MES for Batch and Semi-Continuous Processes

Batch and semi-continuous processes like mixing, dosing, heating/cooling, coating and reactions are sensitive and expensive. Raw materials and energy are costly, specs are narrow and audit pressure is high. Small deviations from the recipe window quickly create off-spec batches.

SYMESTIC is a cloud MES for batch manufacturing and process industries that connects planning, execution and electronic batch records in one system.

Pain points in batch and process manufacturing

Many plants run with a mix of PLC logic, stand-alone recipe tools, paper batch sheets and Excel planning. Batch protocols are incomplete or inconsistent. Deviations in time, temperature, dosing or agitation are noticed too late.

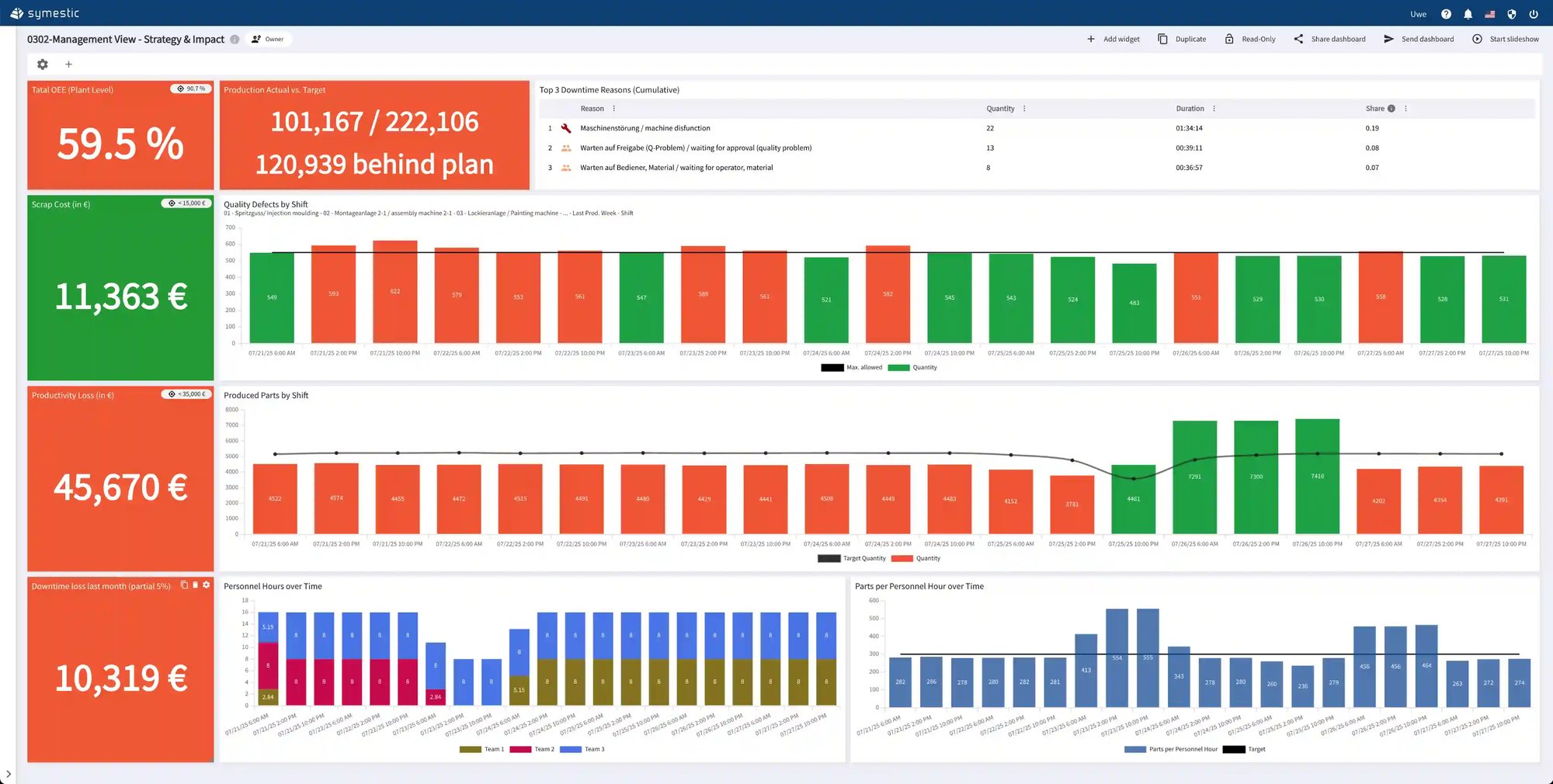

Root causes for quality issues remain unclear, while documentation and audit preparation consume a lot of manual effort. Energy and capacity cannot be optimized because losses from stops, restarts and off-spec batches are not quantified.

