MES for Machinery Manufacturing

The MES for Machinery Manufacturing from SYMESTIC is designed for highly complex, project-driven production environments. It provides complete transparency across long manufacturing cycles, supports flexible resource planning, and delivers automated production KPIs even when every order is unique.

The SYMESTIC Cloud MES adapts to the specific requirements of machine building, ensuring precise coordination from initial request to final delivery. Start your free trial and take control of complex manufacturing projects with real-time clarity and measurable efficiency gains.

Mastering the Challenges of Machinery Manufacturing

Machinery manufacturing demands a level of flexibility and planning precision unmatched in other industries. Each project has its own specifications, engineering changes occur throughout the process, and long lead times must be coordinated across multiple departments and suppliers.

Production managers must keep every step aligned while maintaining delivery deadlines despite shifting priorities and unforeseen changes.

Resource planning becomes especially demanding when capacity loads fluctuate, skilled staff are limited, and machine availability varies. SYMESTIC ensures manufacturers maintain control over every phase of complex custom production, even when requirements change on short notice.

SYMESTIC MES: Built for the Realities of Machine Building

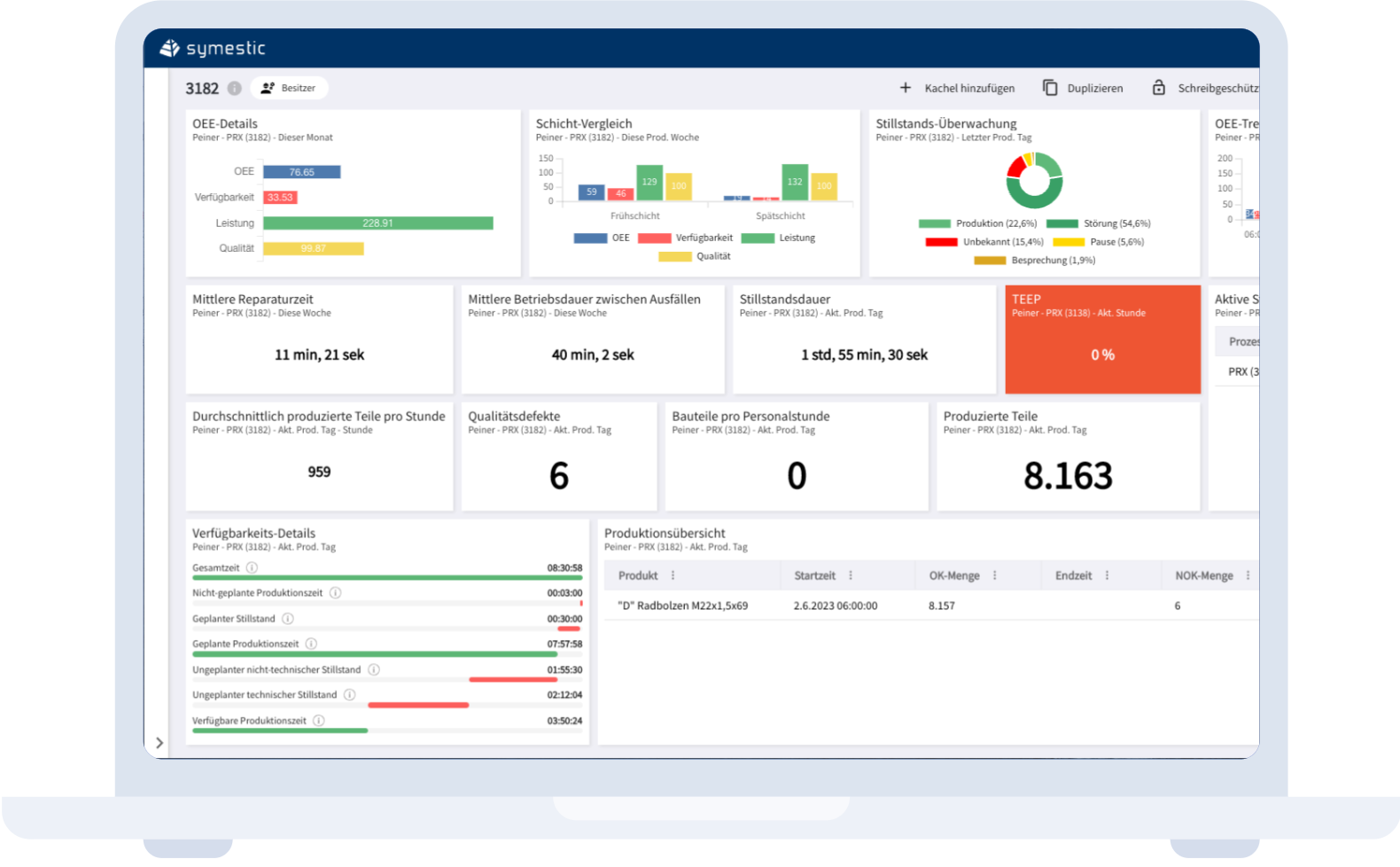

SYMESTIC provides digital production control that maps each customer project end-to-end. Orders can be tracked seamlessly from engineering through assembly and testing, with real-time updates on job status and workload distribution. Flexible routing and work plans allow manufacturers to adjust processes quickly, ensuring that teams always operate with accurate, up-to-date information.

