MES for Food & Beverage

The MES for Food & Beverage from SYMESTIC meets the strict requirements of the food industry through complete batch traceability, continuous process monitoring, and HACCP-compliant documentation.

Proven at ADM, Stroetmann, and Erlenbacher — backed by more than 20 years of automation expertise.

Food-Industry Challenges Mastered

Food quality and safety

- Meet strict regulations and industry standards

- Full traceability from raw ingredients to finished product

- HACCP-compliant documentation of all production steps

- Immediate response to quality deviations

High perishability

- Continuous monitoring from storage to packaging

- Tight control of temperature and shelf-life

- Maintain freshness and quality throughout production

- Minimize product losses caused by spoilage

Complex supply chains

- Ingredients sourced from multiple regions and countries

- Coordination across storage, production, and packaging

- Supplier quality and safety verification

- Logistics planning under tight shelf-life constraints

Food-Specific SYMESTIC Modules

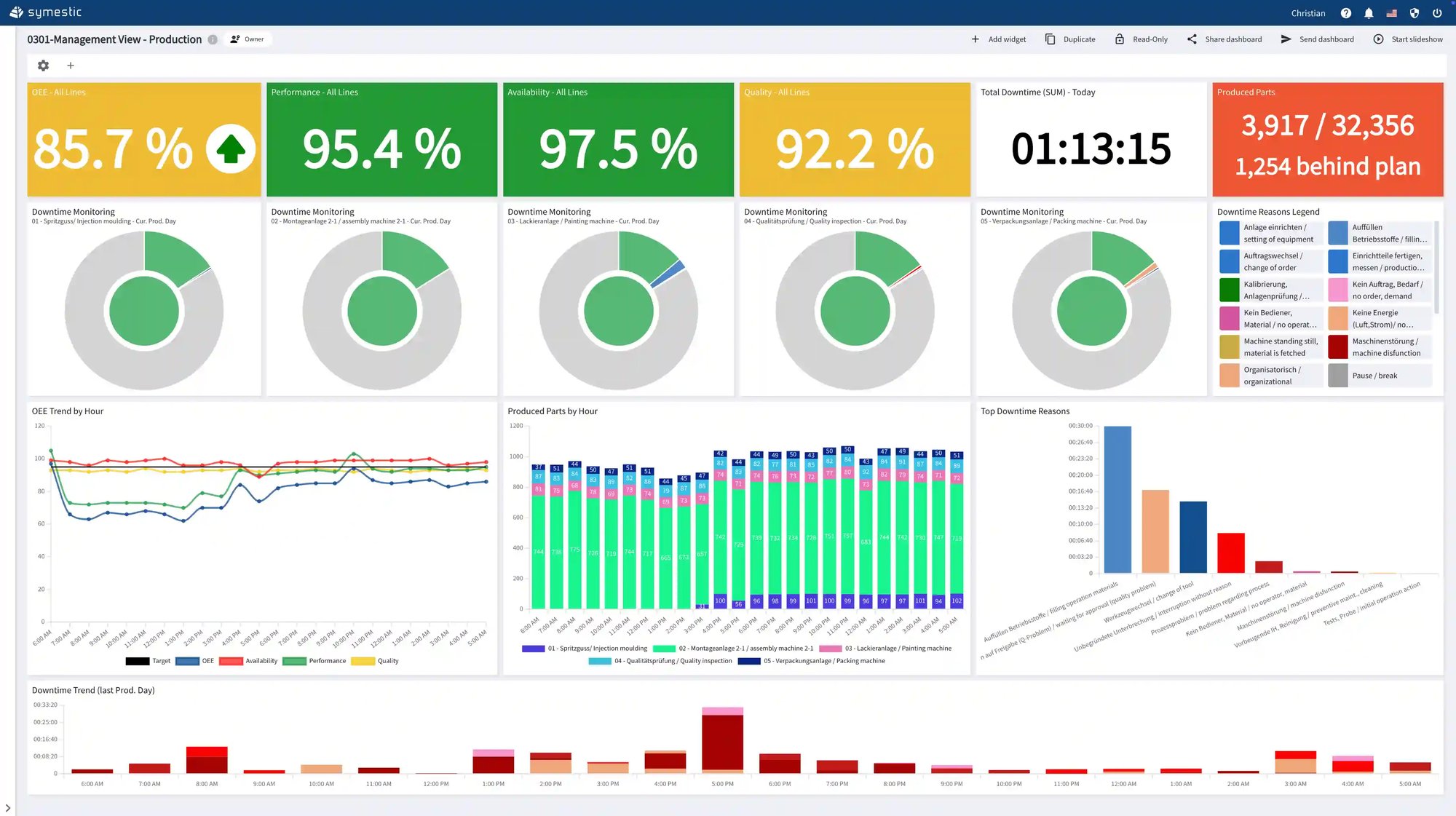

SYMESTIC offers modules tailored specifically to the needs of food and beverage manufacturers. Continuous monitoring of critical production parameters such as temperature or pH value ensures process stability, while OEE tracking for filling and packaging lines uncovers efficiency losses and supports continuous improvement.

Digital batch management provides complete documentation from raw materials to finished goods. Automated alarms highlight food-safety-relevant deviations instantly, and advanced planning optimizes production sequences by incorporating shelf-life constraints, resource availability, and quality priorities. These capabilities give food manufacturers a robust foundation for safe, efficient, and compliant production.

SYMESTIC: Proven Solution for Food & Beverage Manufacturers

SYMESTIC provides continuous real-time insight into all relevant process and quality parameters — from tank storage to filling and packaging. Deviations are detected the moment they occur, allowing teams to intervene early and prevent quality issues before they develop into product losses or potential safety risks.

The system automatically captures all required regulatory documentation, creating complete, audit-ready traceability and enabling rapid impact analysis in the event of recalls.

By consolidating MES, ERP, PLM and inspection systems into one unified platform, SYMESTIC ensures consistent data quality across all production stages. Even older equipment can be connected through retrofit-ready technology, making modernization simple and cost-effective.