MES for Machining and CNC Manufacturing

Machining and CNC operations tie up capital in expensive equipment and tooling. At the same time, order volatility, small batches and tight tolerances are rising. Without a clear view of runtime, setup, microstops, tool events and quality, your CNC area runs below its true potential.

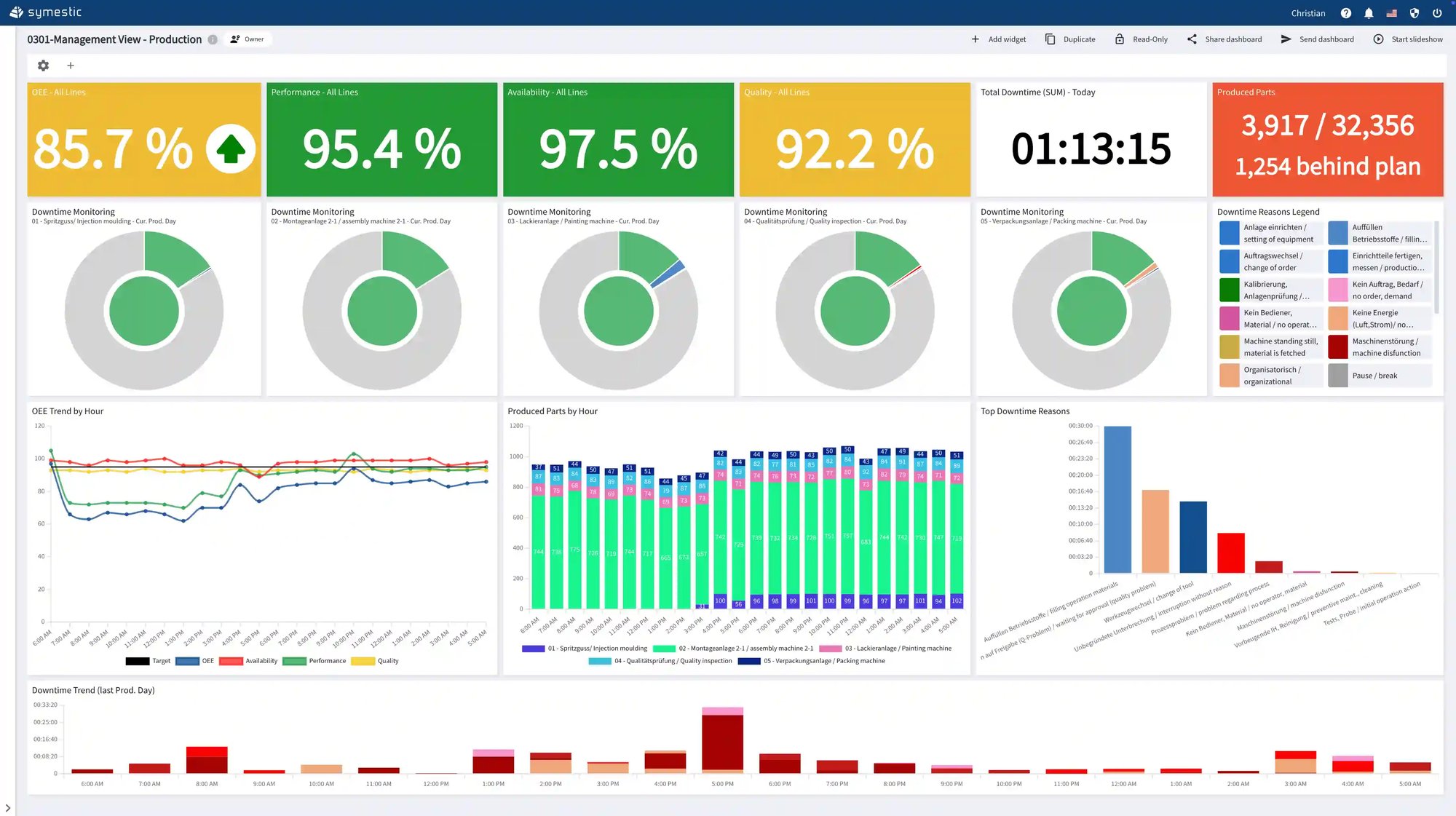

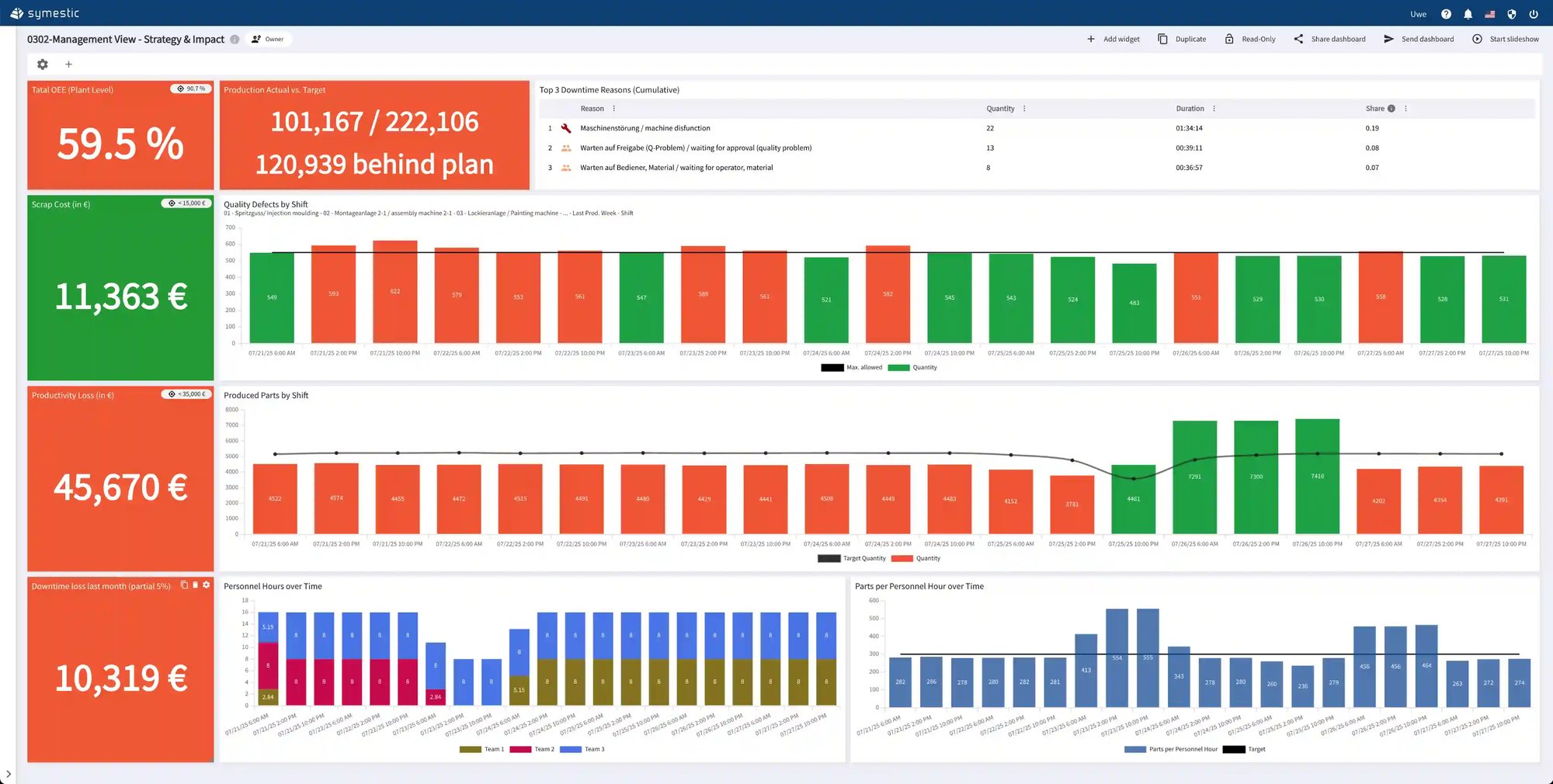

SYMESTIC is a cloud MES for machining and CNC manufacturing that makes machine performance, tool usage and quality losses transparent in real time.

Hidden losses in machining and CNC areas

Many machine shops have abundant data in the controls, but little consolidated insight. OEE, setup time, tool-related downtime and scrap are tracked late and manually. Constraints move between machines without being visible. Tool and fixture costs grow, but nobody can clearly link them to specific parts, programs or strategies. Planning only sees quantities and due dates, not the real performance of individual machines and shifts.

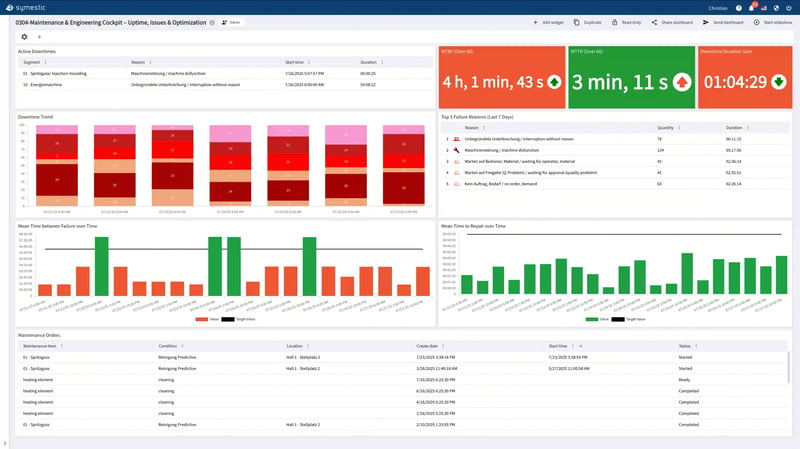

How SYMESTIC Cloud MES makes CNC performance measurable

SYMESTIC connects CNC machines, machining centers, grinders and sheet metal equipment to a central cloud MES. Machine states, programs, cycle and secondary times, alarms and quality events are collected and evaluated per order, part, tool, machine and shift. OEE is available on machine, line and area level, split into availability, performance and quality. Setup and secondary time are cleanly separated from cutting time so you see which products and programs drive non-value-adding time and where setup concepts must be improved.

Use cases: CNC machining and sheet metal fabrication

In CNC machining, SYMESTIC shows machine runtime, program changes, microstops, tool changes and scrap patterns per part and program. You can tell which combinations of tool, strategy and program are robust and where unplanned stops and rework accumulate. In sheet metal (laser cutting, punching, bending), the system helps you manage throughput across linked processes, expose bottlenecks between cutting and forming and tie rework and quality issues back to machines, programs and material lots.

Next step: pilot in your machining area

If you are still steering machining and CNC based on gut feel, isolated reports and shift notes, a focused pilot is the next logical move. We select a representative CNC or sheet metal area, define clear goals for OEE, setup and secondary time and scrap and bring SYMESTIC Cloud MES live quickly. You see on your own machines and programs how real-time transparency and structured OEE reporting improve productivity, on-time delivery and tool economics before scaling out.