How SYMESTIC Cloud MES stabilizes batch processes

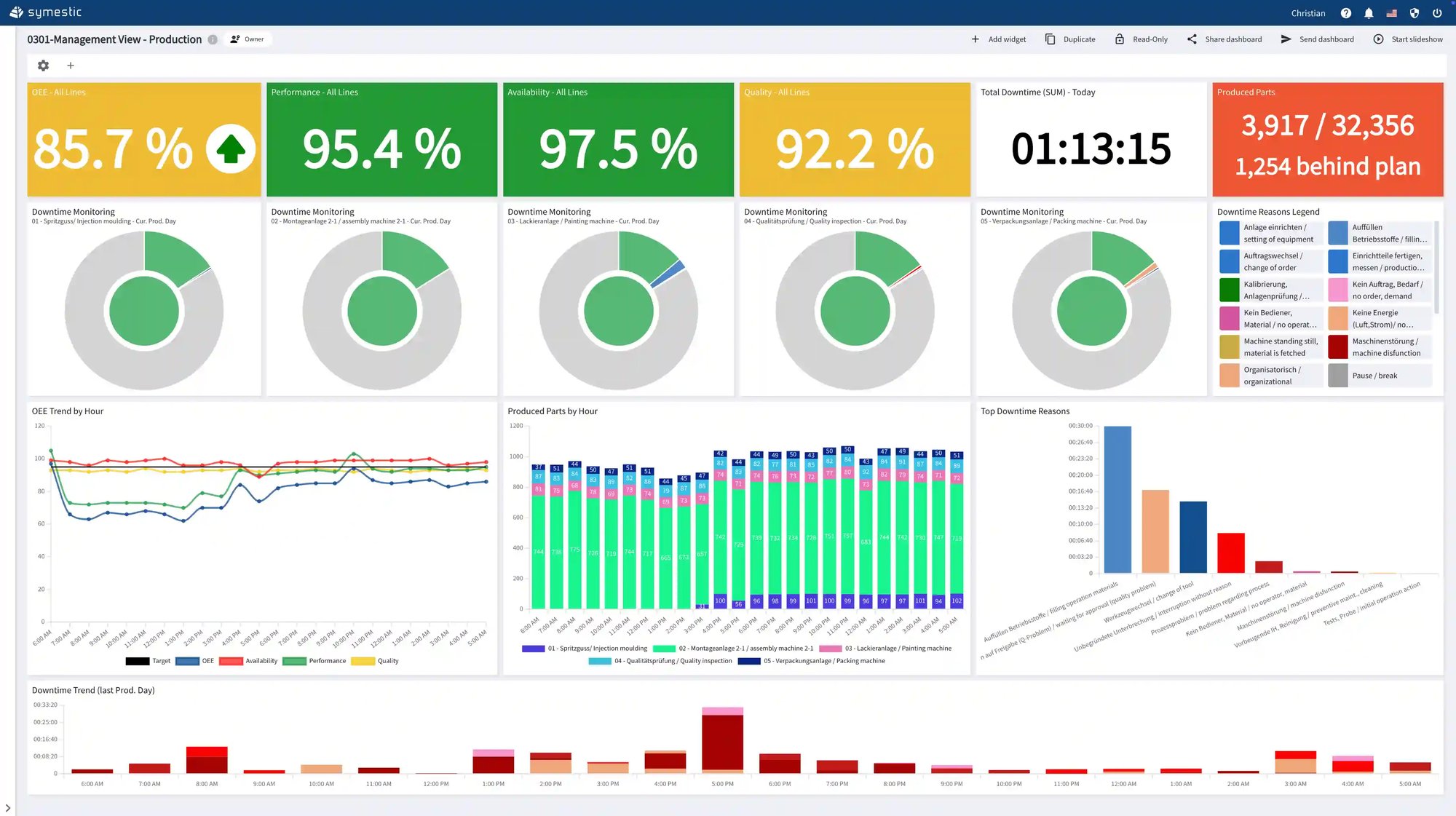

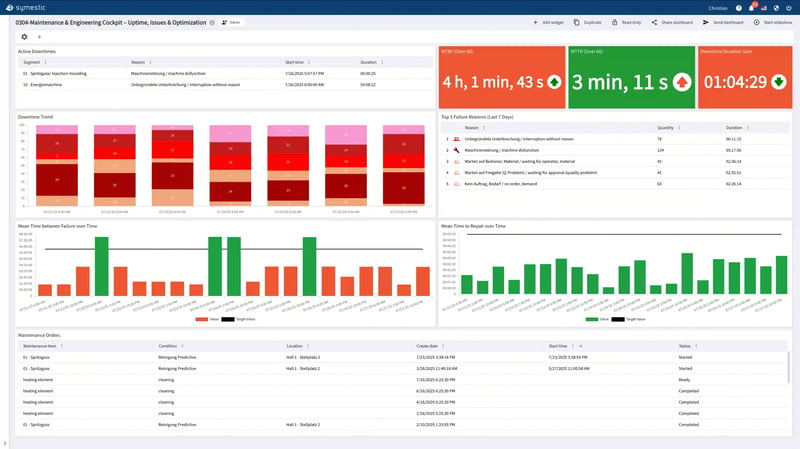

SYMESTIC links mixers, reactors, coating lines, dosing skids and auxiliary systems into a central cloud MES. Process data and quality events are captured in real time and evaluated per batch, recipe, line and asset. Critical parameters such as time, temperature, speed, flow and pressure are monitored against targets and limits.

The OEE of your batch assets becomes visible, including losses from availability, speed and quality. Planning, approvals, weighing, start/stop logic and in-process checks can be digitally guided so you build consistent electronic batch records without extra paperwork.

Use cases: mixing, coating and reaction processes

In mixing and dosing, SYMESTIC keeps track of which materials and lots went into which batch, with actual quantities, corrections and rework attempts. Underdosing, overdosing and repeated batches become visible and can be linked to quality and yield. In coating and curing, times, temperatures and layer counts are monitored so unstable process windows are detected early.

In reaction and fermentation processes, parameter profiles and alarms are tied to batch approvals, so deviations are caught before entire batches go off spec.

Next step: pilot SYMESTIC in a batch area

If you want to move away from paper batch records, isolated recipe tools and manual audit preparation, a focused pilot is the logical starting point. Together we choose a representative batch line or product family, set goals for OEE, scrap, documentation effort and audit readiness and bring SYMESTIC Cloud MES live in a short timeframe.

You see on your own mixers, reactors and coating lines how real-time transparency and digital batch documentation impact quality, yield and compliance.