PDA Software: Automatic Machine Data Acquisition in Real Time

The cloud-native MDA software from SYMESTIC captures machine runtimes, downtimes, and production progress fully automatically — with no manual input, no terminals, and no local IT.

All data is collected in real time and immediately available for analysis. This creates a clean, objective foundation for higher OEE, faster decisions, and transparent shopfloor performance.

Why Modern PDASoftware Is Essential

Manufacturers lose output when they cannot see machine states, disturbances, or order progress as they happen. Without real-time transparency, efficiency drops remain hidden, and teams react too late.

SYMESTIC closes this gap by capturing all machine data directly at the source. Real-time visibility into performance makes daily production predictable, reduces losses, and improves decision-making across teams.

SYMESTIC: Automatic PDA With Zero Manual Effort

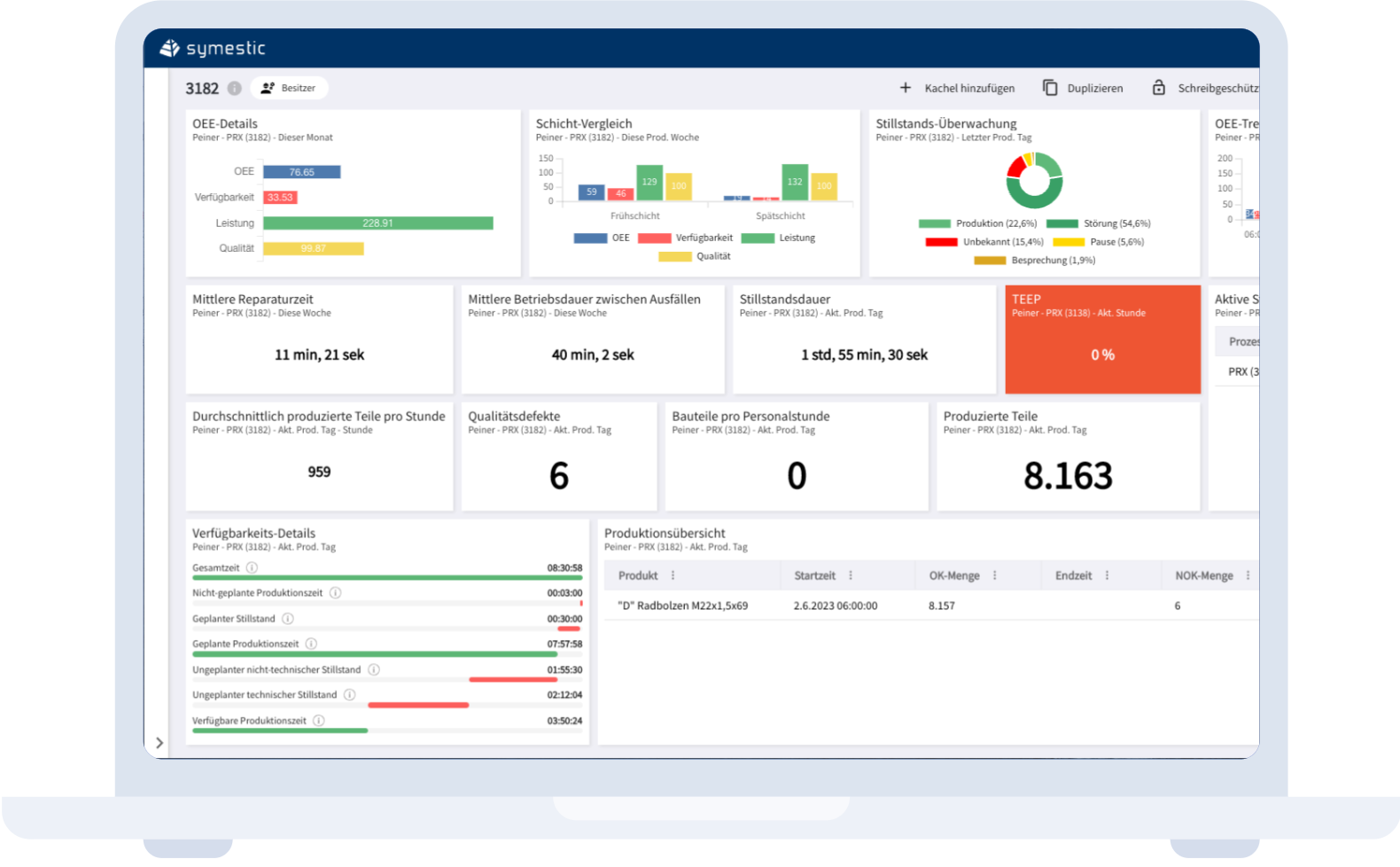

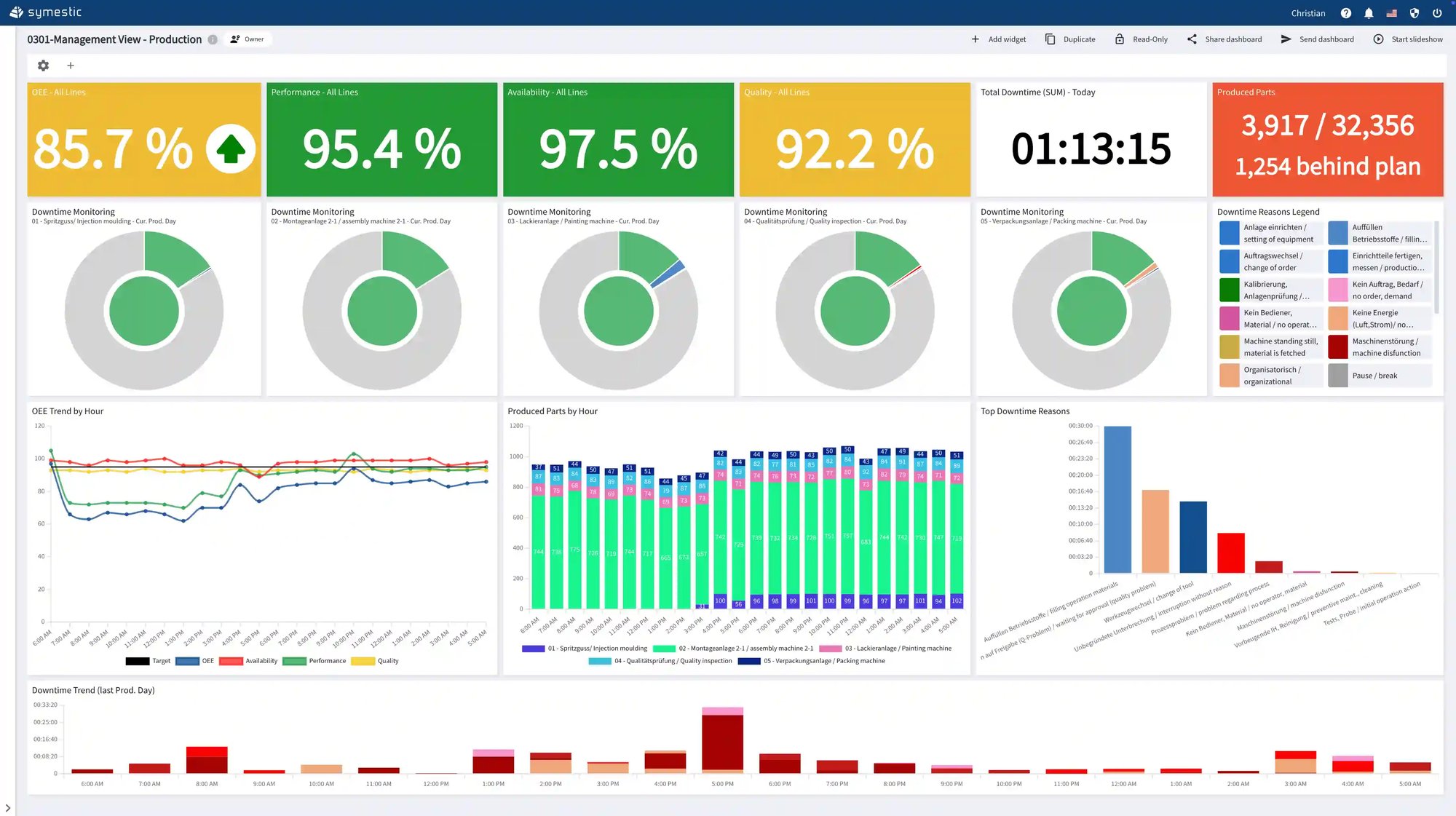

SYMESTIC records all machine data continuously and in real time. Machine states are tracked automatically, cycle data is captured without operator interaction, and each interruption receives an exact timestamp.

Operators stay focused on production while the system provides complete, accurate data in the background.

All information becomes available immediately in live dashboards that highlight machine performance, current stops, and order progress. Critical deviations trigger instant notifications so teams can act before losses escalate.

By merging machine, process, and production data into a unified layer, SYMESTIC enables accurate OEE calculation and stable daily performance across the entire shopfloor.

PDA Software That Goes Live in Hours

The cloud-native architecture removes all traditional barriers. No local servers, no installations, no long projects. Companies start within hours — fully operational and ready to collect machine data automatically.

This makes MDA implementation low-risk and accessible for any production environment.