MES Production Control

Real-Time Shop Floor Execution

Production control with MES is the key to a lean, transparent, and highly productive manufacturing environment.

While ERP systems typically only cover high-level planning, an MES delivers real-time operational control directly on the shop floor.

With the cloud MES from SYMESTIC, you control orders, resources, and processes instantly — maximizing efficiency and quality.

.png)

Why MES Is Essential for Production Control

Many manufacturers struggle with the same issues:

- Orders do not run as planned because data arrives too late

- Downtimes and disruptions are detected too late

- Resources such as personnel and machines are not optimally utilized

An MES closes the gap between ERP and the shop floor.

It ensures that planning and reality align — and that production can react flexibly to changes.

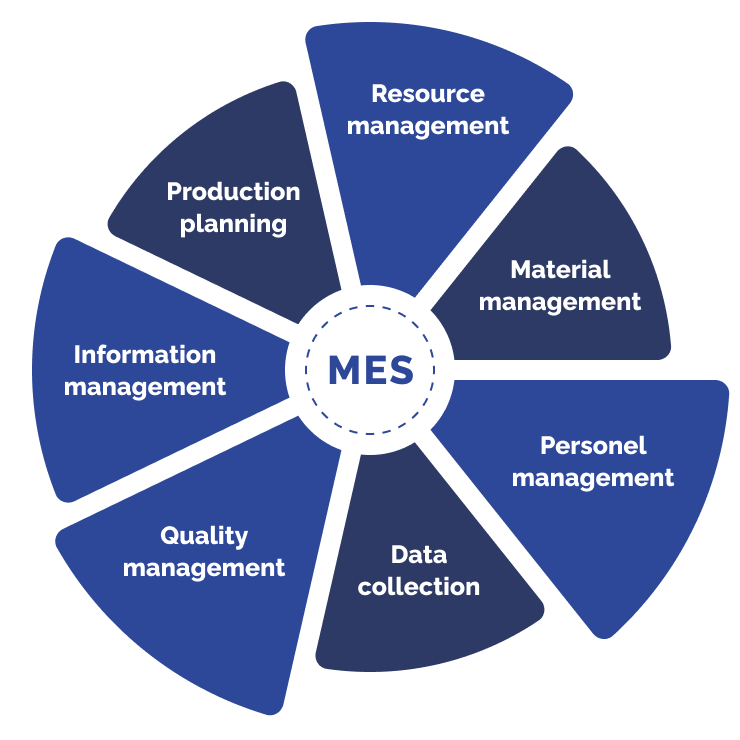

Core Functions of MES-Based Production Control

A modern MES provides all the tools required to control production in real time:

-

Order control & finite scheduling: Detailed scheduling and capacity planning at machine level

-

Resource management: Optimal allocation of operators, machines, and materials

-

Real-time monitoring: Current status of all machines and orders at a glance

-

Fast responsiveness: Immediate adjustments in case of disruptions or short-term changes

Advantages of MES Production Control With SYMESTIC

- Cloud-native: No installation, instantly ready

- Scalable: From a single line to global multi-site operations

- Flexible: Adapts to your processes without long IT projects

- Future-proof: AI-enabled, fully IoT-ready

Production Control on the Next Level

MES-based production control is the foundation of efficient, flexible, and data-driven manufacturing.

With SYMESTIC Cloud MES, you control your production in real time, reduce downtime, and sustainably increase productivity.