MES for High-Mix Manufacturing

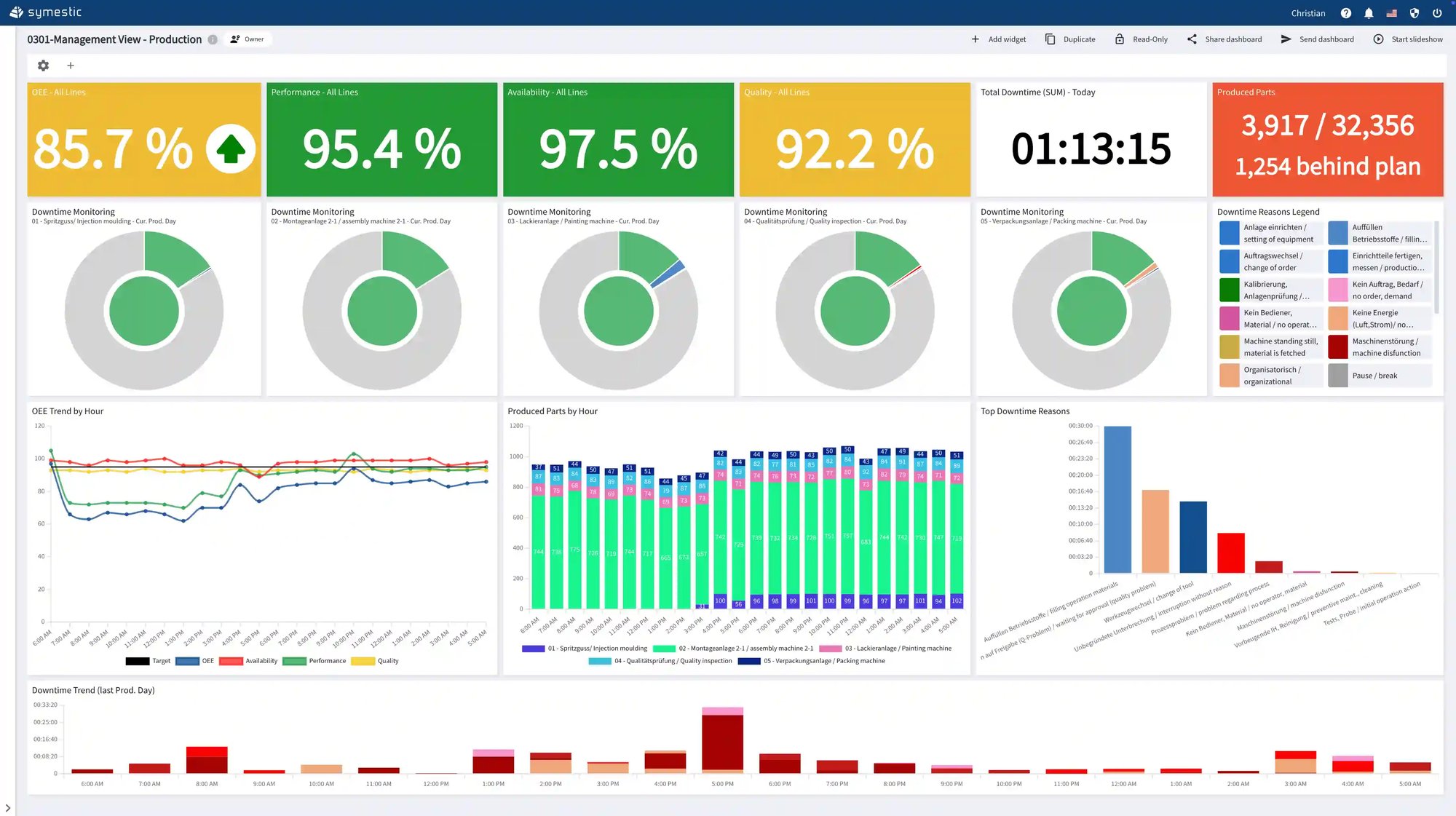

The MES for High-Mix Manufacturing from SYMESTIC enables fast, error-free production across a large number of variants. The system supports frequent changeovers with standardized setup processes, digital work instructions, and real-time transparency across all orders – even when specifications change daily.

With automated documentation, integrated quality control, and continuous process monitoring, production stays stable and efficient, regardless of product complexity.

Challenges in High-Mix Production

Manufacturers with high product variability must handle constant changeovers, fluctuating bill-of-materials, and variant-specific quality requirements. Frequent switches between product versions increase the risk of setup errors, missing components, wrong parameters, and rising scrap. Delivery reliability becomes difficult when planning, production, and quality work with incomplete or outdated information.

Without digital control, teams lose valuable time coordinating changes manually, dealing with miscommunication, and resolving errors that arise from inconsistent variant data.

SYMESTIC: Built for Variant-Rich Manufacturing

SYMESTIC provides a cloud-native MES that standardizes setup processes, guides operators with variant-specific work instructions, and automatically applies the correct parameters for each version. This reduces errors, stabilizes workflows, and ensures consistent quality even with high mix and low volumes.

Real-time process monitoring detects deviations immediately, while digital documentation ensures full traceability for every variant. Integrated advanced planning optimizes production sequences based on setup times, resource availability, and delivery priorities — resulting in fewer changeovers, shorter downtimes, and more predictable performance.

Proven SYMESTIC Modules for Variant Production

SYMESTIC combines production execution, advanced planning, process-data monitoring, alarms, and full traceability into one platform. Each variant is clearly documented, every step is traceable, and all quality-critical parameters are captured automatically.

This gives high-mix manufacturers the control they need to manage complexity, avoid errors, and maintain stable, efficient production at scale.