SPC Software: Real-Time Statistical Process Control

SYMESTIC SPC Software delivers real-time statistical process control with automated control charts, live trend detection and immediate deviation alerts.

Instead of reacting to defects after they occur, teams stabilize processes proactively and prevent quality issues before they reach the customer.

Why Modern Manufacturing Needs SPC Software

Manual SPC is slow, inconsistent and depends heavily on operator expertise.

Processes drift long before a defect becomes visible, and by the time traditional checks catch it, scrap and rework have already accumulated.

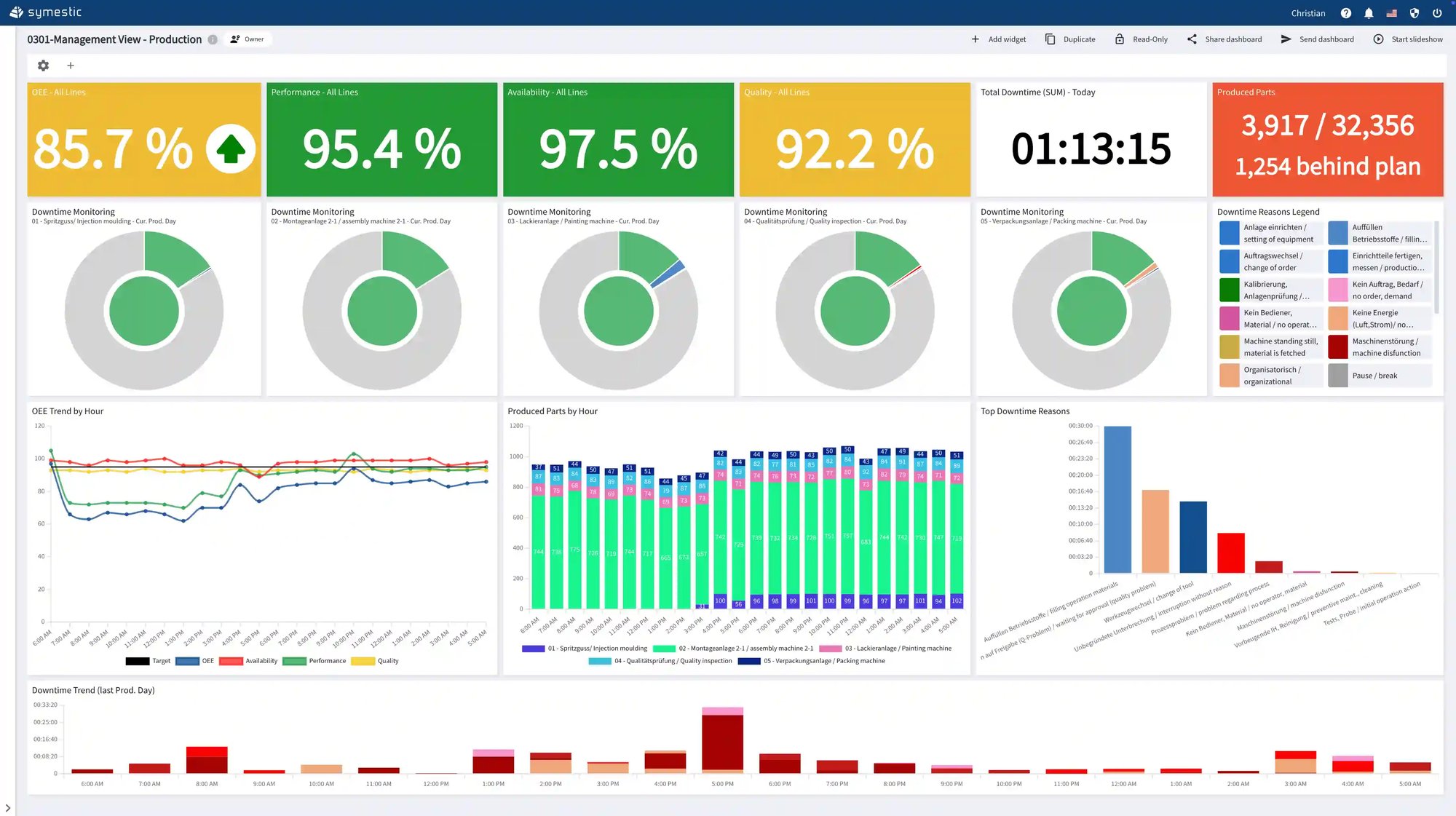

A digital SPC system continuously monitors machine and process data.

It identifies early trends, flags abnormal patterns and ensures that every deviation is visible the moment it emerges — enabling fast corrective action and dramatically reducing variability.

Automated Control Charts and Intelligent Analytics

SYMESTIC automatically generates control charts from real machine and measurement data.

Operators and quality engineers see upper and lower control limits, trends and stability indicators in real time, without manual data handling.

The system highlights shifts, drifts and process instability immediately.

Quality teams gain clear insight into whether a process is capable, predictable and within statistical boundaries.

