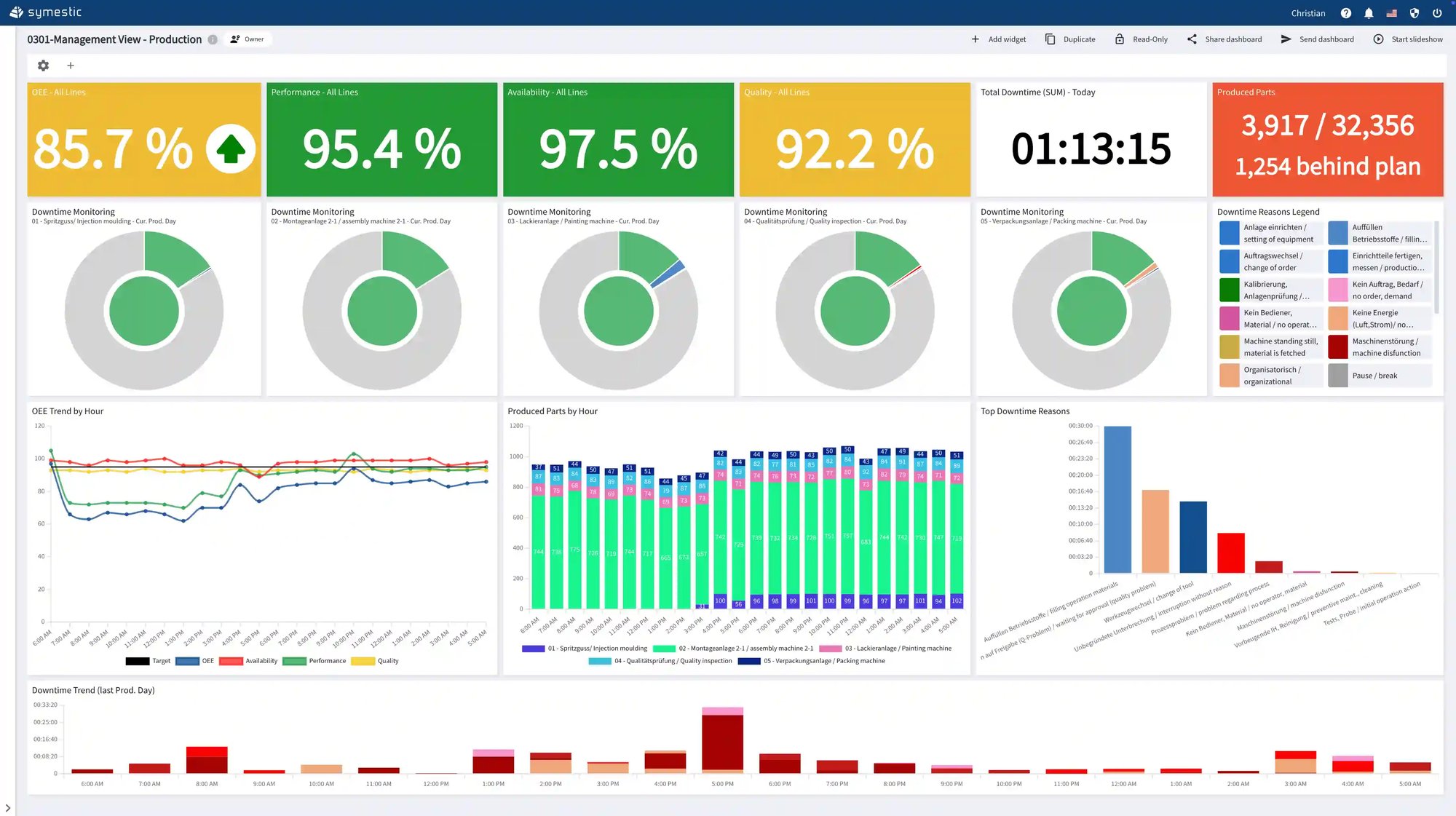

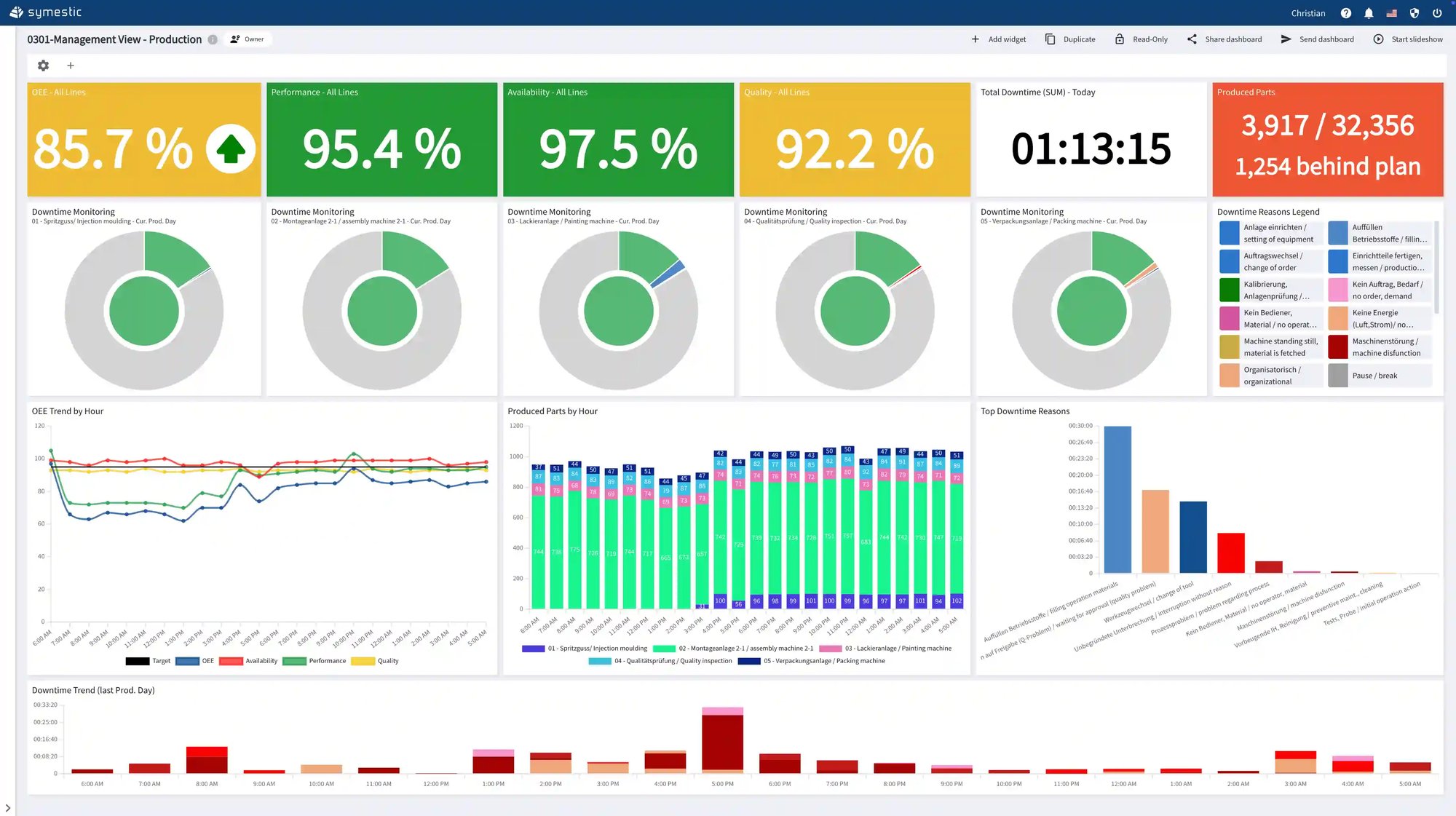

OEE Analysis: Identify and Eliminate Losses in Real Time

Effective OEE analysis reveals the true causes behind performance losses and uncovers improvement potential that remains hidden in daily operations. SYMESTIC provides a cloud-native OEE analysis engine that evaluates availability, performance, and quality continuously and in real time.

Teams see where losses originate, which root causes drive disruption, and which measures deliver the highest impact.

Why OEE Analysis Matters

Without systematic OEE analysis, manufacturers operate with unclear assumptions about where productivity is lost. Downtime reasons remain unclassified, speed losses go unnoticed, and quality issues appear too late.

Teams struggle to prioritize because every issue seems equally urgent, and improvement projects rarely produce measurable ROI.

OEE analysis replaces guesswork with facts.

It highlights the biggest loss drivers, shows how processes drift over time, and exposes recurring patterns across machines, shifts, and product variants.

This level of transparency enables targeted improvements that stabilize performance and increase throughput sustainably.

SYMESTIC OEE Analysis: Automatic, Precise, Real-Time

SYMESTIC processes machine, production, and quality data continuously to deliver a complete real-time OEE analysis.

All three loss categories — availability losses, performance losses, and quality losses — are evaluated automatically with precise timestamps and root-cause context.

Live visualizations reveal where the biggest opportunities for improvement lie, how performance develops over time, and which actions deliver the strongest impact.

Trend views, cross-machine comparisons, and shift-based evaluations create a clear and objective foundation for continuous improvement.

Focused Loss Analysis for Clear Prioritization

SYMESTIC’s OEE analysis highlights the losses that matter most.

Pareto and trend evaluations uncover the major bottlenecks and recurring root causes.

Teams see immediately where interventions create measurable value and which losses can be deprioritized.

This ensures that improvement initiatives are targeted, resource-efficient, and backed by transparent ROI calculations.