Manufacturing Execution System (MES) Explained

Definition

A Manufacturing Execution System (MES) controls, monitors, and documents production processes in real time.

It connects the shop floor with ERP systems, capturing operational and machine data to increase transparency, quality, and overall equipment effectiveness (OEE) while enabling fully paperless workflows.

Table of Contents

- What Is an MES?

- Core Functions of an MES (VDI 5600)

- Business Benefits of MES Software

- MES Architectures: On-Premises, Cloud-Hosted, Cloud-Native

- MES and ERP Integration (ISA-95)

- MES vs ERP vs SCADA vs MOM

- Modern Trends: SaaS, IIoT, Data Streaming, AI

- Implementation Best Practices

- MES FAQ

- Conclusion

What Is an MES?

A Manufacturing Execution System (MES) is a software solution that controls, monitors, documents, and optimizes manufacturing processes in real time. It serves as the link between the enterprise-level ERP system and the shop floor, connecting machines, sensors, and operators in a unified data flow.

The primary purpose of an MES is to track and manage the complete transformation of raw materials into finished goods. It captures operational, machine, and quality data directly from production equipment, processes it in real time, and makes it available for data-driven decision-making.

Key characteristics of an MES:

- Real-time transparency across orders, machine status, material flow, and product quality

- Execution of production plans through digital work instructions and operator guidance

- Full traceability of all process steps for quality assurance, compliance, and audits

- Continuous optimization by identifying bottlenecks, scrap causes, and improvement potential

An MES closes the gap between planning and actual production, turning raw data into actionable insight for smarter manufacturing.

An MES answers a central question:

How is production performing right now — and how efficiently are resources being used?

Through seamless integration with machine data collection (MDC) and production data collection (PDC), an MES provides precise, real-time insights into order progress, downtime, and performance metrics. This creates the foundation for a fully transparent and automated production environment.

Core Functions of an MES

The functions of a Manufacturing Execution System are defined in many companies according to the VDI Guideline 5600, which is widely recognized as the industry standard. The goal is to make production transparent, efficient, and error-free by connecting all relevant processes in real time.

Key Functions of a Manufacturing Execution System (MES):

- Detailed scheduling and control

Translates production plans into concrete work orders considering capacity, material availability, and workforce. - Equipment management

Monitors machines, tools, and production assets to ensure availability, performance, and proper maintenance. - Material management

Ensures timely material supply and manages in-process and intermediate inventories. - Workforce management

Matches production orders with employee availability, skills, and qualifications. - Data collection

Automatically or manually records machine, process, and operational data in real time. - Quality management

Monitors process and product quality, documents results, and enables immediate action in case of deviations. - Information management

Provides and connects all relevant production information from work orders and machine data to quality reports across the entire manufacturing process.

Main Benefits of a Manufacturing Execution System (MES)

A Manufacturing Execution System (MES) helps manufacturers gain real-time visibility, improve efficiency, and reduce production costs. By collecting and analyzing shop-floor data, MES software connects machines, people, and processes - turning production into a transparent, data-driven operation.

1. Real-time transparency across production- Continuous tracking of machines, orders, and quality data

- Clear visibility into downtime, scrap, and utilization rates

- Accurate insights for performance analysis and continuous improvement

- Optimized use of equipment, labor, and materials

- Shorter setup, waiting, and lead times

- Improved Overall Equipment Effectiveness (OEE) through better scheduling and control

- Real-time process and quality monitoring

- Instant detection of deviations or non-conformities

- Digital traceability for audits, compliance, and customer documentation

- Precise feedback on material consumption and scrap

- Lower work-in-progress (WIP) and optimized stock levels

- Less rework, waste, and unplanned downtime

- Bridges ERP and shop-floor operations

- Enables paperless workflows and digital operator guidance

- Supports predictive maintenance and IIoT-driven optimization

Modern MES software delivers measurable business value - improving OEE, product quality, and throughput while creating a connected, agile manufacturing environment.

