PDA Data: Fully Automatic Machine Data Collection Without Manual Input

The cloud-native PDA data capture from SYMESTIC collects all machine states, cycles, quantities, and downtimes fully automatically — without terminals, manual entries, or operator workload. All data is recorded continuously and made available in real time, creating a reliable and objective foundation for fast decisions, higher OEE, and transparent shopfloor performance.

.png)

Why Manual Data Collection Fails in Modern Manufacturing

Manual machine data reporting slows down production and creates unreliable information. Operators must interrupt their work to enter values, which leads to delays, forgotten data, or incomplete documentation. Human error distorts KPIs, and teams lose time fixing discrepancies later.

Without continuous, real-time acquisition, disturbances remain unnoticed until they cause significant losses. Efficiency drops, root causes stay unclear, and decision-making is based on subjective impressions instead of accurate machine behavior.

SYMESTIC: Automatic PDA Data With Zero Manual Effort

SYMESTIC captures all machine data automatically and processes it in real time. Machine states are tracked continuously, quantities and cycle data are recorded without operator input, and every stop receives an exact timestamp. Quality-relevant information can be captured directly from sensors and measuring devices, ensuring a consistent, objective data flow.

The data becomes visible instantly in live dashboards that show the performance across machines, lines, and shifts. Critical deviations trigger immediate alerts to prevent extended downtime or unnecessary scrap. Mobile access gives supervisors and managers full visibility wherever they are.

By combining machine, process, and production data in one unified layer, SYMESTIC enables accurate OEE calculations, transparent order tracking, and stable daily performance.

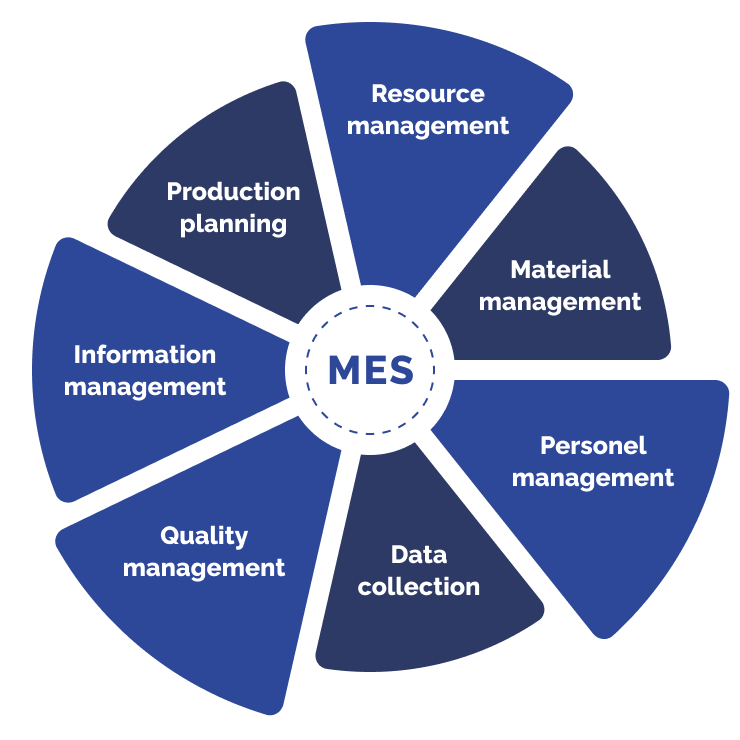

PDAas the Foundation of All SYMESTIC Modules

All PDA data flows directly into the complete SYMESTIC ecosystem. Production KPIs use it for accurate OEE and losses. Alarms classify and highlight the true causes of downtime. Production Control tracks order progress in real time, while Process Data Monitoring keeps critical parameters stable during operation.

This seamless integration ensures consistent reporting, eliminates manual reconciliation, and creates a single source of truth across the entire production environment.

Retrofit PDA for Any Machine Fleet

SYMESTIC connects to any machine, regardless of age or available interfaces. Installation is plug-and-play and requires no changes to the machine control. Older machines without digital outputs can be upgraded using sensor-based detection. Companies can start with a single machine and expand step by step — from isolated equipment to complete connected lines.

This makes PDA deployment fast, scalable, and low-risk for both small and large factories.