MES for Test Stands and End-of-Line Testing

Test stands and end-of-line (EOL) systems decide what leaves your plant as OK, rework or scrap. They are expensive, takt-critical and highly visible to customers and auditors.

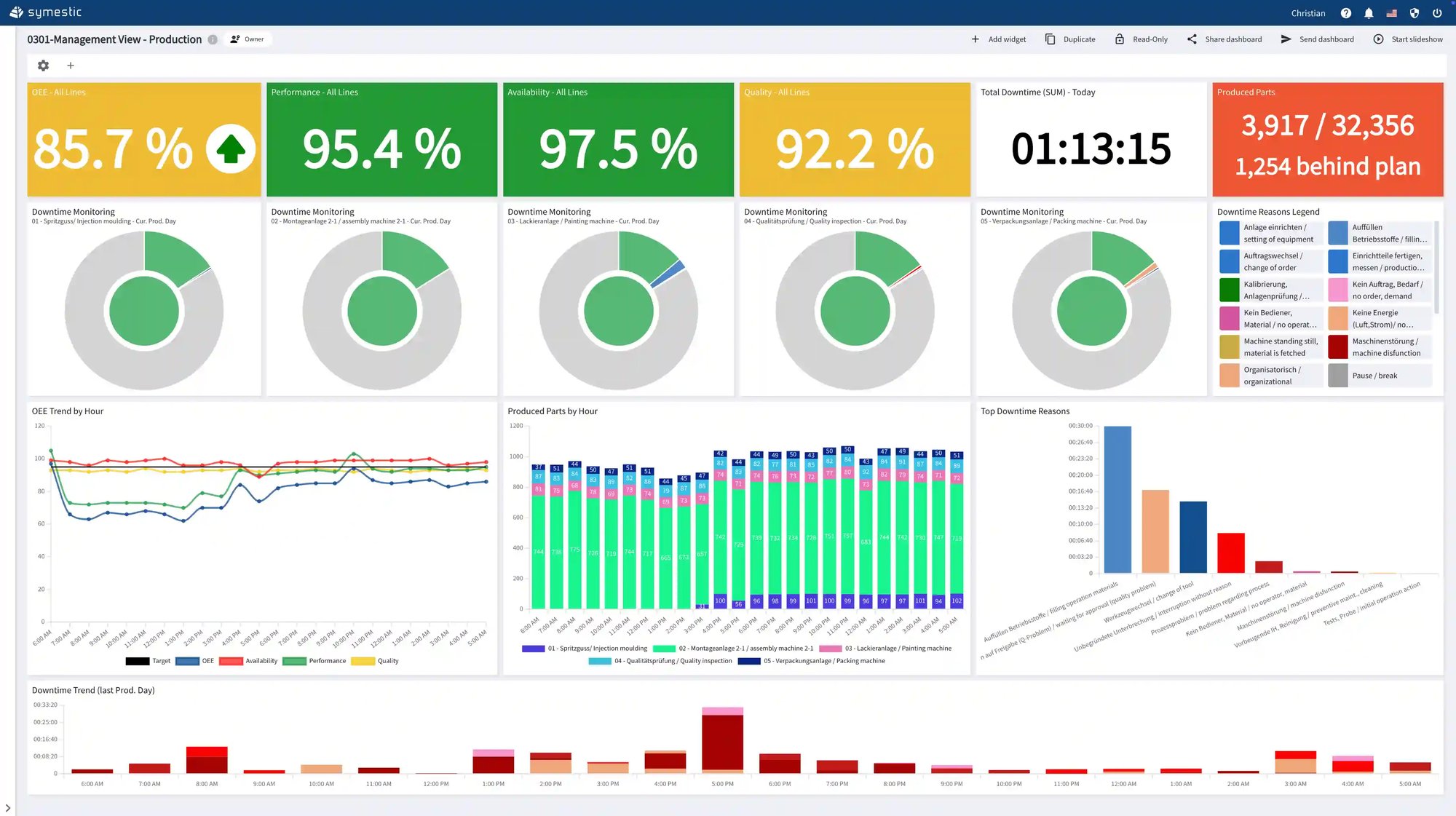

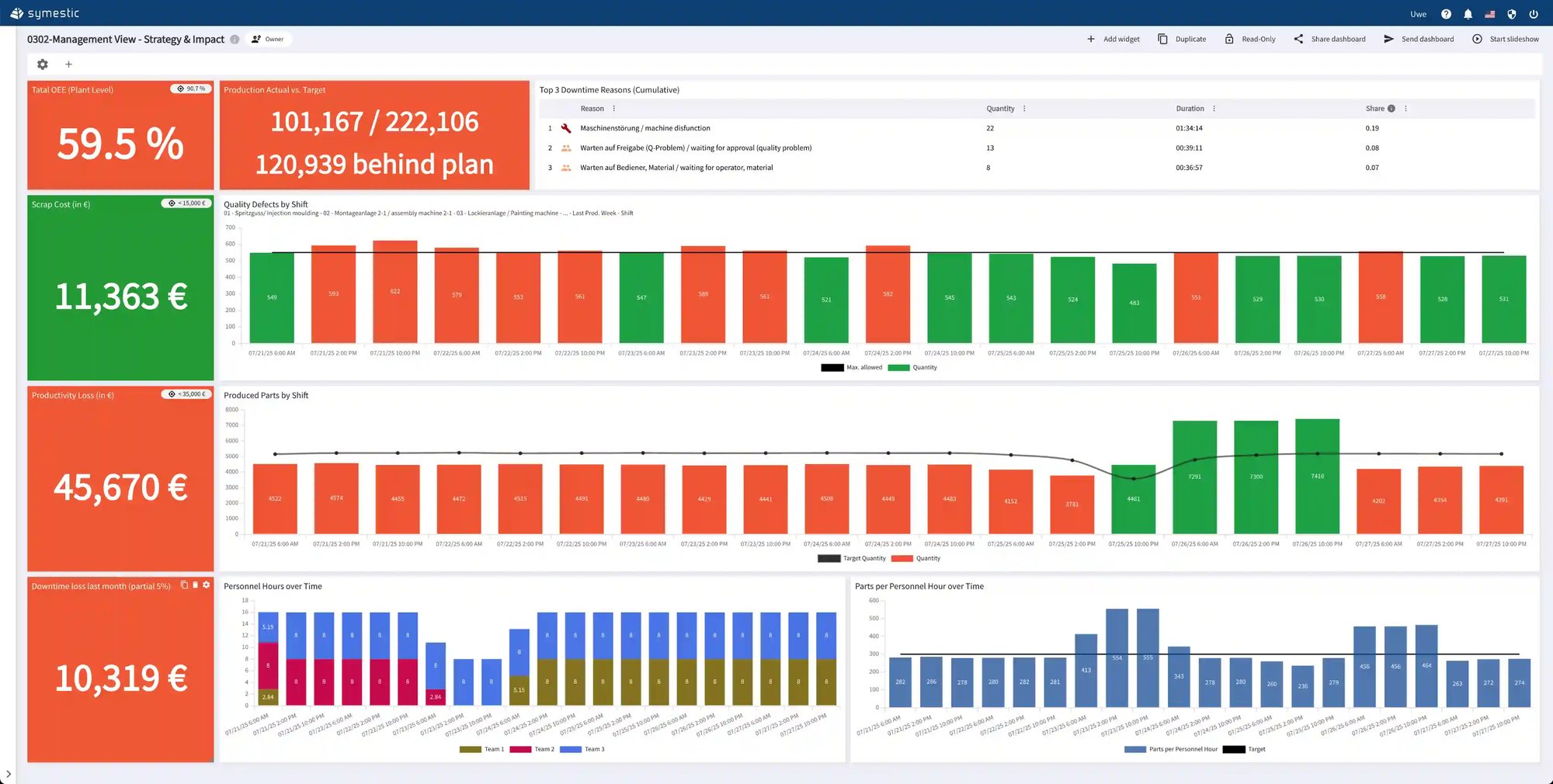

If throughput, NIO rates and root causes are not transparent, testing becomes a bottleneck and a cost driver. SYMESTIC is a cloud MES for test stands and end-of-line testing that brings full visibility from test program to serial number.

Where test and EOL areas struggle

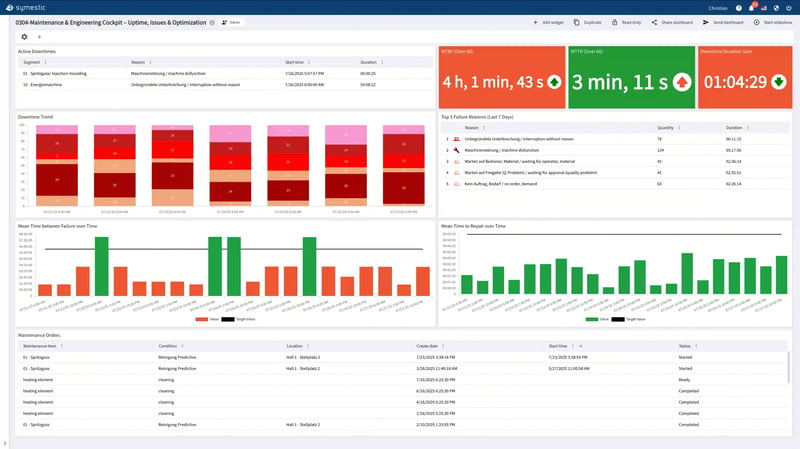

EOL testers, leak testers, electrical testers and vision systems often run in isolation. Each has its own software, local database or CSV export. NIO rates are known, but not why or from where defects originate. Links to assembly, suppliers, variants or software versions are weak. Traceability is fragmented, and complaint or audit requests trigger manual data hunts. At the same time, line managers lack a clear view of test stand utilization, queues and losses from re-tests.

How SYMESTIC Cloud MES connects test data and traceability

SYMESTIC connects your EOL testers, functional testers, leak testers, electrical testers and vision systems to a central cloud MES. Test results, measurements, test programs, IO/NIO decisions, re-tests and rework information are captured in real time and stored per serial number.

OEE for your test areas becomes visible, including losses from availability, speed and quality. Test programs, limits and release rules can be controlled variant- and customer-specific so testing follows a consistent, auditable logic.

Use cases: EOL testing, functional and leak tests

In EOL testing, SYMESTIC ties test status, measurement results, limit violations and re-tests to product variants, software levels and assembly data.

Recurring failure modes and their links to upstream processes become transparent. In functional and leak tests, test profiles, pressure curves, flows and electrical parameters are logged and connected to materials and suppliers. You gain full, digital test histories for every product without manual dossier building.

Next step: pilot SYMESTIC on a test stand

If your test and EOL areas are still driven by isolated tools, paper protocols and late Excel reports, a pilot is the next logical move. We select a critical test area, define goals for NIO rates, throughput, traceability and audit effort and bring SYMESTIC Cloud MES live in a short timeframe. You see on your own test stands how real-time transparency and serial-number traceability reduce risk and stabilize delivery performance before scaling to further areas.