MES for Renewable Energy: Efficient Production of Sustainable Technologies

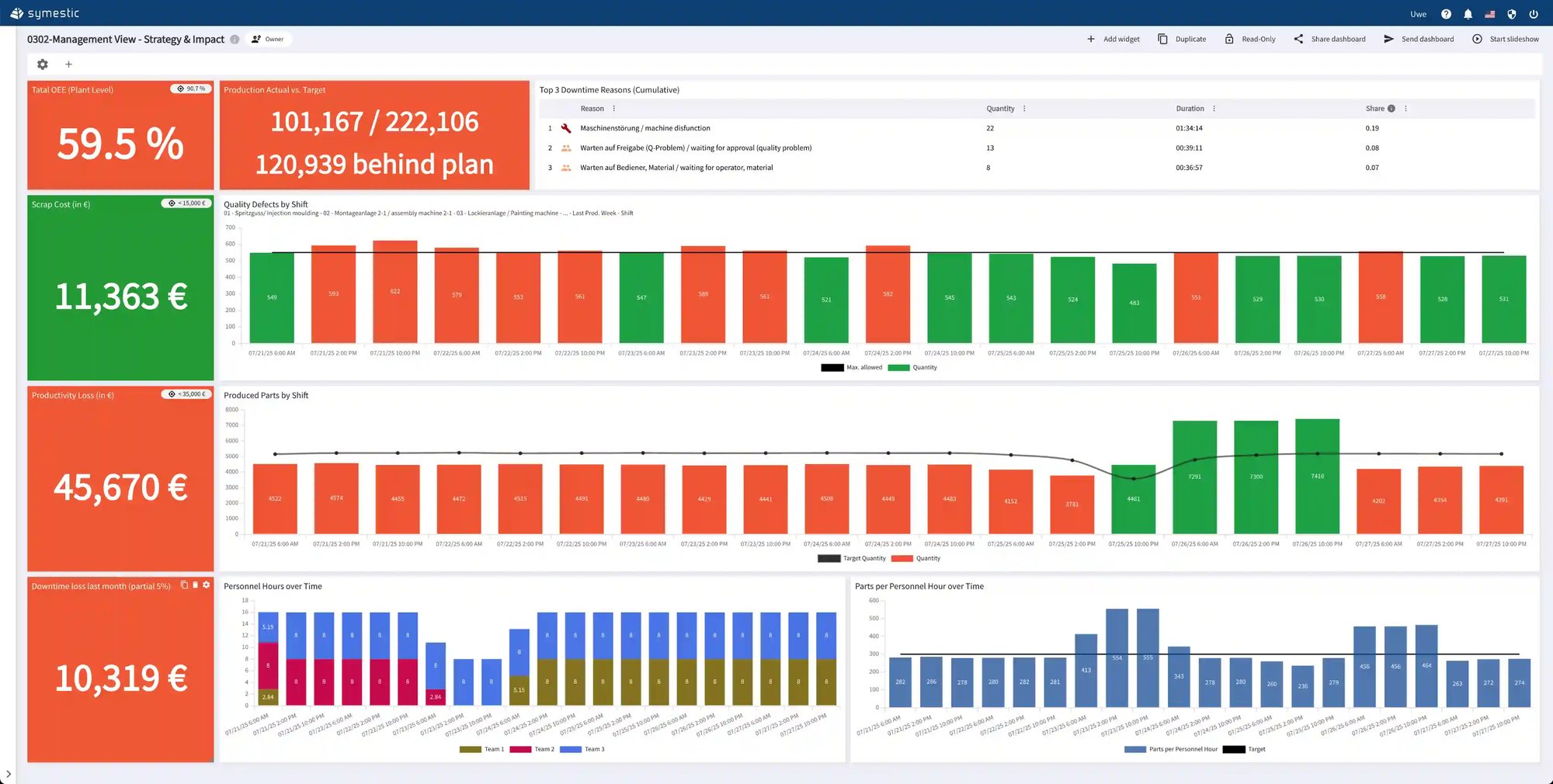

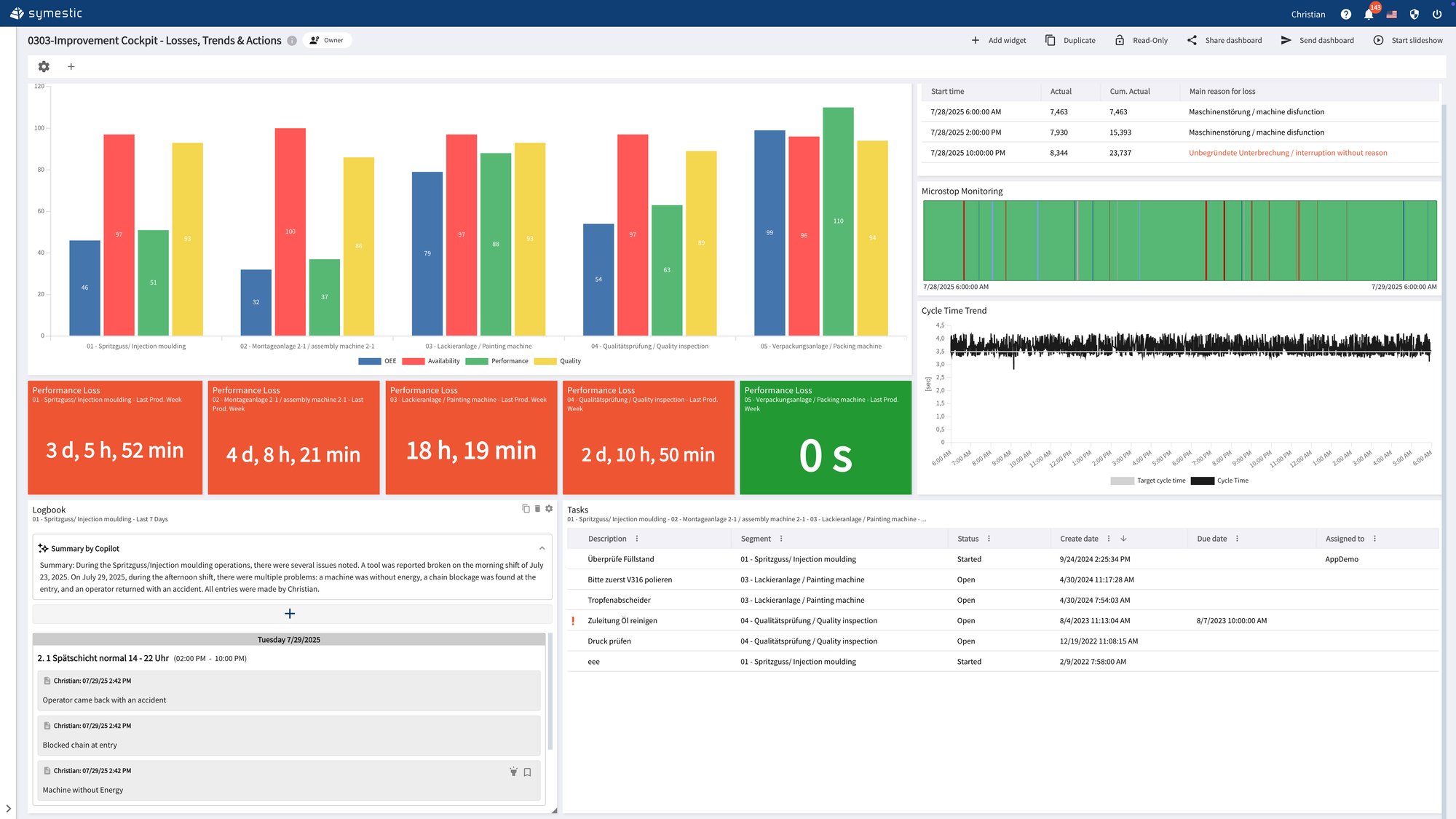

The MES for Renewable Energy from SYMESTIC optimizes battery cell, solar module, and energy-storage production through precise quality tracking, energy monitoring, and complete cell traceability.

Sustainable manufacturing becomes significantly more efficient through intelligent real-time data capture.

Renewable-Energy-Specific Challenges

Highest quality requirements

- Battery cells must perform reliably for many years

- Solar modules require 20+ years of guaranteed lifetime

- Critical production parameters must stay within extremely narrow tolerances

- Full traceability of every single cell is mandatory

Sustainability and energy efficiency

- Optimize energy consumption in the production of sustainability-focused products

- Maximize material efficiency for high-value raw materials

- Reduce the production CO₂ footprint

- Document and optimize recycling processes

Built for Green Technologies

Cell and module traceability

- Complete lifetime traceability for each individual battery cell

- Automatic linking of quality data with cell IDs

- Continuous monitoring of solar-module-specific production parameters

- Lifetime predictions based on real manufacturing data

Energy monitoring and optimization

- Continuous measurement of production energy usage

- Real-time identification of energy waste

- Transparent CO₂ footprint of each manufacturing step

- Peak-load management for sustainable operations

Quality processes for long-term reliability

- Automatic capture of all quality-critical production parameters

- SPC analytics for consistent cell-quality performance

- Correlation of manufacturing parameters with long-term test results

- Preventive quality assurance instead of late-stage inspection

SYMESTIC Modules Optimized for Renewable Energy

Specialized for battery, solar, and energy-storage production

- Process Data: Continuous monitoring of critical parameters

- Production KPIs: OEE tracking tailored to cell and module manufacturing

- Alarms: Immediate alerts for quality-critical deviations

- Production Control: Batch management with full cell traceability

- Advanced Planning & Scheduling: Energy-optimized production planning