Manufacturing Software

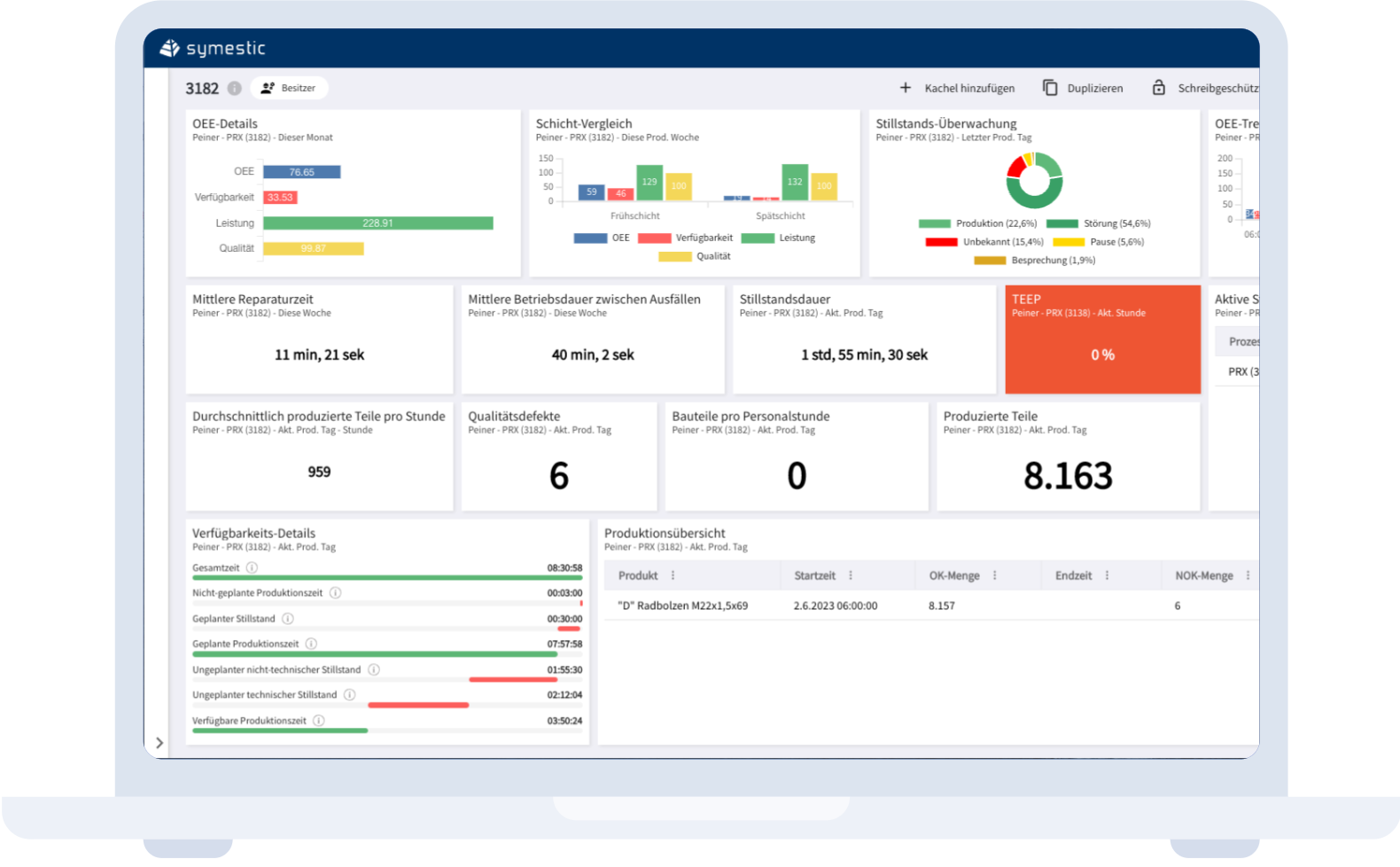

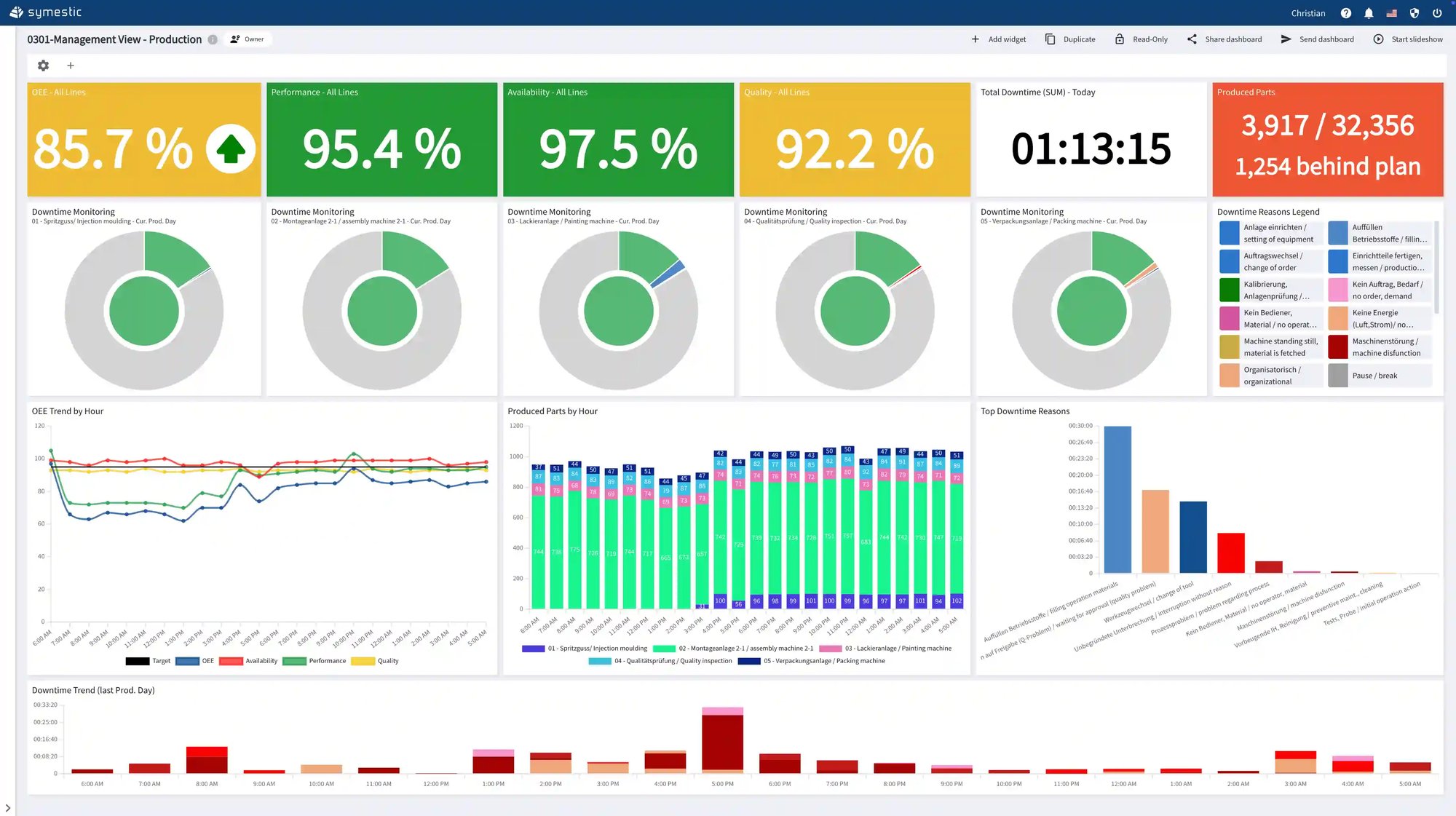

Manufacturing software from SYMESTIC digitizes your entire production environment with integrated cloud modules for production control, data acquisition, and real-time KPI tracking.

One unified platform for all manufacturing requirements — from planning and scheduling to execution, quality, and continuous improvement.

If you are looking for more MES fundamentals, you can find our main article here: MES – explained simply.

Challenges of Isolated Standalone Tools

Software silos and fragmented data flows

- Different systems without seamless data exchange

- Manual transfer between tools and spreadsheets

- Inconsistent data quality and availability

- High maintenance effort across multiple systems

Lack of end-to-end visibility

- Production status only available in fragments

- Difficult coordination across production areas

- No unified data basis for decision-making

- Complex integrations when adding new functionality

SYMESTIC: Integrated Cloud Manufacturing Software

All modules in one platform

- Digital production control for streamlined order execution

- Advanced production planning for optimal resource utilization

- Automated OEE and performance KPIs

- Continuous process data monitoring

- Real-time alarm management

Cloud-native with zero IT effort

- Go live in 3 hours without IT specialists

- Automatic updates and maintenance included

- Scales from a single machine to multi-site operations

- Mobile access for all user groups

Retrofit-ready for any machine

- Connect machines of all ages without hardware replacement

- Standard interfaces for common controllers

- Sensor-based solutions for legacy equipment

- Expand step by step — line by line, plant by plant

Instantly Productive Manufacturing Software

SYMESTIC Manufacturing Software becomes productive immediately — without long projects:- Trusted by more than 100 companies

- Average 20% productivity increase within the first year

- ROI typically achieved in 3–6 months

- Continuous feature expansion at no additional cost