Production Controlling Software: Real-Time KPIs and Operational Visibility

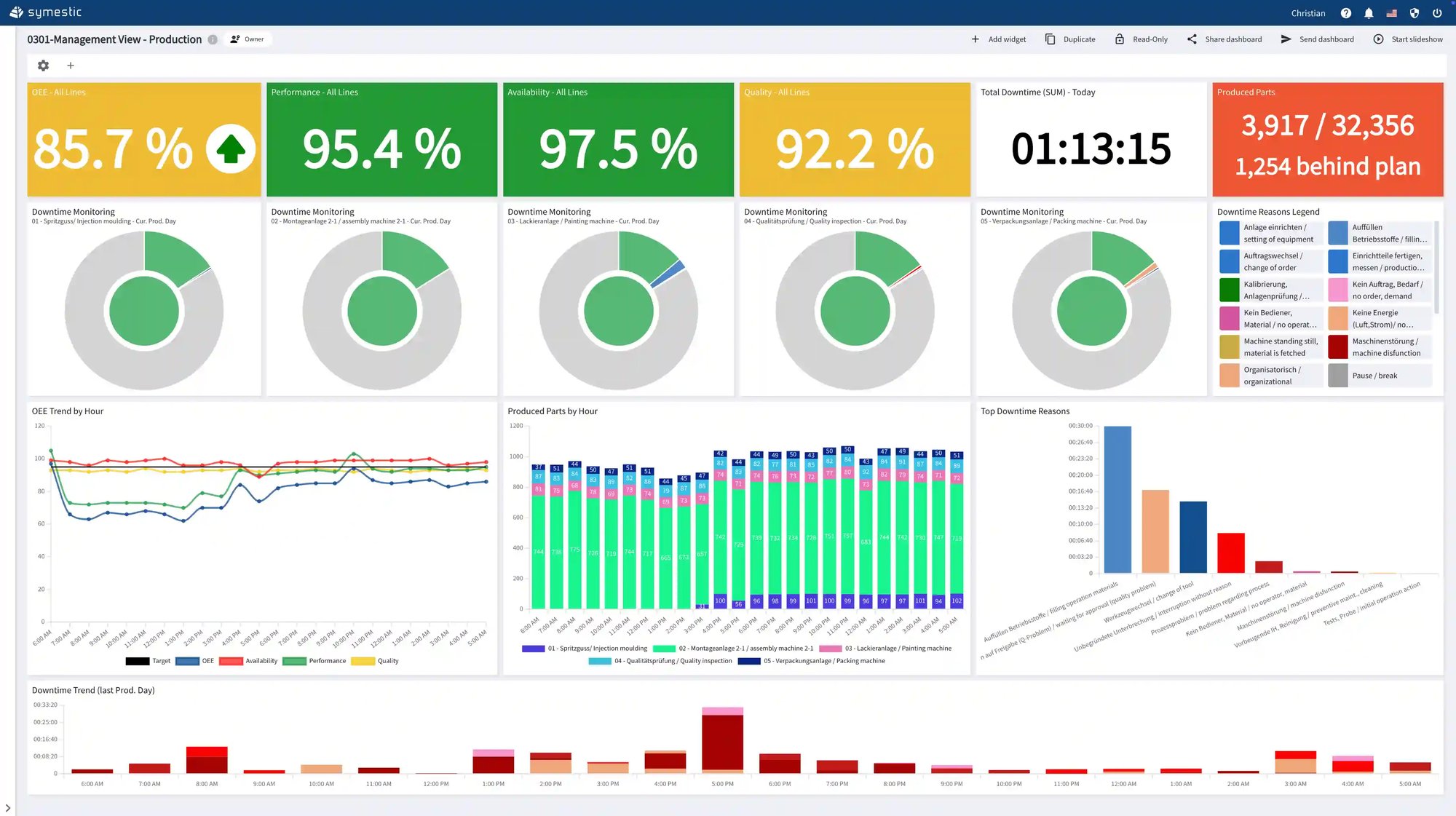

Production controlling software gives manufacturing leaders the ability to manage operations based on real, continuous performance data. SYMESTIC delivers all essential production KPIs, including OEE, downtime insights, shift comparisons, and order progress — automatically and in real time.

The cloud-native platform provides a clear and actionable view of your shopfloor, enabling faster decisions and measurable productivity gains.

Why Production Controlling Matters

Without structured production controlling, teams work with delayed or incomplete information. Losses remain hidden, improvement opportunities stay undiscovered, and decisions rely more on intuition than on facts.

Real operational excellence requires automatic data collection, transparent KPIs, and an always-updated view of what is happening on the shopfloor.

Traditional methods such as manual logs or spreadsheet-based evaluations are too slow and error prone. They cannot support real-time reactions or cross-shift benchmarking.

A modern production controlling system gives manufacturers the clarity needed to stabilize processes, reduce downtime, and increase throughput.

