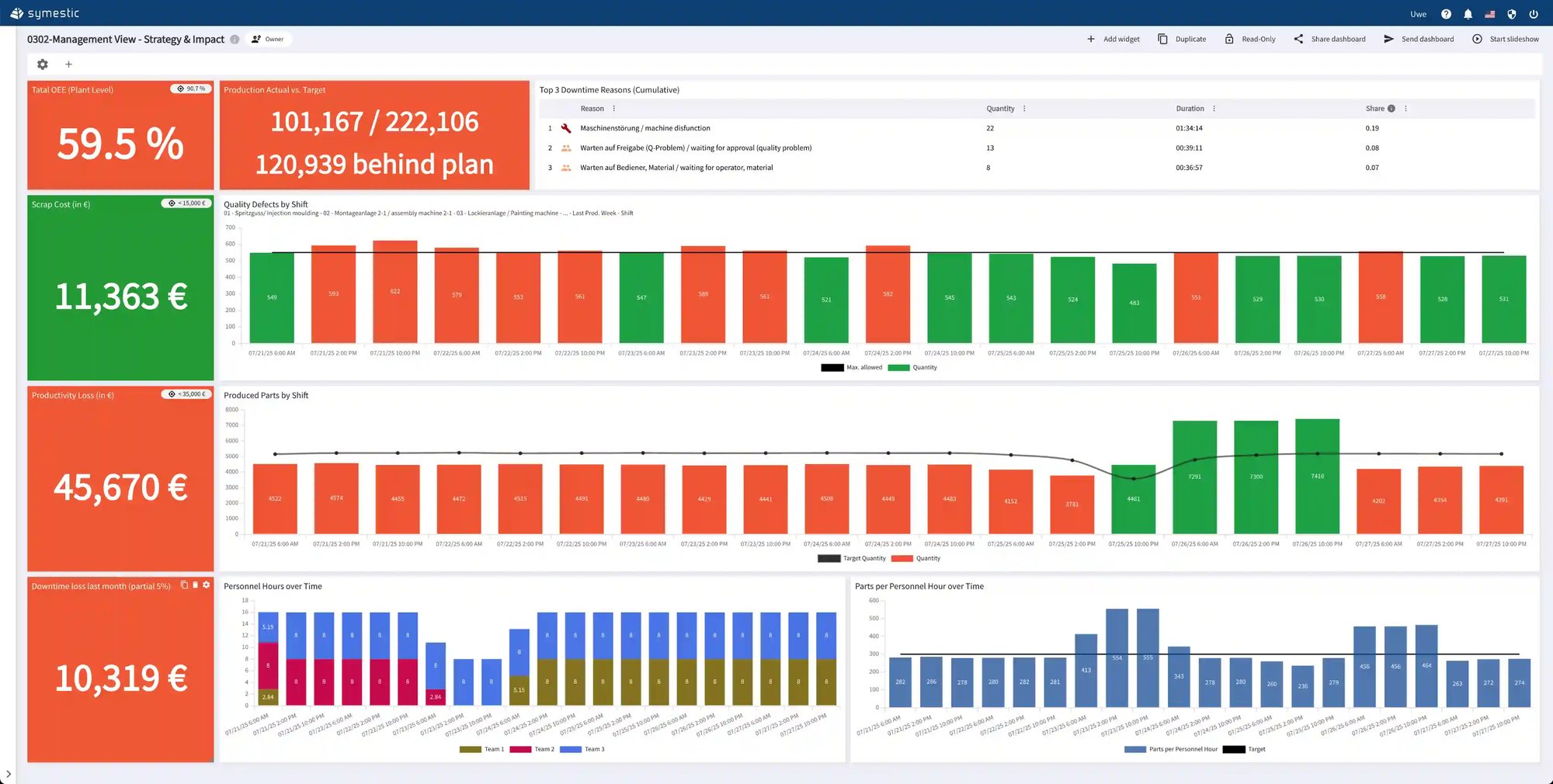

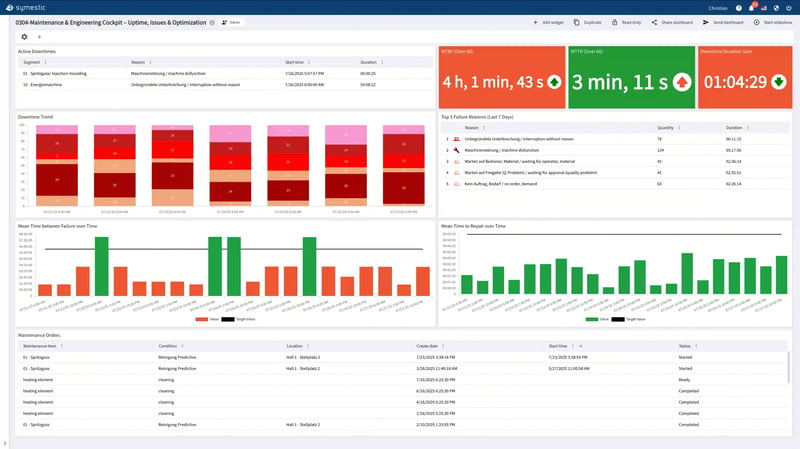

MES System Example

Many companies ask how an MES system looks in real-life practice.

With SYMESTIC, you don’t see theory—you see real, proven applications at leading manufacturers.

Our cloud MES platform is ready to use immediately and delivers measurable results from day one.

Why an MES System Example Matters

MES systems are often seen as abstract or too theoretical.

A real-world MES example shows:

-

Which production KPIs are captured in real time

-

How downtime, scrap, and utilization become visible instantly

-

Which improvements can be achieved within a short period

Practical Examples With SYMESTIC

Automotive Supplier

- Challenge: Frequent setup interruptions

- Solution: Sequence analysis via OEE dashboard

- Result: Higher throughput without additional resources

Food Manufacturer

- Challenge: Underperforming production line

- Solution: Targeted shift-plan adjustment using SYMESTIC KPI dashboard

- Result: +6% monthly output

Sanitary Supplier

- Challenge: Many machine stoppages

- Solution: Alarm data analysis focusing on four main error codes

- Result: –25% downtime

Functions Used in All Examples

-

Real-time production KPIs (OEE, output, availability)

-

Drilldowns & trend analyses for fast root-cause investigation

-

Alarm & process data management to reduce scrap

-

Mobile MES app for KPIs and alarms on the go

Benefits With SYMESTIC

-

Cloud-based & ready in 3 hours

-

Transparent pricing – from €500/month, no investment costs

-

Scalable — from pilot plant to global rollout

-

Support & onboarding included