MES for Forming and Molding Processes

In forming and molding, every minute hits your margin: expensive tools, long changeovers, high scrap risk. Injection molding, die casting, stamping, deep drawing and bending are extremely sensitive to small process shifts. Without objective data, OEE, scrap and tool availability become guesswork.

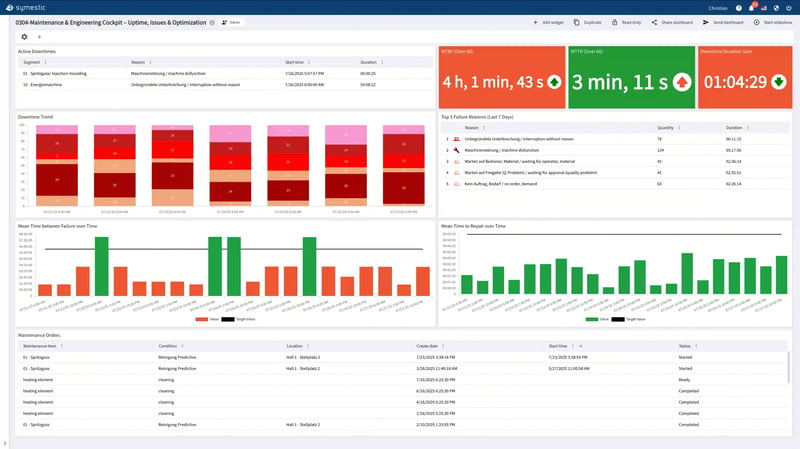

SYMESTIC is a cloud-native manufacturing execution system (MES) for forming and molding processes that makes performance and losses measurable in real time.

Typical issues in forming and molding lines

Most plants only see aggregate output and scrap. They do not see which tools, cavities, materials or shifts are driving downtime and losses. Microstops, ramp-up scrap, cavity problems, tool wear or temperature issues are either not captured at all or buried in local systems. Planning, production and quality work with different numbers, while delivery pressure and cost pressure increase.

How SYMESTIC Cloud MES makes forming and molding transparent

SYMESTIC connects injection molding machines, die casting cells, presses, stamping and bending lines to a central cloud MES. Machine states, cycles, tool changes, alarms and quality events are captured in real time and evaluated per order, tool, cavity, machine and material lot. OEE is broken down into availability, performance and quality losses, with clear root-cause categories. Operators and supervisors see immediately when cycle times drift, scrap spikes after a changeover or specific tools repeatedly cause unplanned stops.

Next step: pilot SYMESTIC on a forming line

If you want to stop running forming and molding in the dark, the next step is a focused pilot. Together we pick a representative forming area, define clear goals for OEE, scrap and tool downtime and bring SYMESTIC Cloud MES live in weeks, not months. You see on your own injection molding, die casting and stamping lines how real-time transparency translates into higher throughput and lower scrap, before scaling across plants.

Meta (Forming & Molding):

Cloud MES for forming and molding: boost OEE, cut scrap and tool downtime across injection molding, die casting and stamping lines.