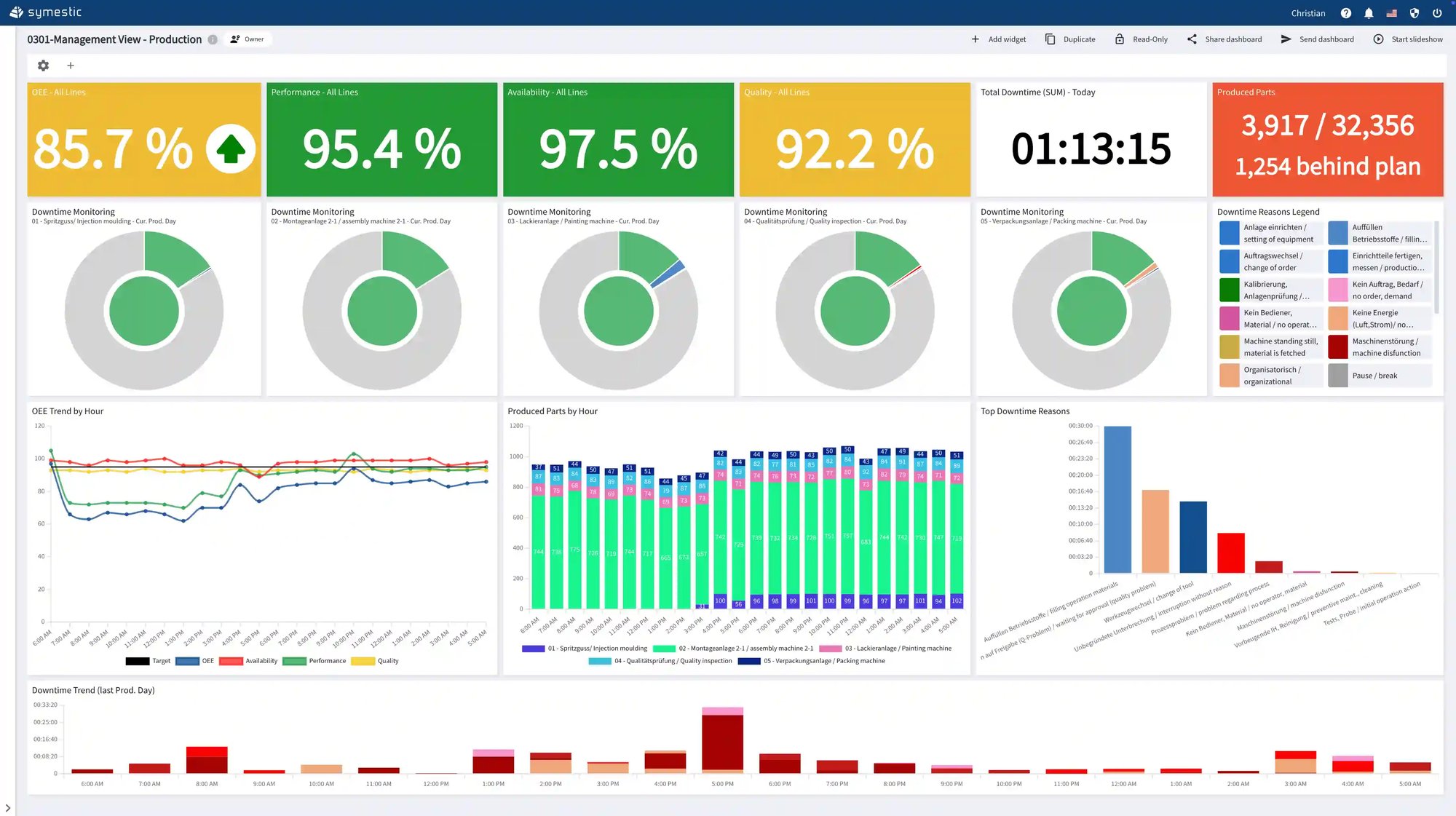

Intelligent production planning creates optimized schedules that balance shifting priorities, machine availability, and skill requirements. Delivery commitments remain reliable because the system calculates precise timelines and highlights bottlenecks before they cause delays. Automated production KPIs such as OEE reveal hidden inefficiencies even in one-off production environments, enabling continuous improvement and stronger project profitability.

SYMESTIC provides the clarity needed to make data-driven decisions and bring complex machinery projects to completion faster and with higher quality.

Proven SYMESTIC Modules for Machinery Manufacturing

SYMESTIC offers a set of manufacturing modules that map perfectly to the needs of machine builders. Digital production control ensures that every custom job is executed consistently and documented cleanly. Advanced planning and scheduling allocates staff, machines, and tools exactly where they are needed to keep long projects on track.

Real-time KPI tracking delivers actionable insights into availability, performance, and quality — even for unique production workflows. Automated alarms notify teams of emerging disruptions at critical stages, allowing immediate corrective action.

Continuous process-data monitoring supports quality stability during assembly and testing, giving manufacturers a high level of reliability across all custom-built components. Together, these modules provide a robust foundation for controlling, optimizing, and scaling machinery manufacturing.