Production Monitoring Software

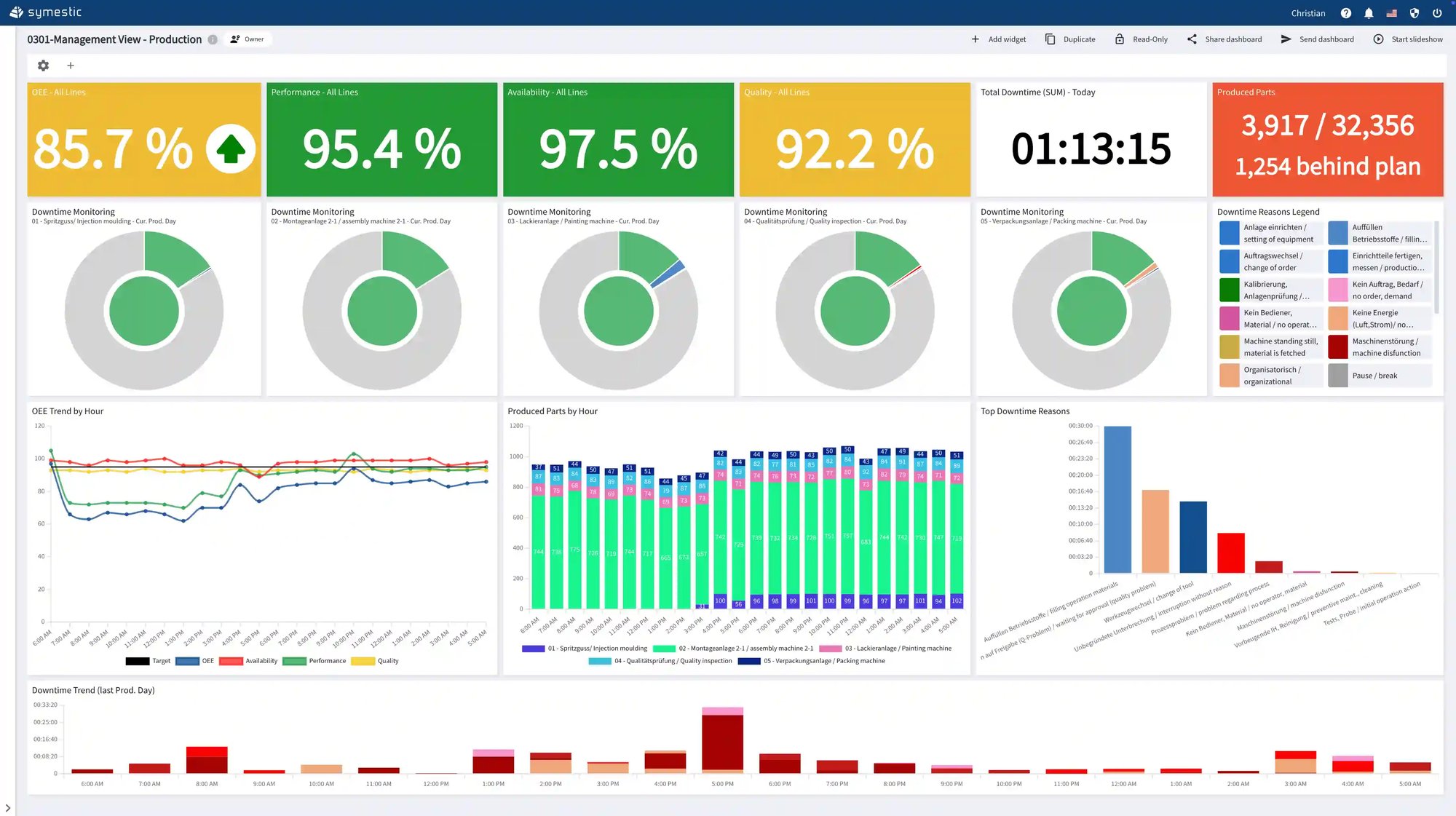

With SYMESTIC’s production monitoring software, manufacturers gain full real-time transparency into machine states, performance, downtime, cycle stability, throughput and quality – automatically and without manual data entry.

All relevant information is captured continuously, visualized instantly and analyzed in real time. This enables faster reactions, fewer disruptions and measurably more stable daily operations.

Real-Time Insights for Reliable Manufacturing Performance

Without real-time monitoring, disruptions remain hidden until they cause delays, output losses or quality issues.

SYMESTIC makes every machine event visible the moment it happens.

Teams see instantly which machines are running, where slowdowns occur and how performance evolves throughout the shift.

Live machine states, stop reasons, cycle times and production quantities update continuously and create a reliable, objective data foundation.

Automatic Data Capture Instead of Manual Reporting

Manual operator input leads to delays, inconsistencies and incomplete KPIs.

SYMESTIC captures machine and process data automatically and transforms it into accurate, real-time insights.

OEE values, availability, output and quality metrics are always up to date, enabling fact-based decisions instead of assumptions.

Dashboards Designed for All Roles in Manufacturing

The platform provides intuitive, role-specific dashboards for operators, supervisors and plant managers.

They show:

• live production output

• machine states and downtimes

• performance trends across shifts and lines

• root causes of losses

• early warnings for deviations

This shared transparency improves communication, prevents surprises and stabilizes day-to-day operations.