Value Stream Analysis Software

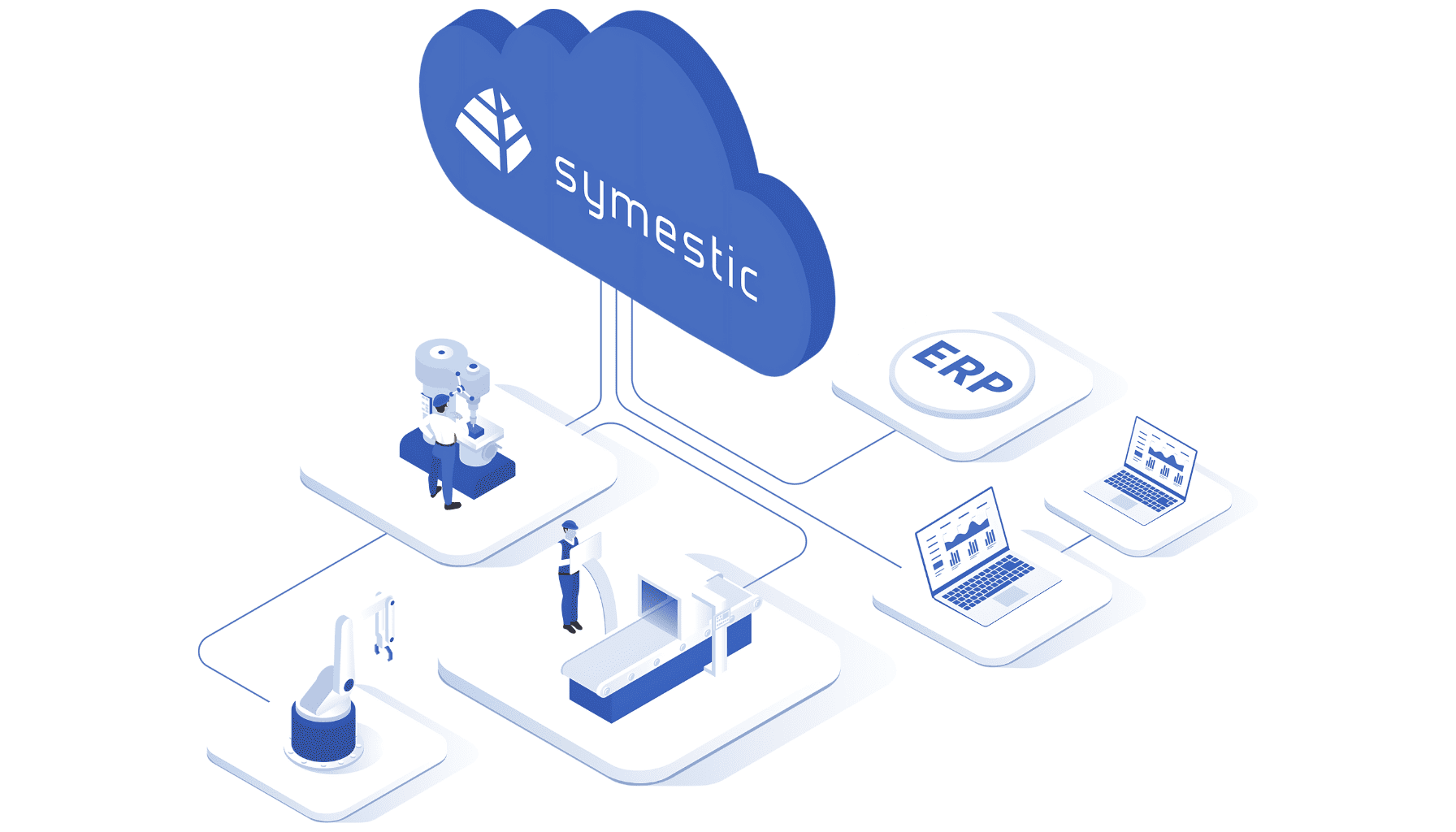

SYMESTIC’s Value Stream Analysis Software gives manufacturers real-time transparency into waste, bottlenecks and inefficiencies across their production processes.

By combining automatic data collection with intelligent analytics, the software turns hidden losses into actionable insights and enables continuous improvement at scale.

Identify Waste Across the Entire Value Stream

Manual value stream mapping is slow, incomplete and outdated the moment it's finished.

With automated, sensor-driven data collection, you gain accurate cycle times, real throughput visibility, and precise downtime classification — continuously and without manual effort.

This real-time perspective makes all seven types of waste visible and provides a reliable foundation for targeted Lean improvements.

