MES for Series Production

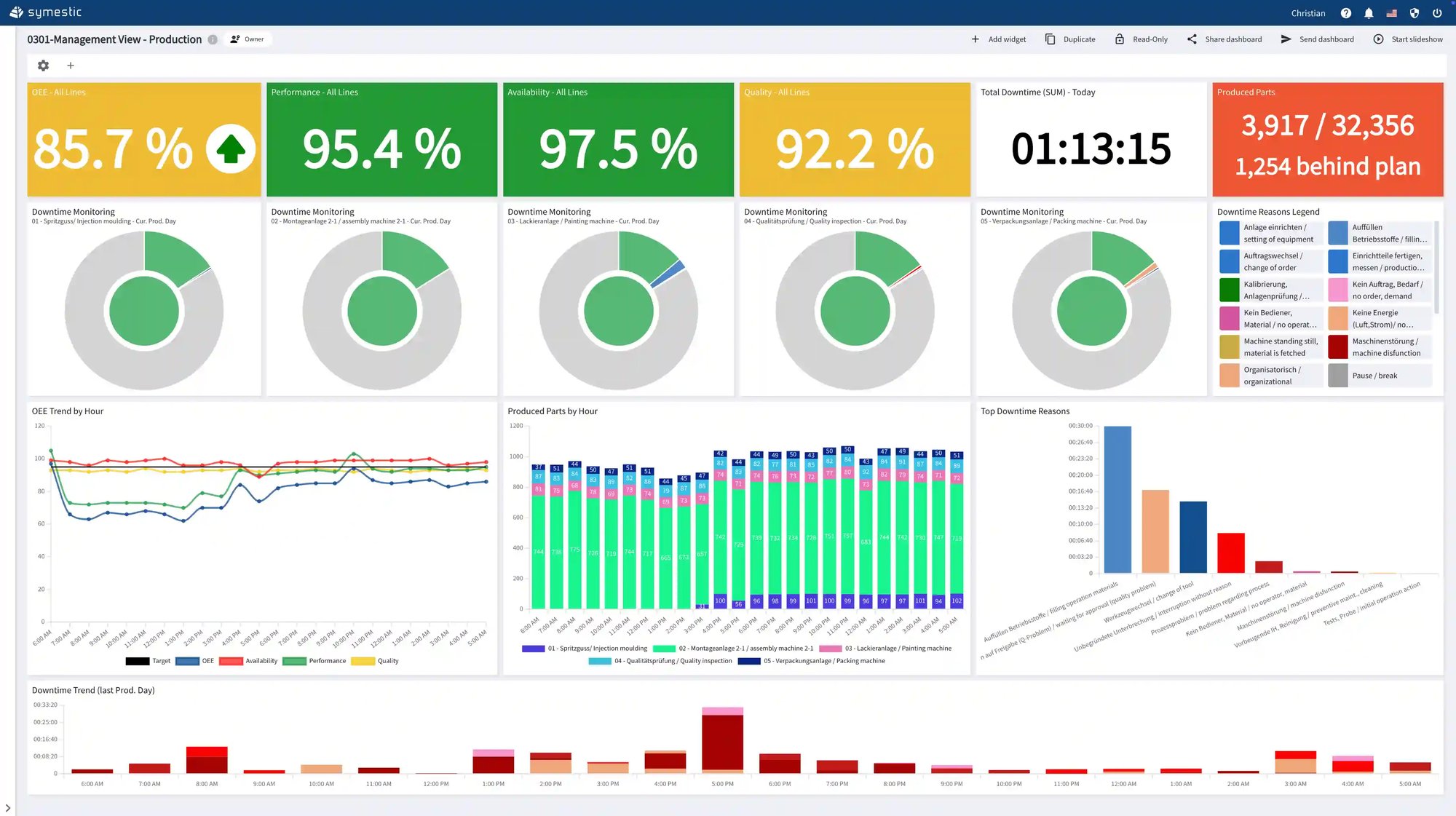

The MES for Series Production from SYMESTIC increases output in high-volume environments through precise OEE tracking, reliable cycle-time monitoring, and continuous downtime analysis. Even small efficiency gains translate directly into significant cost advantages when producing at scale. SYMESTIC ensures maximum stability across high-speed lines, long production runs, and multi-shift operations — fully cloud-native and ready to deploy within hours.

Challenges in Series Production

Manufacturers in series production rely on stable cycle times, maximum throughput, and minimal downtime. At high volumes, every interruption multiplies into major output losses. Even slight deviations in process behavior, machine performance, or material flow can reduce efficiency and escalate costs.

Quality must remain consistent across long production runs. Deviations must be detected immediately — long before large quantities are affected. Without precise, real-time transparency, teams react too late, scrap increases, and delivery reliability suffers.

SYMESTIC provides the continuous visibility needed to stabilize high-frequency production and keep performance predictable across all shifts and lines.

SYMESTIC: Built for High-Volume, High-Speed Production

SYMESTIC delivers a cloud-native MES designed specifically for highly repetitive, tightly timed production processes. OEE data is captured with high accuracy, including micro-stoppages that often remain invisible but significantly reduce throughput.

Real-time cycle-time monitoring highlights drifts early, enabling teams to prevent performance loss before it impacts output. Automated downtime analysis classifies all interruptions and reveals the true root causes behind efficiency losses, from mechanical issues to operator delays or material constraints.

Together, these capabilities enable faster reaction, more stable operation, and a higher, more predictable daily output.

SYMESTIC Modules Proven in Series Production

SYMESTIC provides all essential modules for high-volume production environments.

The Production KPIs module delivers transparent OEE benchmarking across lines and shifts.

Process-data monitoring ensures critical performance parameters remain stable, preventing slow degradation over long runs.

The Production Control module handles large batch sequences with clean execution and clear operator guidance.

And Advanced Planning optimizes changeovers, machine allocation, and daily capacity utilization for maximum throughput.

The result is a stable, efficient, high-frequency production system that consistently delivers the planned output.