and context.

SYMESTIC classifies disturbances, highlights recurring patterns, and reveals the true root causes of performance losses.

Teams can act faster, avoid repeated failures, and stabilize throughput even in high-speed environments.

Retrofit Machine Data Collection for Any Machine Fleet

SYMESTIC supports all machine types — new or old.

Legacy machines can be retrofitted easily via sensor-based data capture.

No changes to machine control are required.

Companies can start small and expand MDA step-by-step, from a single station to entire production lines.

MDA Data as the Foundation for All SYMESTIC Modules

All automatically collected machine data feeds directly into the full SYMESTIC ecosystem:

Production KPIs, OEE dashboards, alarms, process monitoring, production control, and planning tools all rely on the same unified data layer.

This ensures consistent reporting and a single source of truth across the entire factory.