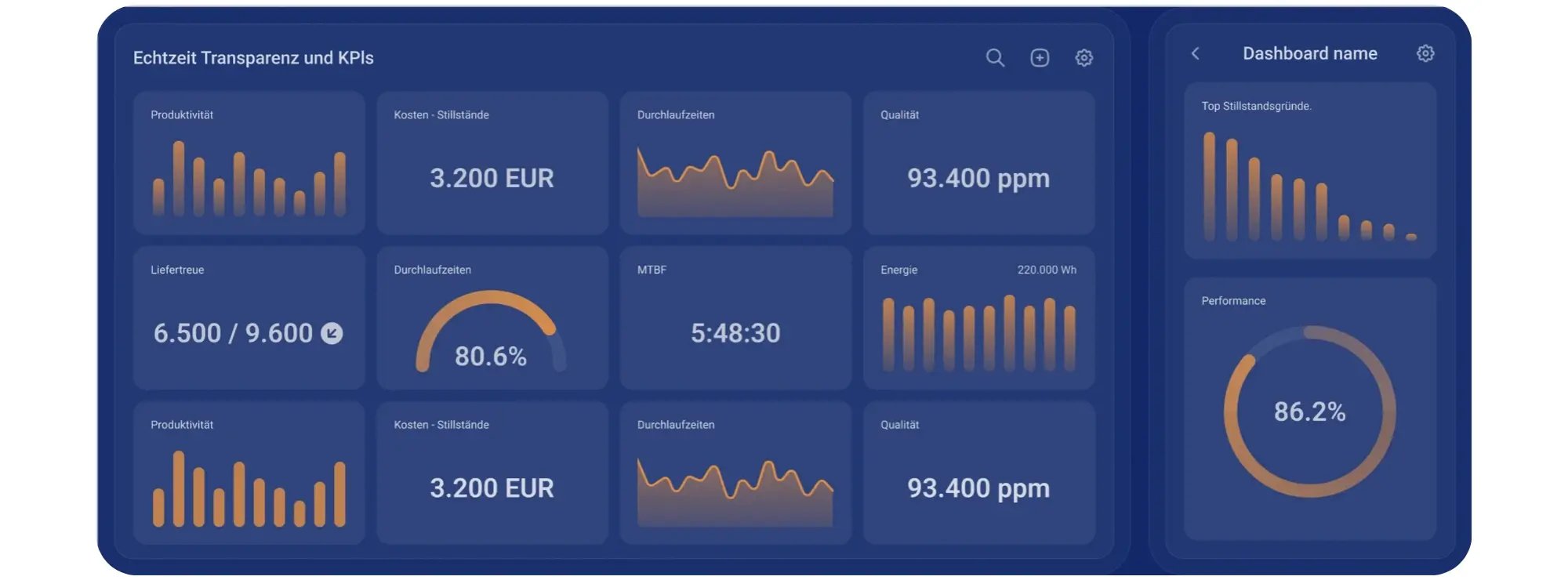

The dashboards demonstrate how SYMESTIC transforms production data into actionable insights. This makes a Manufacturing Execution System more than just a monitoring tool — it becomes the digital cockpit of modern manufacturing.

In the next section, we explore the different types of MES architectures and how they impact scalability, cost, and implementation speed.

Types of MES Architectures

Choosing the right MES architecture is a key success factor. According to the VDI Guideline 5600 and market research by IoT Analytics, the trend is clearly moving toward cloud-native MES solutions, while traditional on-premises systems are steadily declining in relevance.

Overview of the three main MES architectures:

On-Premises MES

Characteristics: Installed locally in the company’s data center with full control over data.

Advantages: High customization, complete data ownership, and offline operation possible.

Disadvantages: Long implementation times, high capital expenditure (CAPEX), and complex maintenance or updates.

Cloud-Hosted MES (Lift & Shift)

Characteristics: Conventional MES software hosted on a cloud infrastructure.

Advantages: Reduced internal IT workload and faster scalability.

Disadvantages: Not a true cloud architecture, limited flexibility, often costly licensing.

Cloud-Native MES

Characteristics: Purpose-built for the cloud, based on modular microservices.

Advantages: Fast implementation, SaaS subscription instead of heavy investment, easy integration, and multi-site scalability.

Disadvantages: Vendor dependency and reliance on internet connectivity.

The market is clearly shifting toward cloud-native MES platforms, as they best support digital transformation, shorten time-to-value, and provide long-term scalability for modern manufacturing.

MES and ERP Systems – A Powerful Combination

An MES alone provides real-time visibility and control on the shop floor, while an ERP system handles planning, resources, and financial management. Only when both systems work together does their full value unfold.