Proactive Detection of Process Deviations

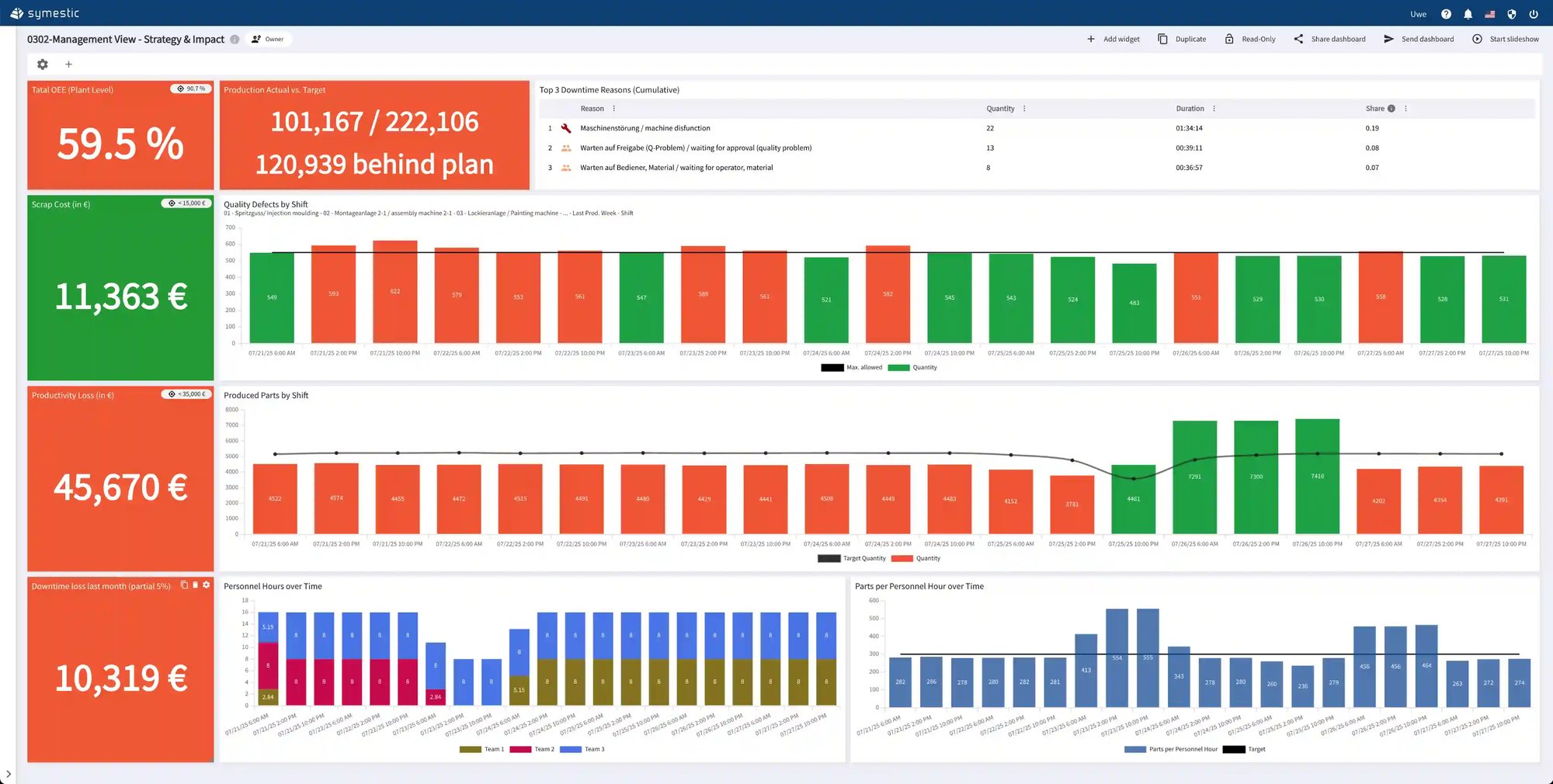

SYMESTIC SPC Software continuously analyzes data for anomalies.

When a parameter moves toward an unstable pattern, the system alerts teams instantly and provides relevant contextual information.

Instead of firefighting, production teams operate with foresight.

They correct issues early, stabilize processes faster and significantly reduce scrap and rework.

Integrated With the SYMESTIC Cloud MES Platform

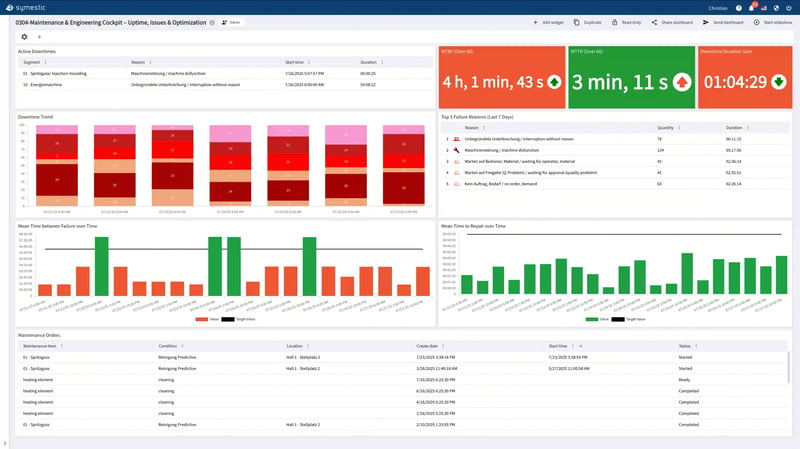

SPC is fully embedded into the SYMESTIC ecosystem.

Machine data, operator inputs, alarms and production orders flow together automatically, creating a single source of truth across the entire shop floor.

This eliminates interfaces, manual imports and data inconsistencies.

Teams work with high-quality, real-time insights — not outdated spreadsheets.

Faster Rollout, No Complex Configuration

SYMESTIC is cloud-native and ready to use within hours.

Existing measurement devices and machines can be connected quickly, allowing immediate SPC visibility.

Users do not need deep statistical knowledge; the system guides them with clear interpretation of patterns and deviations.

This lowers the barrier to adoption and maximizes impact from day one.

Achieve Measurable Quality Gains

Manufacturers using SYMESTIC SPC reduce defects, stabilize production and accelerate improvement cycles.

Real-time SPC ensures defects are prevented, not discovered late in the process.

Start your free 30-day trial and see how quickly digital SPC improves process capability and overall product quality.