MES Software

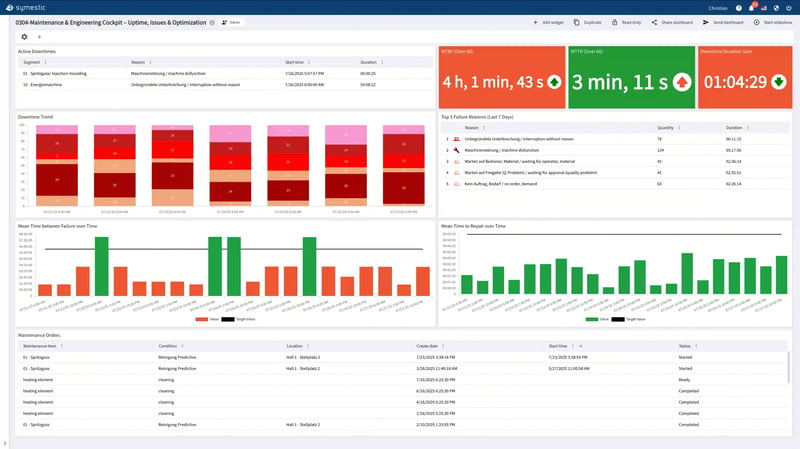

MES software (Manufacturing Execution System) provides full visibility and control over your production processes — from machine data and order execution to KPIs, quality, and continuous improvement.

With SYMESTIC Cloud MES, you digitize your shop floor in just a few hours instead of months.

Real-time insights, automatic data acquisition, and seamless scalability included.

What Is MES Software?

MES software connects your operational production processes with real-time data.

While ERP covers high-level planning, MES ensures that production actually runs as intended.

Typical MES tasks include:

- Machine and production data acquisition (MDE/BDE)

- OEE tracking and performance KPIs

- Order execution and digital work instructions

- Quality and traceability documentation

- Alarm management and process monitoring

An MES is essential for achieving efficiency, quality, and delivery reliability in modern manufacturing.

Benefits of Using MES Software

1. Real-time transparencyAll machines, orders, and KPIs visible at a glance — across all sites.

2. Lower downtime

Faster detection of bottlenecks and disruptions.

3. Higher productivity

Automated data, better planning, and optimized resource utilization.

4. Paperless production

Digital work instructions, checklists, and documentation.

5. Reliable KPI reporting

OEE, performance trends, alarms, quality data — always up to date.

MES Software With SYMESTIC

SYMESTIC offers a cloud-native MES that is productive within hours — not months.

Key advantages:

-

Fast implementation: ready in 3 hours

-

Zero IT overhead: fully managed cloud platform

-

Modular: start small, scale line by line

-

Standardized connectors: OPC UA, MQTT, REST API

-

Seamless updates: continuous development, no migration projects

This makes SYMESTIC one of the most efficient paths to digitizing your production.