Plant Monitoring Software

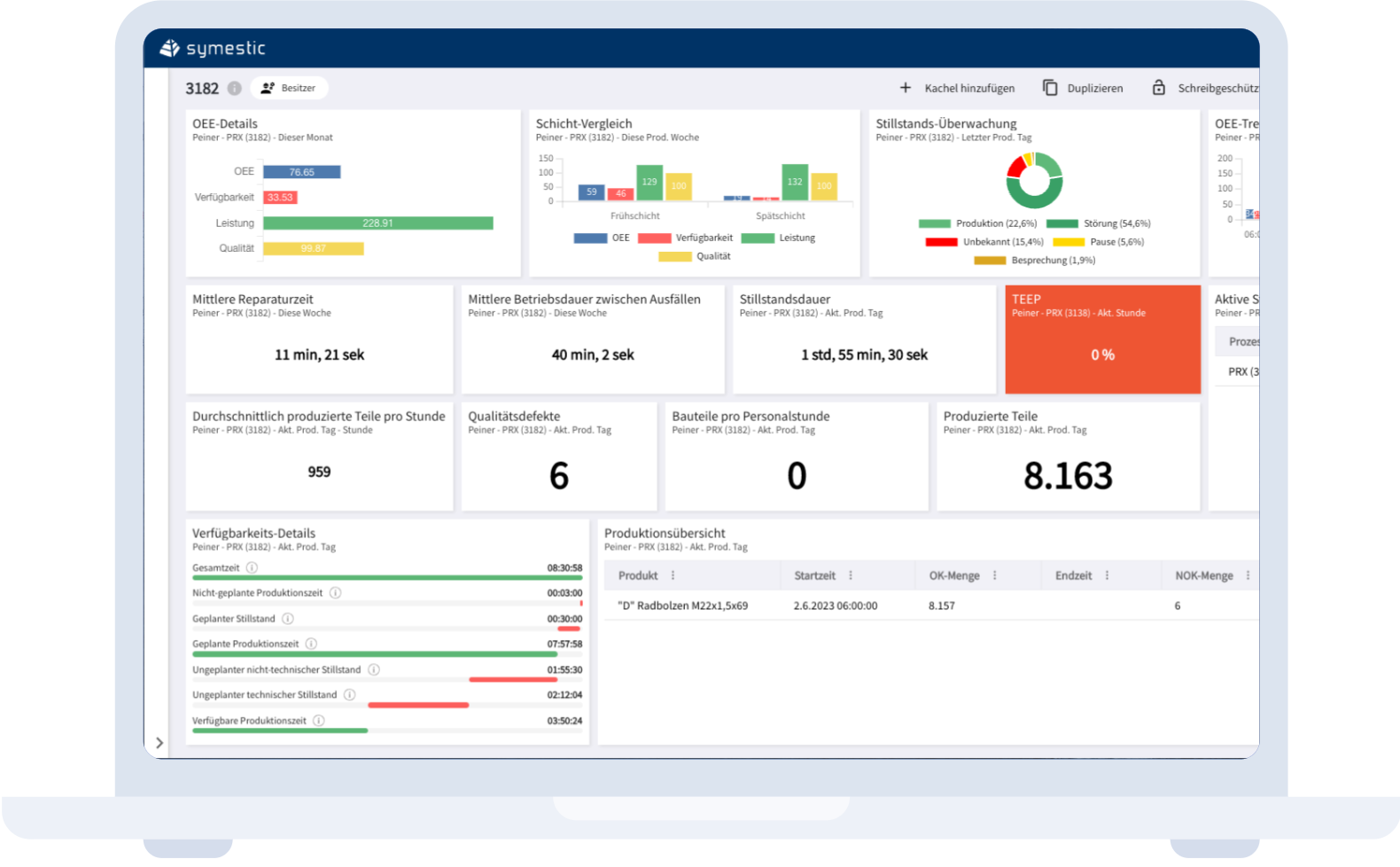

SYMESTIC Plant Monitoring Software gives you real-time visibility into the health and performance of every asset on the shop floor.

The system collects machine data automatically, detects anomalies instantly and highlights emerging risks before they escalate into downtime.

This turns maintenance from reactive firefighting into a proactive, data-driven process that safeguards equipment availability.

Why Plants Struggle Without Continuous Monitoring

Without a monitoring system, teams rely on manual checks, subjective assessments and calendar-based maintenance cycles.

Critical conditions often remain unnoticed until a breakdown occurs, disrupting schedules and inflating repair costs.

Operators and maintenance staff lack transparent insights into vibration, temperature, runtime and wear trends — making prioritization difficult and increasing unexpected stoppages.

Missing real-time visibility creates avoidable losses in availability, throughput and overall equipment efficiency.

Intelligent Real-Time Monitoring With SYMESTIC

SYMESTIC continuously captures equipment parameters around the clock, identifying patterns that indicate degradation long before a failure happens.

Live dashboards reveal trends in performance and wear, enabling early intervention at the optimal moment.

The system also sends instant alerts when thresholds are exceeded, ensuring that maintenance teams act before production is impacted.

This transforms condition monitoring into a precise, automated workflow that protects uptime and stabilizes production processes.

Predictive Maintenance That Reduces Downtime

By analyzing historical data and real-time signals, SYMESTIC recommends the best maintenance timing based on actual equipment condition.

Machines are serviced neither too early nor too late, minimizing unnecessary work while preventing breakdowns.

Maintenance activities can be aligned with production schedules to avoid disruption and reduce total cost of ownership.

Predictive insights help teams shift from reactive repairs to planned interventions with measurable impact on availability.

Easy Retrofit Monitoring for Any Machine

SYMESTIC works across all asset types, from modern CNC systems to older machines without native digital outputs.

Non-intrusive sensors, plug-and-play modules and standard interfaces allow fast onboarding without modifying existing controls.

Plants can start with a single critical machine and scale monitoring across the entire facility as needed.

Standardization across lines and sites ensures consistent visibility and unified decision-making.

Start Monitoring Your Plant in Real Time

Increase equipment availability, reduce unplanned downtime and enable predictive maintenance with a cloud-native monitoring platform.

Begin your free 30-day trial and experience how SYMESTIC elevates stability and performance across all assets.