MES for Contract Manufacturing

MES for contract manufacturing from SYMESTIC masters the complexity of highly individualized production.

You benefit from flexible order processing, transparent project control, and precise resource planning.

Every customer-specific order is digitally supported from request to delivery.

Challenges in Contract Manufacturing

Individual customer requirements

- Every order has unique specifications

- Adaptation to changing product requirements

- Customer-specific quality checks and test procedures

- Documentation and traceability of every custom step

Complex project coordination

- Coordination of multiple production steps and departments

- On-time delivery despite unpredictable events

- Resource planning for fluctuating order volumes

- Real-time transparency for customers and management

Why SYMESTIC Is Ideal for Contract Manufacturing

Flexible production control

- Digital workflow from request to shipment

- Custom routings and work plans for each order

- Real-time status of all active projects

- Customer-specific documentation and reporting

Intelligent finite scheduling

- Optimal allocation of resources for varying order sizes

- Staff and machine planning for single-item production

- Bottleneck management for critical resources

- High delivery reliability through precise algorithms

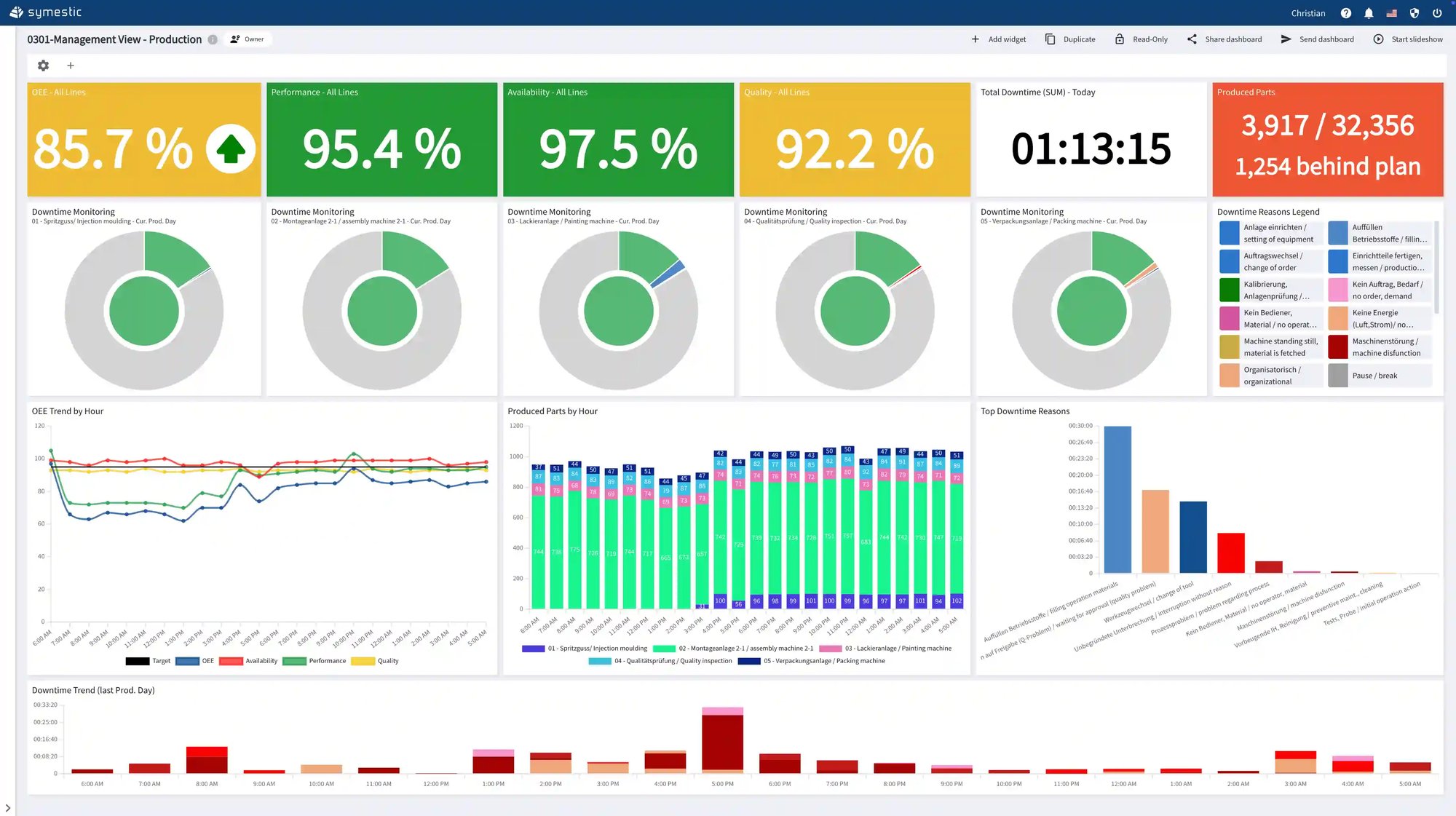

Transparent production KPIs

- OEE tracking that even works for one-off orders

- Job-based efficiency analytics

- Cost transparency per project

- Post-calculation & improvement insights

Proven SYMESTIC Modules for Contract Manufacturing

Order-optimized modules:

- Production Control: Complete digital order execution

- Finite Scheduling: Flexible resource planning for custom jobs

- Production KPIs: Efficiency tracking per order

- Alarms: Instant notifications for delays

- Process Data: Customer-specific parameter documentation