MOM Software: Real-Time Manufacturing Operations Management

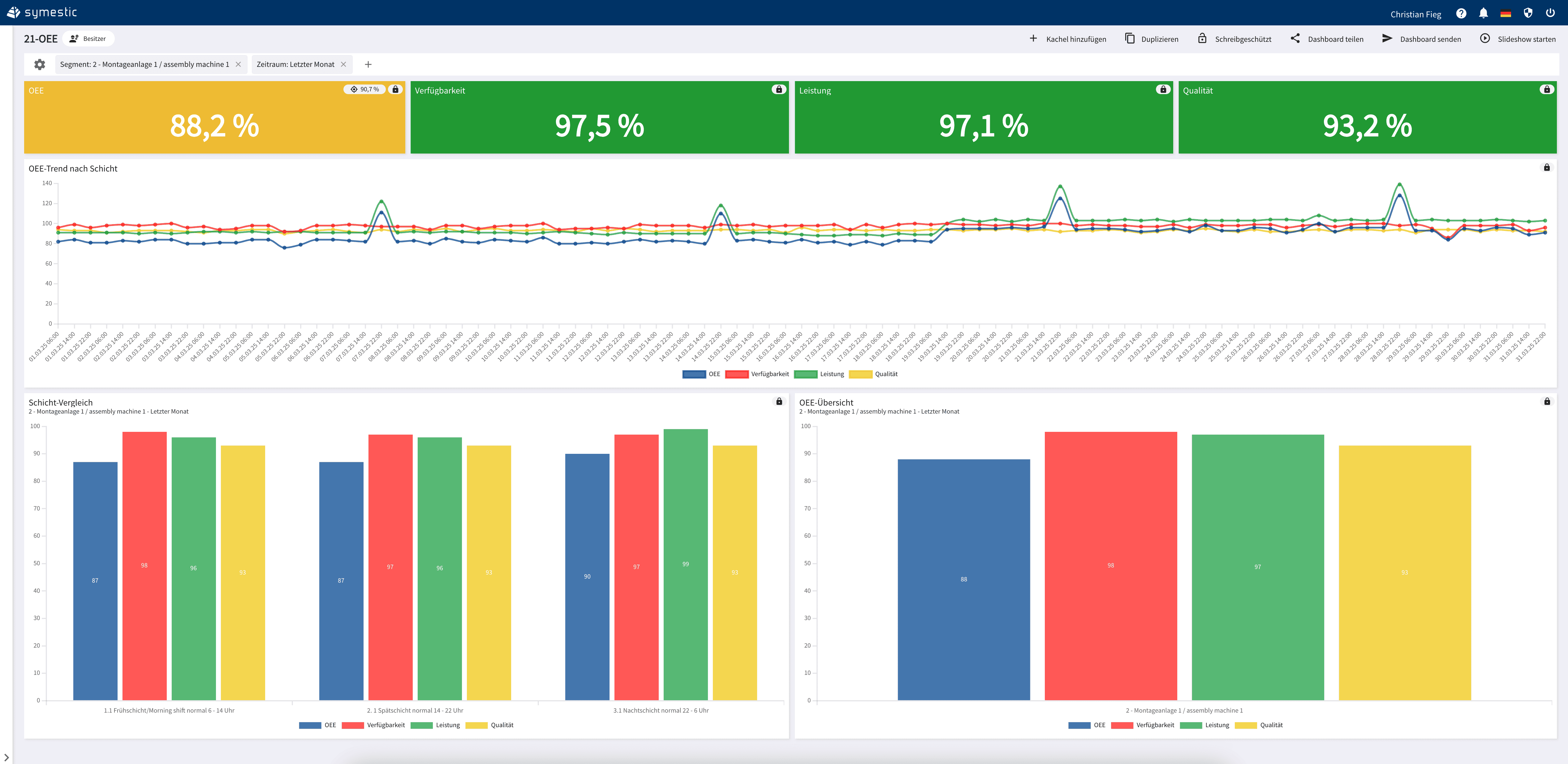

Modern MOM software provides an integrated way to plan, control, and analyze all manufacturing operations. With the SYMESTIC Cloud MES, companies unify production data, workflows, and performance metrics in one platform — fast to deploy, easy to scale, and built for Smart Factory environments.

Experience real-time visibility, automated data capture, and streamlined decision-making across every process step.

What Is MOM Software?

Manufacturing Operations Management (MOM) describes the end-to-end control, monitoring, and optimization of production processes.

Unlike traditional MES systems that focus primarily on execution and machine data, MOM software extends the scope with advanced planning, quality management, and performance analytics.

SYMESTIC brings these capabilities together in a single cloud platform, enabling manufacturers to centralize all relevant production data for maximum transparency and efficiency.

MES vs. MOM — What’s the Difference?

An MES (Manufacturing Execution System) concentrates on shopfloor control, machine connectivity, and data acquisition.

A MOM system covers a broader operational layer: it combines MES functions with planning, quality, maintenance, and business intelligence.

SYMESTIC unifies both worlds in one cloud-native platform — offering real-time execution, advanced insights, and scalable operational management without the complexity of traditional systems.

Why Manufacturers Choose SYMESTIC as Their MOM Platform

SYMESTIC is developed closely with industry partners and reflects the real requirements of modern operations leaders.

The platform delivers intuitive production control, integrated quality workflows, advanced analytics, and a unified data foundation that supports continuous improvement.

With open APIs and pre-built connectors, SYMESTIC integrates seamlessly with systems such as SAP, Microsoft Dynamics, and industry-specific ERPs, ensuring smooth data flow across all operational layers.