ERP (Enterprise Resource Planning): defines what needs to be produced — quantities, schedules, and resources.

MES (Manufacturing Execution System): defines how it is produced — sequencing, execution, and optimization of materials, machines, and workforce.

Why this integration matters

ERP delivers the strategic plan, while MES translates it into actionable production processes. In return, MES feedback — such as OEE, downtime, and quality data — flows back into ERP, improving planning accuracy and costing.

Example

If the ERP system schedules 10,000 parts to be produced by Friday, the MES continuously checks machine availability, speed, and bottlenecks. It dynamically adjusts workflows and reports whether the deadline is achievable or if rescheduling is required.

International standards such as ISA-95 (IEC 62264) define the interface between MES (Level 3) and ERP (Level 4) as a cornerstone of modern production IT. This seamless integration enables real-time transparency, consistent data flows, and the digital backbone required for Industry 4.0 manufacturing.

MES vs ERP vs SCADA vs MOM

In practice, terms like MES, ERP, SCADA, and MOM are often used interchangeably, which can lead to confusion. Understanding their distinctions is essential for selecting the right system architecture and ensuring a successful implementation.

MES vs ERP

ERP (Enterprise Resource Planning) operates at the business-management level, handling planning, procurement, finance, HR, and supply chains.

MES (Manufacturing Execution System) operates on the shop floor, focusing on real-time control, monitoring, and optimization of production processes.

In short: ERP defines what to produce, MES ensures how it is produced.

MES vs SCADA

SCADA (Supervisory Control and Data Acquisition) is primarily a monitoring and control system for machines and equipment, collecting process data such as temperature, pressure, or runtime.

MES goes further — it links this process data with orders, materials, personnel, and quality objectives to make the entire production process transparent and controllable.

SCADA provides signals, MES turns them into actionable information.

MES vs MOM

MOM (Manufacturing Operations Management) is a broader term encompassing all operational manufacturing systems — including MES, quality management, maintenance, and laboratory systems.

MES is a core component within MOM, often seen as the central platform connecting and coordinating these functions.

When discussing MOM, it refers to the overall manufacturing operations framework — with MES as its heart.

For a deeper understanding, refer to the ISA-95 standard by the International Society of Automation, which defines the roles, boundaries, and integration points between ERP, MES, and shop-floor control systems.

Modern Trends: SaaS, IIoT, Data Streaming, and AI

The digital transformation of manufacturing is reshaping the MES market at its core. Three major developments stand out:

Cloud and SaaS

More and more manufacturers are migrating their MES to the cloud. According to a study by IoT Analytics, 29% of manufacturing companies plan to operate their MES — or a significant portion of it — in the cloud within the next two years.

The advantages are clear: shorter implementation times, flexible scalability, and predictable subscription-based costs.

SYMESTIC focuses on exactly this approach, offering a cloud-native MES that is ready to use within hours — without complex IT projects or heavy infrastructure.

Market growth

The global MES market is expanding rapidly. According to The Insight Partners, it is expected to grow from USD 16.66 billion in 2024 to USD 36.13 billion by 2031, representing a compound annual growth rate (CAGR) of 11.8%.

The cloud MES segment is growing even faster — from USD 10.64 billion in 2024 to USD 24.13 billion by 2031 (CAGR 12.5%).

These trends underline a clear direction: cloud-native, data-driven MES platforms will define the next generation of manufacturing software — faster, more scalable, and aligned with Industry 4.0.

IIoT, Data Streaming, and AI

Beyond cloud adoption, IIoT connectivity and real-time data streaming are shaping the next generation of MES platforms. Production data is no longer just collected — it is continuously processed and visualized in live dashboards, alerts, and analytical reports.

AI-driven algorithms detect patterns, predict equipment failures, and optimize quality by identifying root causes automatically.

SYMESTIC integrates these capabilities directly into its cloud-native MES platform, enabling manufacturers to analyze OEE, machine performance, and quality KPIs in real time — across multiple sites and without data silos.

Modern MES systems have evolved from traditional control tools into the digital nervous system of the Smart Factory.

Manufacturers that adopt SaaS- and cloud-based MES solutions today gain a lasting competitive edge through agility, scalability, and actionable production intelligence.

