MES for Material Flow and Intralogistics

Material flow and intralogistics determine whether your lines actually run. Conveyor systems, pallet and carrier systems, supermarkets, tugger trains and AGV/AMR fleets must deliver the right material to the right place at the right time. If flows, buffers and routes are not transparent, material becomes the hidden bottleneck.

SYMESTIC is a cloud MES for material flow and intralogistics that makes internal logistics measurable and steerable.

Typical issues in material flow and intralogistics

In many plants, nobody has a real-time view of where material is, which buffers are full or empty and why lines are waiting. WT jams, missing carriers, misrouted parts, empty bins and unclear priorities cause waiting time at bottleneck machines while other areas stand idle. Transport orders are managed via phone, paper or simple scans. AGV/AMR fleets run suboptimally because priorities and routes are not synchronized with live production needs.

How SYMESTIC Cloud MES makes internal logistics visible

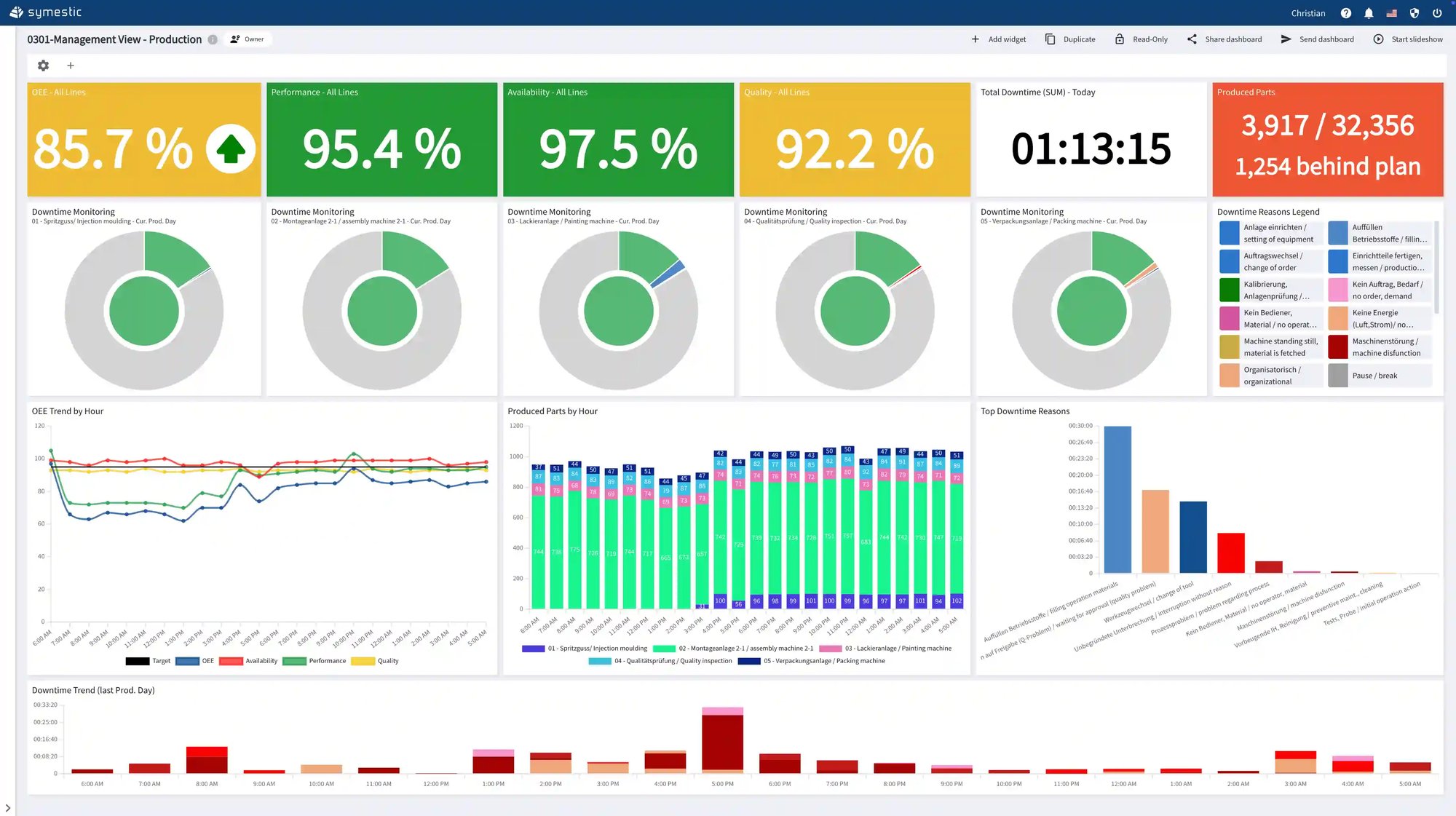

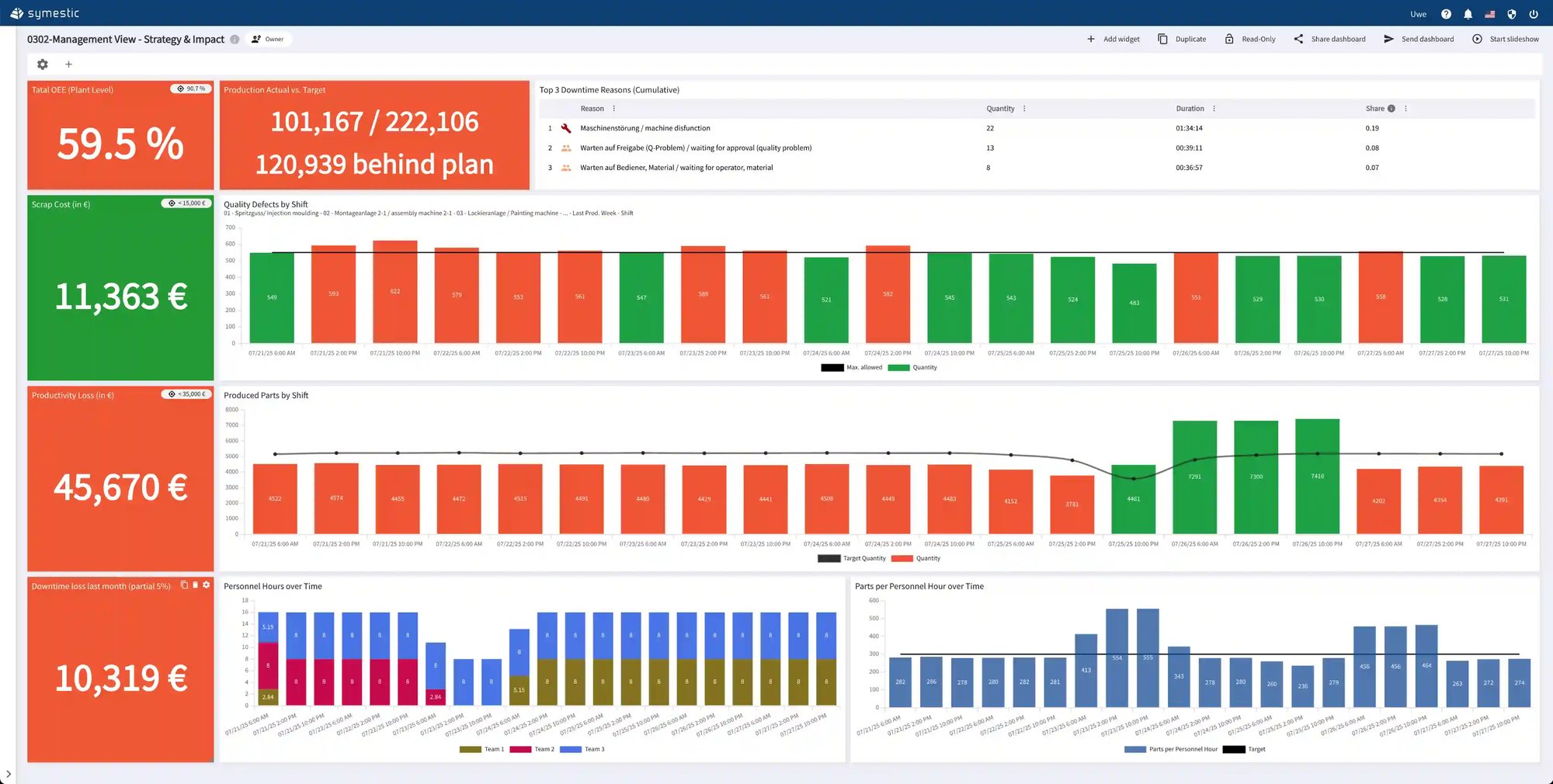

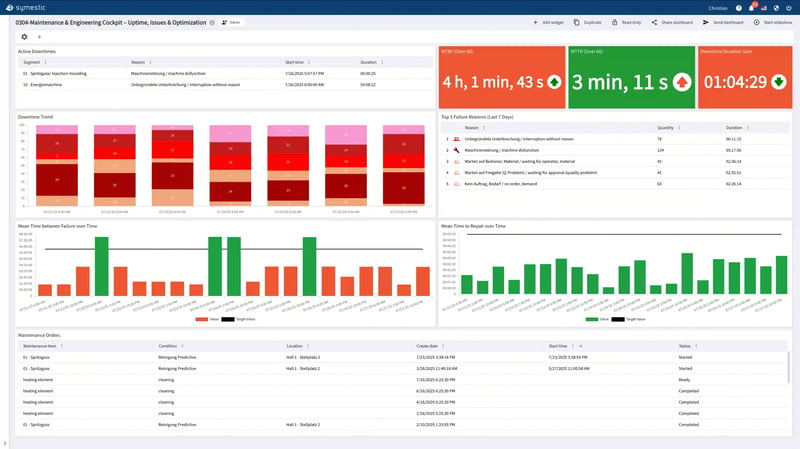

SYMESTIC connects conveyors, carrier systems, buffers, supermarkets, tugger trains and AGV/AMR fleets to a central cloud MES. Movements are captured via barcode, RFID or vision and linked to orders, serial numbers, bins and carriers. You see in real time which material is where, which buffers are over- or underutilized and where flow breaks occur. OEE for linked lines includes material-related losses such as waiting for material, buffer blockages and missing containers as their own loss categories.

Use cases: conveyors, carrier systems and AGV/AMR

In conveyor and WT systems, SYMESTIC highlights segments and buffers that regularly cause jams or backlogs and shows how this impacts throughput and takt stability. In AGV/AMR-based flows, transport orders, routes and destinations are linked to live production demand so fleets can be optimized by data rather than static rules.

In supermarket and Kanban concepts, the system tracks bin flows and replenishment signals, so shortages and overstock become transparent and controllable.

Next step: pilot on a key material flow

If your internal logistics is still steered by experience, local displays and ad hoc communication, a focused pilot is the right starting point. Together we choose a linked line or key logistics area, define goals for throughput, waiting time and steering effort and bring SYMESTIC Cloud MES live quickly.

You see on your own conveyors, WT systems and AGV/AMR fleets how real-time transparency and data-driven control remove material flow as a hidden bottleneck.