Production Control Software

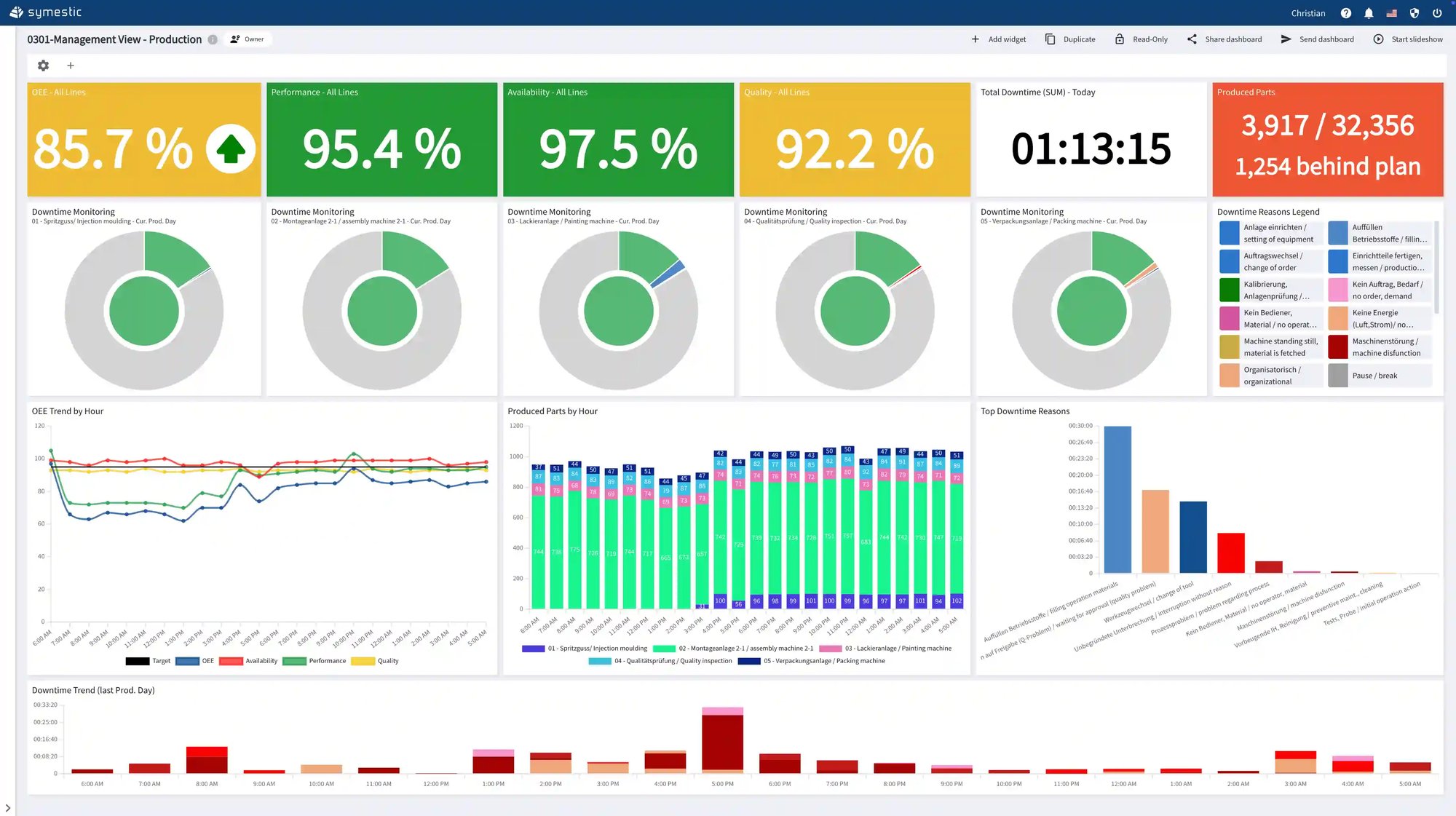

SYMESTIC’s production control software gives manufacturers complete, real-time visibility into orders, machines, and processes. Instead of Excel sheets, handwritten notes, or disconnected legacy systems, teams control their entire shopfloor digitally, centrally, and with clear data.

Whether you're running single orders or high-volume series production, SYMESTIC ensures that you always know the current order status, machine utilization, and disruptions that impact throughput.

Why Production Control Matters

Stable production depends on knowing exactly what is happening on the shopfloor. Without real-time data, delays remain hidden, disruptions escalate, and teams react far too late.

SYMESTIC provides continuous transparency by connecting machines, operators, and processes into one unified control environment.

Digital feedback replaces manual reporting; information flows automatically; and every team member works with consistent, up-to-date data.

This results in faster reactions, fewer errors, and a more predictable daily production flow.

How SYMESTIC Enhances Production Control

SYMESTIC turns the shopfloor into a fully digital, real-time control system.

Orders are executed digitally, machine states update automatically, and all KPIs — from cycle times to availability — are available instantly.

Operators receive clear instructions; supervisors see every relevant event across the line; and management gains a consolidated view of production performance.

The platform supports both simple and highly dynamic environments and adapts to the needs of multi-site operations without extra configuration effort.