Implementation: Best Practices

Implementing a Manufacturing Execution System (MES) often determines the success or failure of digital manufacturing initiatives. Projects rarely fail because of the technology itself — but rather due to unclear goals, poor integration, or a lack of user adoption. Following proven best practices helps minimize risk and accelerate the return on investment (ROI).

1. Define goals and requirements

An MES project should start with clear business objectives — improving efficiency, enhancing quality, and ensuring compliance. These goals must be documented and translated into measurable technical requirements.

2. Involve key stakeholders early

Production management, IT, quality assurance, logistics, and executives must all be engaged from the beginning. A designated MES key user helps align departments and build user acceptance.

3. Choose the right architecture

Whether on-premises, cloud-hosted, or cloud-native, the chosen architecture determines flexibility, cost, and scalability. Studies show a strong market shift toward cloud-based MES implementations.

4. Start small, scale fast

Begin with a pilot line or a single site before scaling across the organization. This approach helps identify issues early and achieve quick wins.

5. Focus on training and change management

Technology alone is not enough. Successful adoption requires well-trained users and clear communication to reduce resistance and ensure long-term engagement.

6. Ensure seamless integration

The real value of MES comes from integration. Interfaces with ERP systems (such as SAP) and other IT/OT layers should be planned early, using open standards like ISA-95 or OPC UA.

7. Maintain data quality

“Garbage in, garbage out” applies here as well. Reliable KPIs and AI-driven insights require clean master data, standardized collection processes, and clear governance rules.

8. Embed continuous improvement

MES implementation is not a one-time project but an ongoing process. Dashboards, reports, and KPIs should be reviewed regularly to identify and act on new optimization opportunities.

MES FAQ

What is an MES?

A Manufacturing Execution System (MES) is a software solution that controls, monitors, and documents production processes in real time. It connects the ERP level with the shop floor, ensuring transparency, efficiency, and quality across manufacturing operations.

What are the main benefits of an MES?

An MES increases productivity by reducing downtime, improves product quality through real-time analytics, and lowers costs by optimizing processes. It also enables full traceability and supports compliance with industry regulations.

What is the difference between MES and ERP?

An ERP system plans and manages resources such as materials, personnel, and finances. An MES executes these plans on the shop floor by controlling machines, capturing live production data, and feeding performance results back to the ERP system.

What is the difference between MES and SCADA?

SCADA (Supervisory Control and Data Acquisition) systems monitor and control individual machines or processes. MES goes beyond that — integrating multiple lines and plants, connecting with ERP systems, and providing higher-level KPIs such as OEE.

Which industries use MES software?

MES is used across nearly all manufacturing sectors: automotive, pharmaceuticals, food & beverage, electronics, aerospace, and consumer goods. Every industry benefits from real-time visibility, better quality control, and higher efficiency.

What functions are included in an MES?

According to VDI 5600, MES core functions include detailed scheduling, production and machine data collection, quality management, material management, workforce management, and information management. Modern cloud MES systems extend this with IIoT, AI, and data streaming capabilities.

How is an MES implemented?

Best practice is a phased approach: define clear goals, involve all stakeholders, choose the right architecture (e.g., cloud-native SaaS), start with a pilot line, provide training, and scale step by step. Seamless integration with ERP systems is critical for success.

How much does an MES cost?

Costs depend on the vendor and system architecture. Traditional on-premises MES requires high upfront investment. Cloud-native MES platforms like SYMESTIC use a SaaS model — offering predictable monthly pricing, quick deployment, and easy scalability.

(Learn more about our pricing on the SYMESTIC website.)

Conclusion

A Manufacturing Execution System (MES) is far more than a traditional production control tool — it has become the digital backbone of the Smart Factory. Manufacturers using MES gain real-time transparency, increase their OEE, improve product quality, and reduce production costs.

Market trends clearly show a shift toward cloud-native MES solutions. They are faster to implement, easily scalable, and offer a transparent SaaS-based cost model. Companies that adopt these technologies early secure lasting competitive advantages in their digital transformation.

SYMESTIC provides a modern, cloud-native MES that is ready for use within days — without complex IT projects. Production data is automatically collected, analyzed in real time, and displayed in powerful dashboards across all sites, ensuring seamless data flow and maximum visibility.

Manufacturers ready to future-proof their operations should act now and experience how quickly SYMESTIC delivers measurable results.