Core Capabilities of SYMESTIC Production Controlling Software

SYMESTIC captures all relevant production metrics directly from machines and processes. Quantities, cycle times, availability data, and live OEE are calculated automatically and visualized in intuitive dashboards.

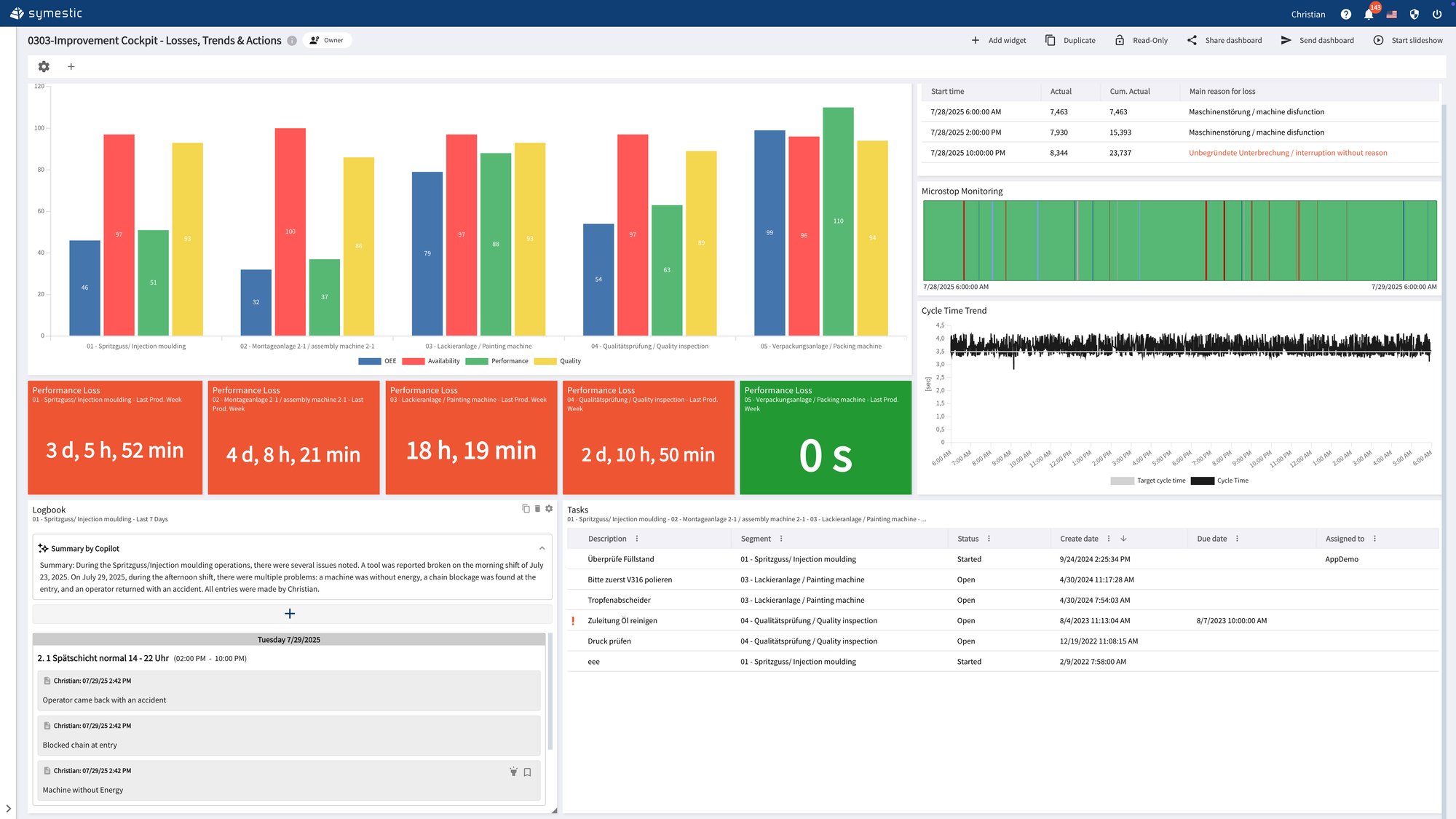

The platform reveals performance trends, highlights critical losses, and enables deep-dive analysis into the true causes of inefficiency.

Shift and line comparisons show how different teams perform, helping identify best practices and improvement potential.

Downtime events are categorized with precise timestamps, allowing teams to prioritize their improvement activities based on economic impact rather than assumptions.

Real-Time Transparency Without IT Overhead

SYMESTIC is fully cloud-based and ready within hours — without long implementation phases or internal IT projects.

All data is processed and synchronized automatically, eliminating manual effort and preventing inconsistencies.

Teams gain immediate visibility into their production performance and can act earlier, faster, and with greater confidence.

The system scales smoothly, from a single line to multiple production sites, while maintaining a unified KPI framework across the entire organization.