MES for Plastics Processing

The MES for Plastics Processing from SYMESTIC optimizes complex injection-molding environments by intelligently coordinating machines, peripherals, and heterogeneous technologies. The system provides real-time visibility, stable processes, and consistent part quality across all tools and materials.

SYMESTIC is trusted by leading machine manufacturers such as Engel, Wittmann-Battenfeld, KraussMaffei, Haitian, and Husky, supported by more than two decades of automation expertise.

.png?width=1792&height=1024&name=Lean-Production%20(3).png)

Industry Challenges in Plastics Processing

Plastics manufacturing involves a unique combination of process variability, tight tolerances, and tool-dependent performance. Injection molding, extrusion, blow molding, thermoforming, and additive manufacturing each require precise parameter control, and even small deviations in temperature, pressure, or cooling behavior can cause defects or rising scrap rates.

At the same time, manufacturers must balance material costs, cycle-time targets, and machine utilization while dealing with high production volumes, short lead times, and frequent changeovers. An MES must therefore provide immediate transparency, fast root-cause detection, and stable performance across diverse machines and technologies.

SYMESTIC: Purpose-Built for Injection Molding

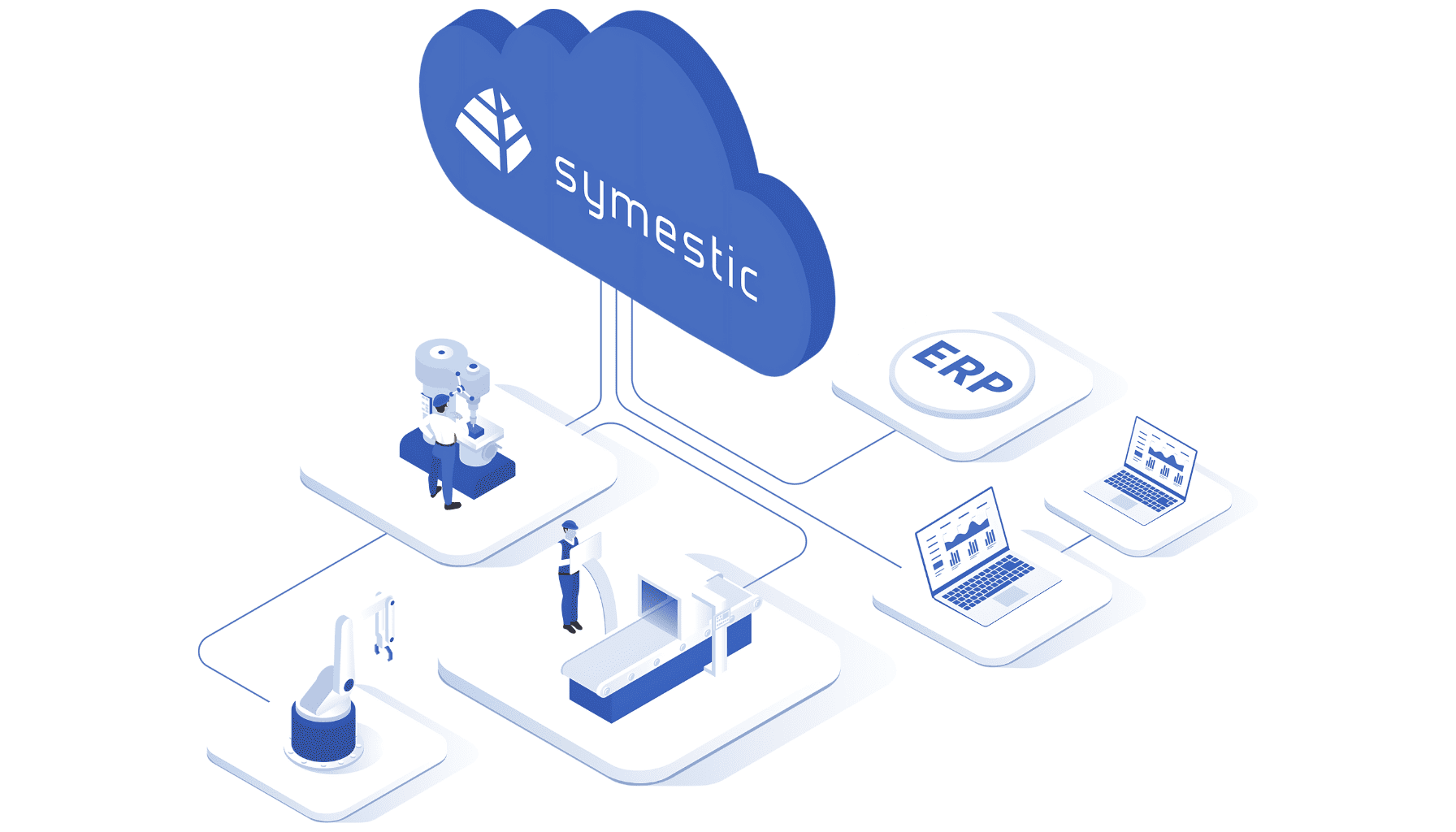

SYMESTIC offers a cloud-native MES tailored for injection molding environments. The IMM Controller creates a fully connected production cell by synchronizing the injection-molding machine with dryers, material feed systems, robots, handling units, quality inspection devices, post-processing stations, and labeling systems. This enables a unified data flow and ensures that all components operate correctly and consistently.