.png?width=1792&height=1024&name=Lean-Production%20(3).png)

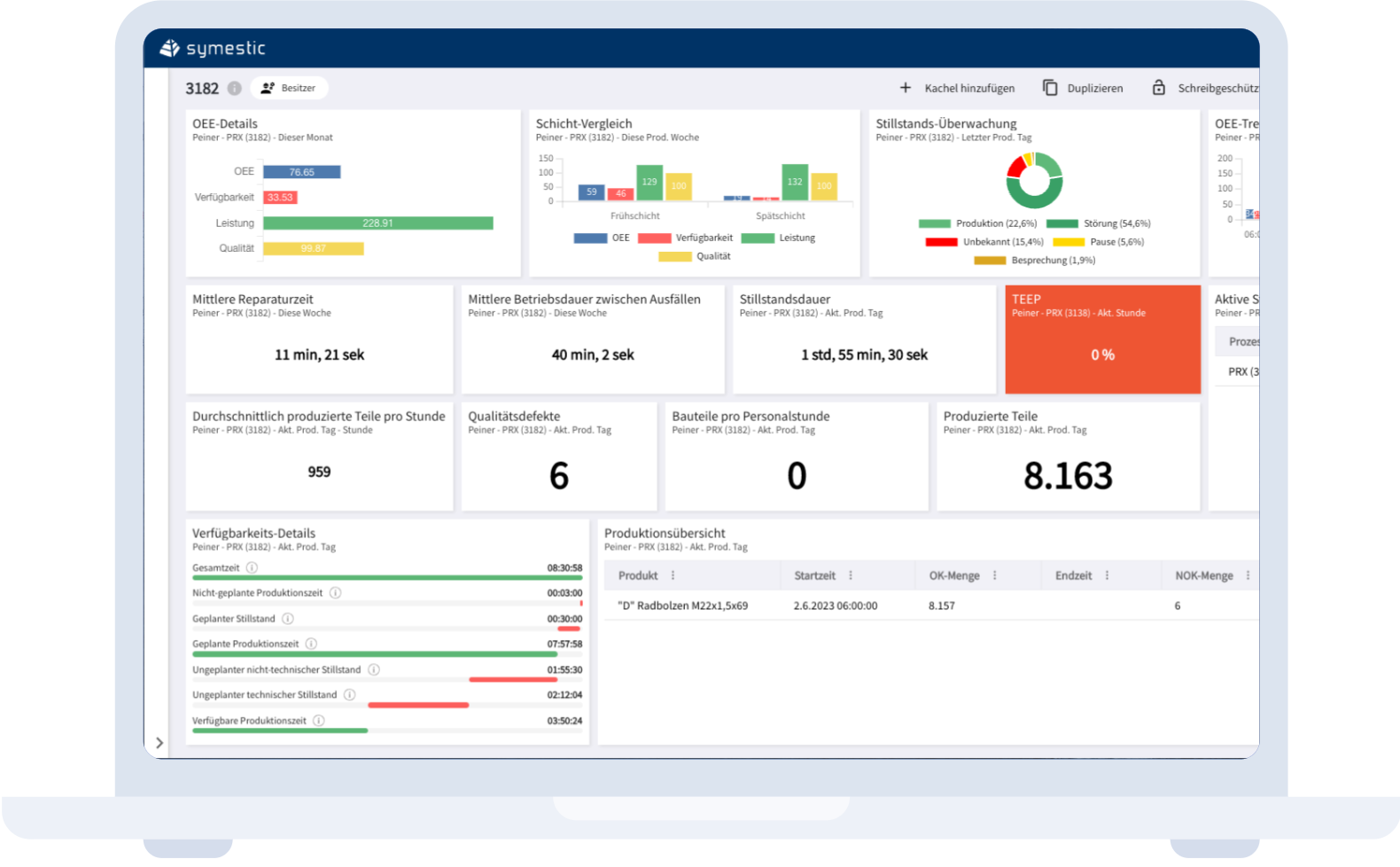

Analyze Throughput, Bottlenecks and Variability

SYMESTIC provides deep analytics that reveal the true drivers behind delays and productivity losses.

You see which steps slow down the flow, how much time is lost to waiting or transport, and how fluctuations impact the entire process.

With this continuous insight, you replace snapshots with a live, data-driven view of your entire value stream.

Intelligent Loss & Root Cause Analysis

The system calculates performance losses, highlights the largest waste categories and prioritizes improvement opportunities.

Pareto analyses, trend evaluations and automatic comparisons across shifts, machines and periods make it easy to focus on the areas with the highest impact.

Track Improvements and Prove ROI

SYMESTIC enables structured, digital improvement tracking.

Measures are documented, monitored and evaluated against real-time KPIs.

Before-and-after comparisons and ROI calculations show exactly how each optimization affects throughput and waste reduction.

This creates a closed loop between analysis, action and measurable results.