Predictive Maintenance Software

SYMESTIC Predictive Maintenance Software uses real-time machine data to forecast failures, optimize maintenance timing and eliminate unplanned downtime.

The cloud-native platform analyzes operating patterns continuously, detects anomalies early and provides actionable insights without requiring complex AI projects.

Start your free 30-day trial and turn machine data into reliable maintenance predictions.

Why Predictive Maintenance Is the Future of Maintenance

Traditional maintenance is either too early or too late.

Predictive maintenance identifies the optimal intervention point, reducing both cost and risk.

Machine signals are analyzed continuously to detect wear patterns, performance drifts and behavior anomalies.

Manufacturers using predictive maintenance typically reduce unplanned failures dramatically and stabilize production with data-driven decisions.

With SYMESTIC, predictions begin within hours because existing machine data is leveraged immediately — no lengthy onboarding, no custom integrations.

.png?width=1792&height=1024&name=Lean-Production%20(3).png)

Predictive Maintenance With SYMESTIC

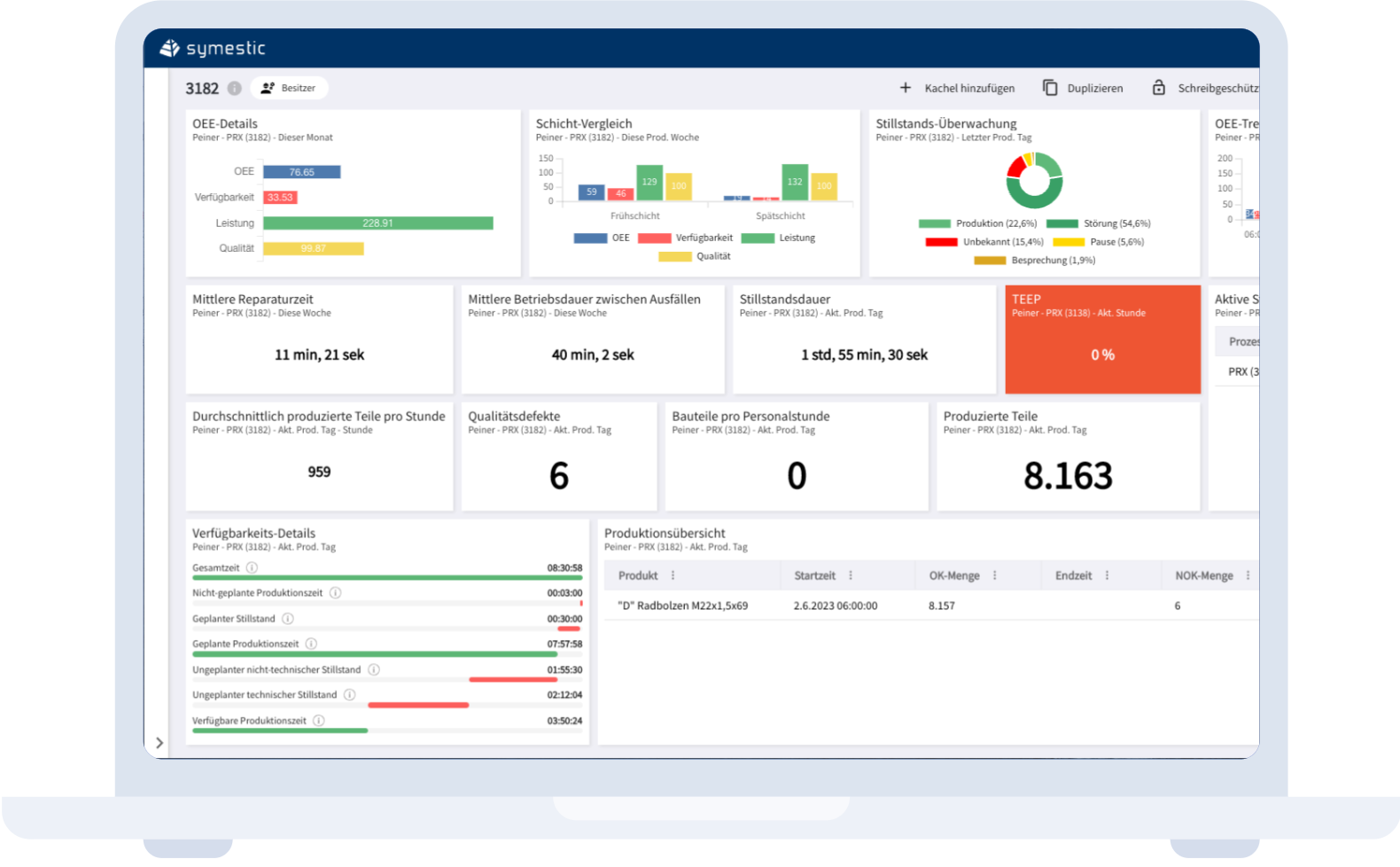

SYMESTIC links live machine data, operating hours, condition signals and process trends in one unified platform.

Algorithms highlight emerging risks and point maintenance teams directly to the components or processes that require attention.

Maintenance efforts become proactive instead of reactive.

Teams work with clear recommendations, minimal guesswork and full transparency across all equipment.

The platform evolves with your data volume — initial baseline predictions start instantly, and accuracy increases over time as more historical context becomes available.

Fast Deployment — No Complex AI Project Required

The SYMESTIC Cloud MES enables predictive maintenance from day one.

Retrofit-ready data collection captures critical metrics without hardware replacements, and insights are available immediately.

Condition trends, anomaly detection and predictive alerts help teams intervene before failures escalate.

Mobile access ensures that recommendations and machine health status are visible at all times.

Predictive maintenance becomes a practical, scalable tool — not a multi-year transformation project.

.png?width=1792&height=1024&name=MES%20(2).png)