Through the Manufacturing Connectivity Platform, SYMESTIC consolidates Euromap, OPC-UA, and other industry standards into one unified environment. This allows you to integrate machines from different vendors, retrofit existing equipment, and build a clean digital layer across all peripherals.

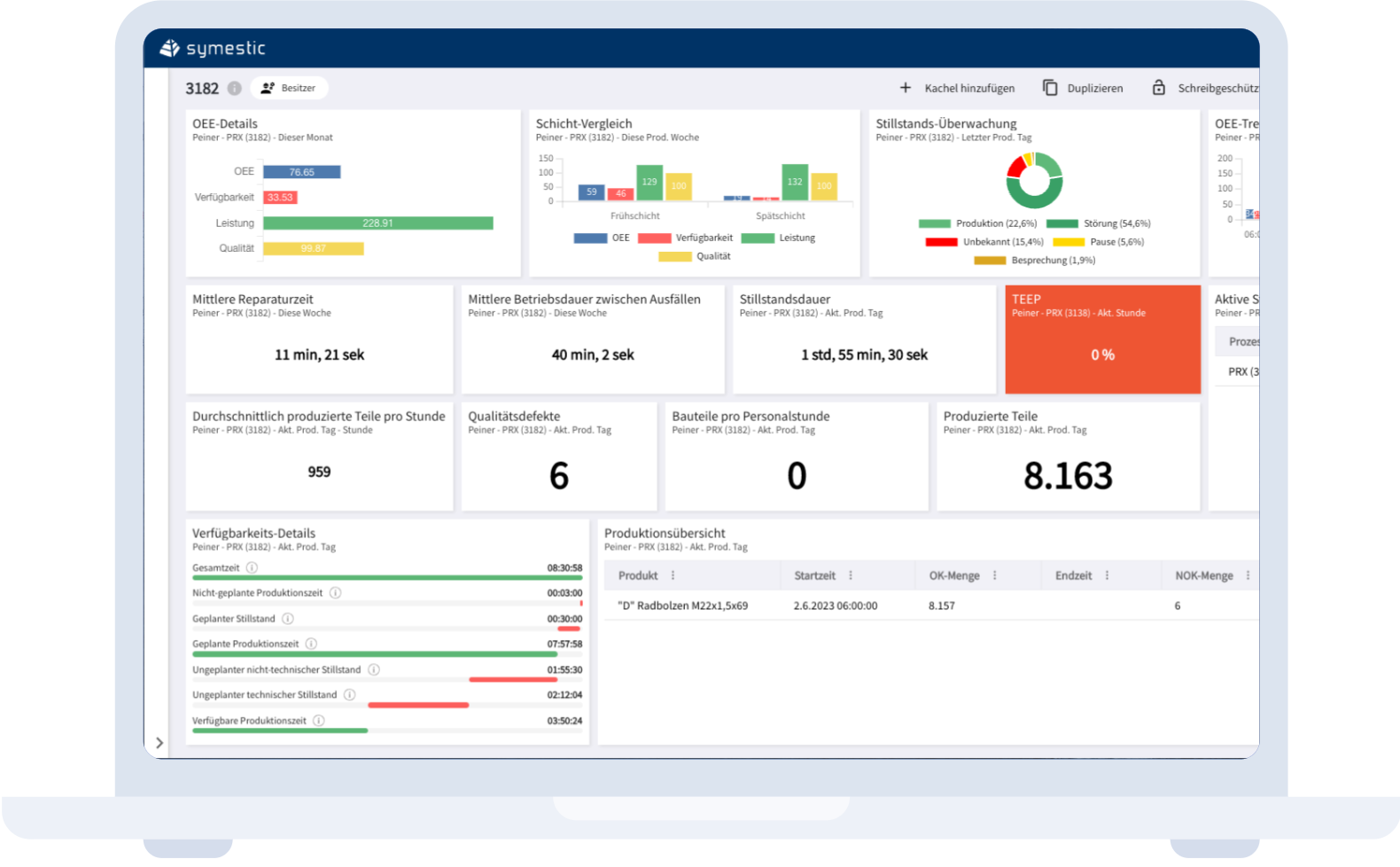

With real-time monitoring of machine performance, SYMESTIC enables continuous improvement: cycle times become stable, scrap is reduced, and KPIs such as OEE, TEEP, MTBF and MTTR become reliably measurable. This gives manufacturers clear visibility into bottlenecks, quality deviations, and hidden inefficiencies — essential for high-volume, cost-sensitive plastics production.