MES for Assembly and Joining Processes

Assembly and joining are where value and risk come together. Screwing, pressing, riveting, welding, adhesive bonding and potting must hit takt, variant complexity and 0-defect targets at the same time. Rework, scrap and field returns are expensive and highly visible. A generic system that only counts OK/NOK is not enough.

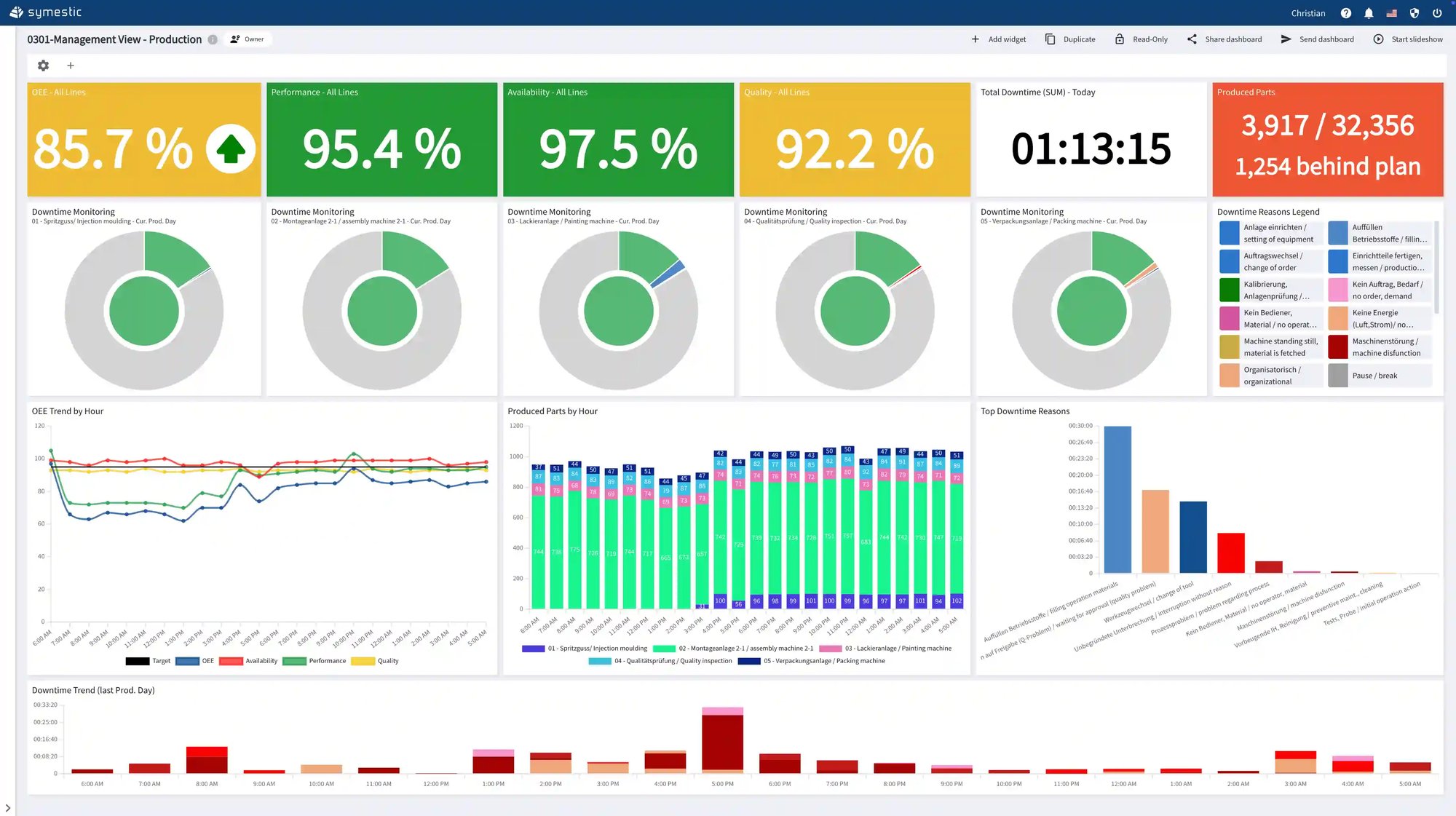

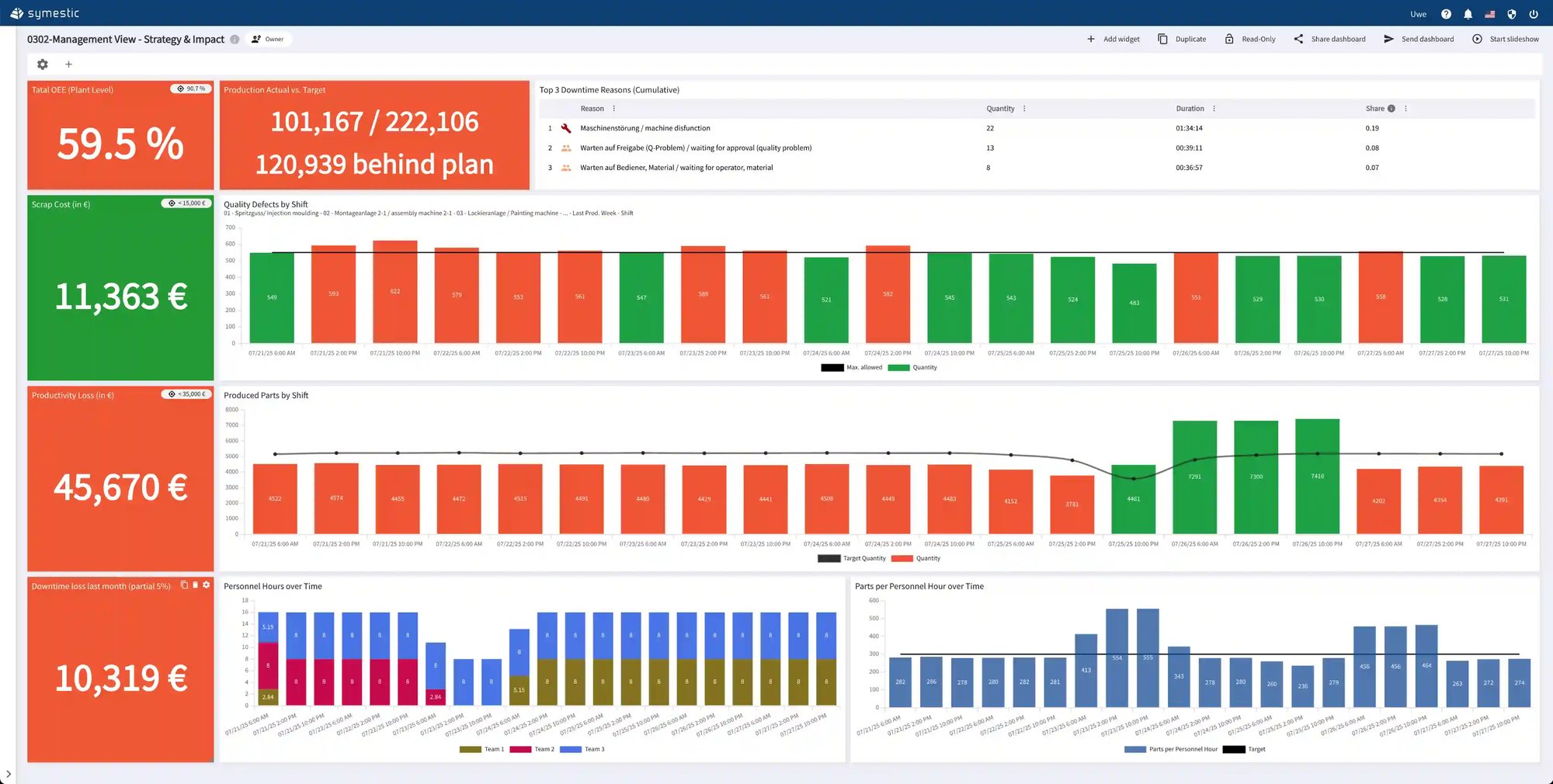

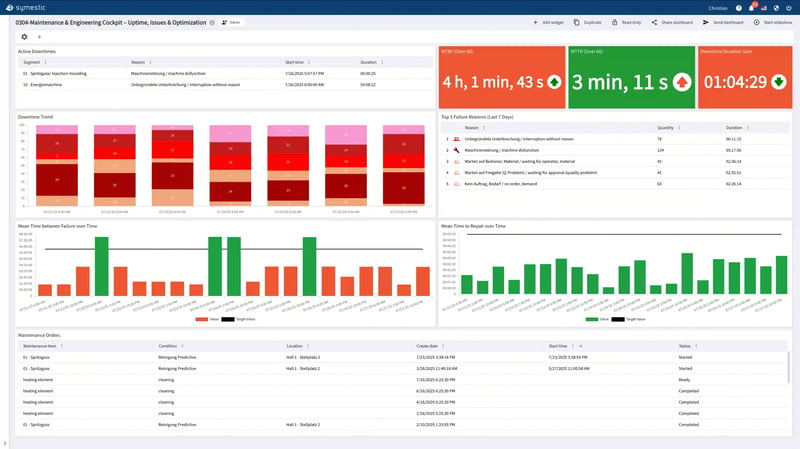

SYMESTIC is a cloud MES for assembly and joining processes that gives you full transparency from station to serial number.

Where assembly lines lose money

Many plants lack hard numbers at station level. Takt overruns, microstops, screw reworks, bypassed interlocks or missing components are underreported or hidden in local tools. Traceability is incomplete: you cannot always prove which screw curve, press curve or weld program went into which product. Variant complexity and frequent changeovers increase the risk of wrong variants, wrong parts and undocumented deviations, while customer and audit pressure grows.

How SYMESTIC Cloud MES secures assembly and joining

SYMESTIC connects screwdrivers, presses, weld cells, adhesive and potting stations, rotary tables and manual workstations to a central cloud MES. Process and quality data are captured in real time and evaluated per station, variant, order and serial number. OEE is visible not only per line but per workplace. Workers are guided with digital work instructions, checklists and Poka Yoke logic, while screw results, press curves, IO/NIO decisions and rework loops are tied to each serial number.

Use cases: screw, press, weld and adhesive processes

In screw assemblies, SYMESTIC records torque/angle results, NIO attempts and overrides, and links them to variants and tightening programs. Wrong or missing screws are drastically reduced. In press and insertion processes, force/stroke curves and limits are monitored so incomplete or misaligned press fits are caught immediately. In welding, adhesive and potting processes, programs, parameter windows and, where available, vision checks are linked to serial numbers, which cuts rework and end-of-line inspection effort and strengthens audit readiness.

Next step: pilot on a critical assembly line

If your assembly and joining processes are still steered with shift notes, isolated tools and late Excel reports, a focused pilot is the logical next step. We select a key line or rotary system, define targets for OEE, rework, traceability and complaints and bring SYMESTIC Cloud MES live in a short timeframe. You see on your own assembly lines how real-time transparency and digital worker guidance impact quality and throughput before you roll the solution out to further lines and plants.